上海维宏电子科技股份有限公司

SHANGHAI WEIHONG ELECTRONIC TECHNOLOGY CO., LTD.

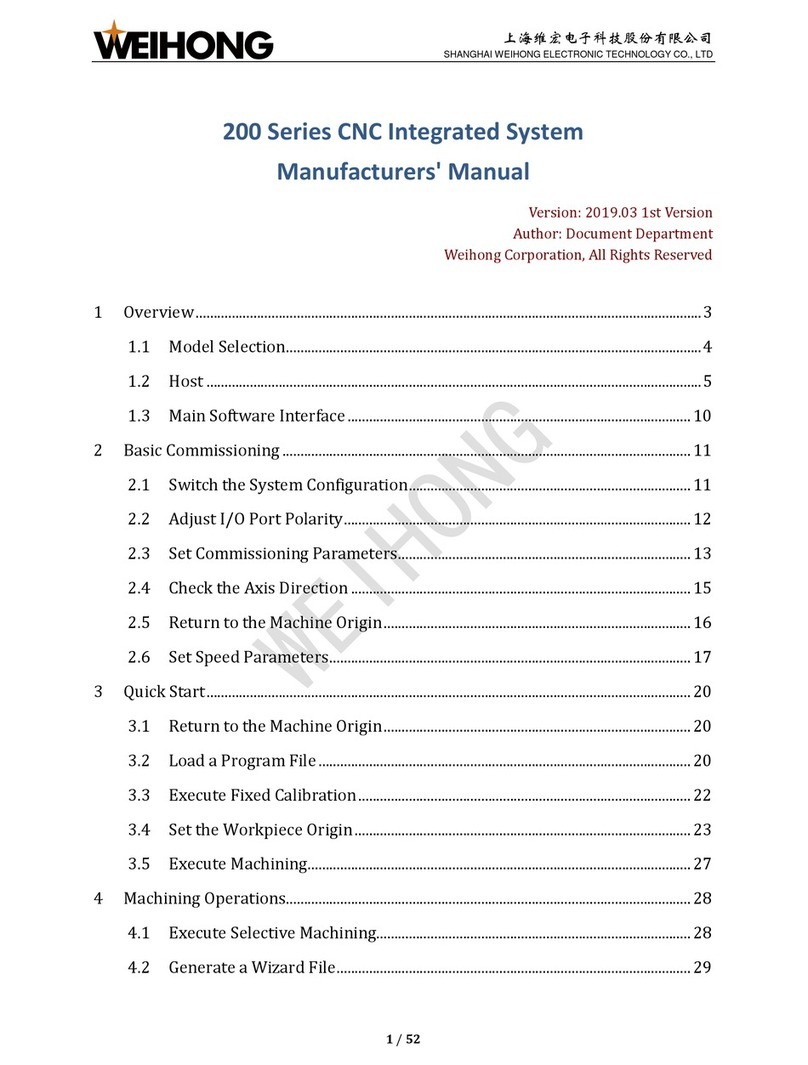

3.4 Return to the Center ...................................................................................................... 32

3.5 Set Automatic Centering............................................................................................... 32

4Object Operations........................................................................................................................ 34

4.1 Drawing Operations....................................................................................................... 35

4.2 Auxiliary Editing Operations ...................................................................................... 38

4.3 Basic Editing Operations.............................................................................................. 44

4.4 Preprocessing Operations ........................................................................................... 62

5Technics .......................................................................................................................................... 68

5.1 Set Fill or Unfill ................................................................................................................ 68

5.2 Set a Lead Line ................................................................................................................. 69

5.3 Change the Machining Direction............................................................................... 73

5.4 Change the Machining Order...................................................................................... 75

5.5 Compensate Kerf............................................................................................................. 78

5.6 Execute Instant Setting................................................................................................. 79

5.7 Set Scan Cutting ............................................................................................................... 81

5.8 Add Cooling Points ......................................................................................................... 83

5.9 Add Release Angles ........................................................................................................ 85

5.10 Add Chamfer ................................................................................................................. 86

5.11 Bridge Objects .............................................................................................................. 88

5.12 Execute Micro Joint .................................................................................................... 89

5.13 Explode Micro Joint.................................................................................................... 91

5.14 Chop Objects ................................................................................................................. 92

5.15 Execute Ring Cut ......................................................................................................... 93

5.16 Do Clearing .................................................................................................................... 94

6Layer Function.............................................................................................................................. 95

6.1 Interface Overview......................................................................................................... 96

6.2 Layer Operations............................................................................................................. 97