PAGE 8 OF 8

Issue 2

JANUARY 2005

OPERATING INSTRUCTIONS

MACHINE INSTALLATION

Secure the TWL 1500 onto a sturdy bench making sure there is enough room

around the unit for the display stand and for the loading device to move freely along

the length of the stand.

IMPORTANT NOTES

a. Ensure that the bolts fastening the transducer plate to the stand are torque

tightened to 20 N.m.

b. Always ensure loading device is firmly clamped before loading the rig.

c. Always ensure the transducer leads are not caught up in the mechanism.

d. To ensure trouble free use, periodically check that the screw thread and guide

rails on the loading device are lubricated with a good quality machine oil.

WRENCH INSTALLATION

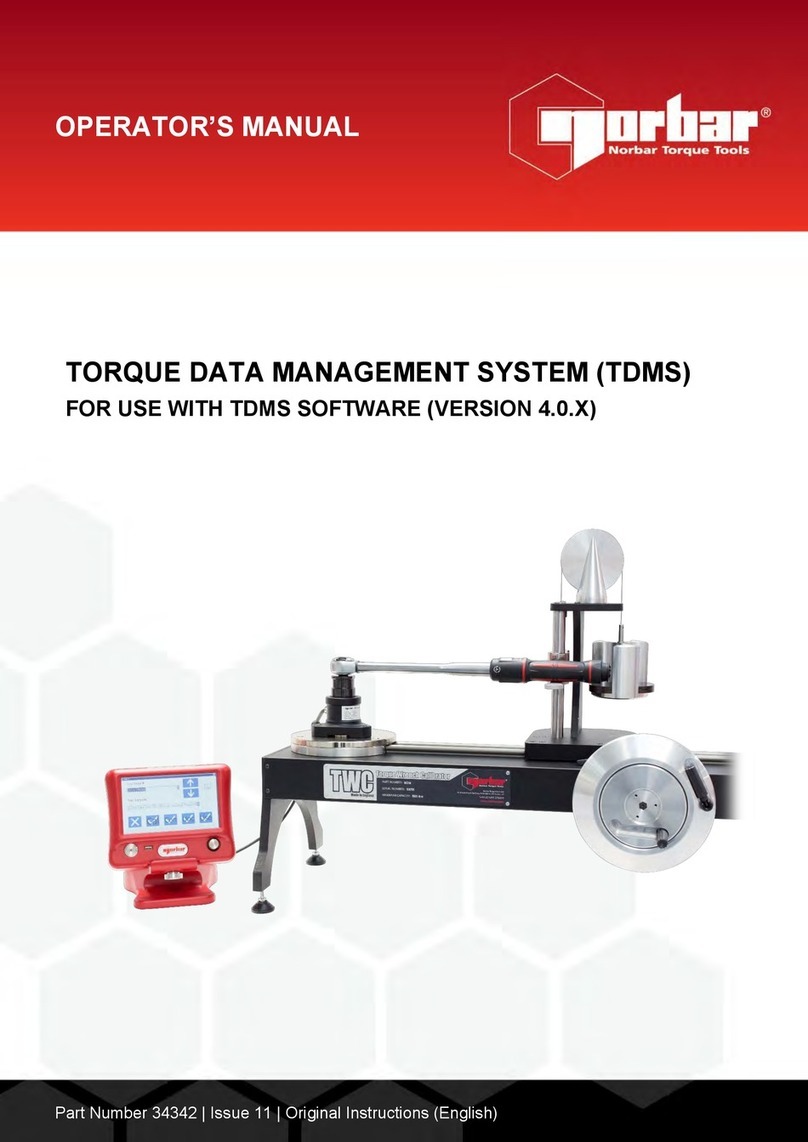

1. Slide the loading device assembly along the reaction bar far enough to allow

clearance for the torque wrench to be installed in the TWL1500.

2. Select the lowest capacity torque transducer to cover the wrench to be tested.

3. With the handle of the wrench running along the length of the reaction bar, mount

the torque wrench to be tested in the female square drive of the selected torque

transducer.

4. Slide the loading device assembly along the reaction bar so that the support bobbin

is reacting against the normal hand position of the wrench. This is usually the

centre of the wrench hand grip.

5. If the wrench is fitted with a square drive ratchet ensure that the orientation of the

square drive allows maximum travel of the wrench handle by the support bobbin.

6. Orientate the support bobbin so that the wrench maintains a horizontal position

during testing.

7. Firmly tighten the clamp plate of the loading device before loading the rig.

8. Turn the hand-wheel smoothly to apply load to the torque wrench.

9. Follow the appropriate calibration procedures for the torque wrench being tested.

NOTE: In the case of a ratchet wrench with push through square drives, it is

important to ensure the square is operating on the correct side of the

ratchet.