SAFETY

IMPORTANT: DO NOT OPERATE THE TOOL BEFORE READING THESE INSTRUCTIONS.

FAILURE TO DO SO MAY RESULT IN PERSONAL INJURY OR DAMAGE TO THE TOOL.

This tool is intended for use with threaded fasteners.

The use of proper ear protectors is recommended.

Do not use these tools in potentially explosive atmosphere as they contain grease, which may cause an

explosion hazard in the presence of pure oxygen. These tools also contain aluminium alloy components

which may cause a hazard in certain explosive environments.

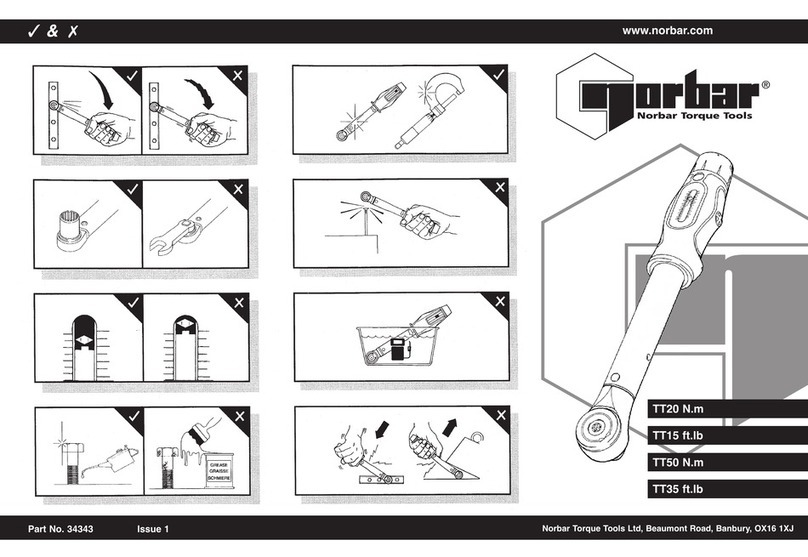

Unexpected tool movement due to reaction forces or breakage of drive square or reaction bar may cause

injuries.

Isolate the tool from all energy sources before changing or adjusting the drive square or socket.

There is a risk of crushing between the reaction bar and work piece.

Keep hands away from reaction bar.

Keep hands away from tool output.

Keep loose clothing, hair, etc. from being caught in any rotating part of the tool.

These tools require a reaction bar. See section on Torque Reaction.

Ensure all hoses are correctly fitted before switching on the air supply. This avoids the risk of injury by

whipping air hoses.

Unexpected direction of drive square movement can cause a hazardous situation.

Use only sockets and adaptors which are in good condition and are intended for use with power tools.

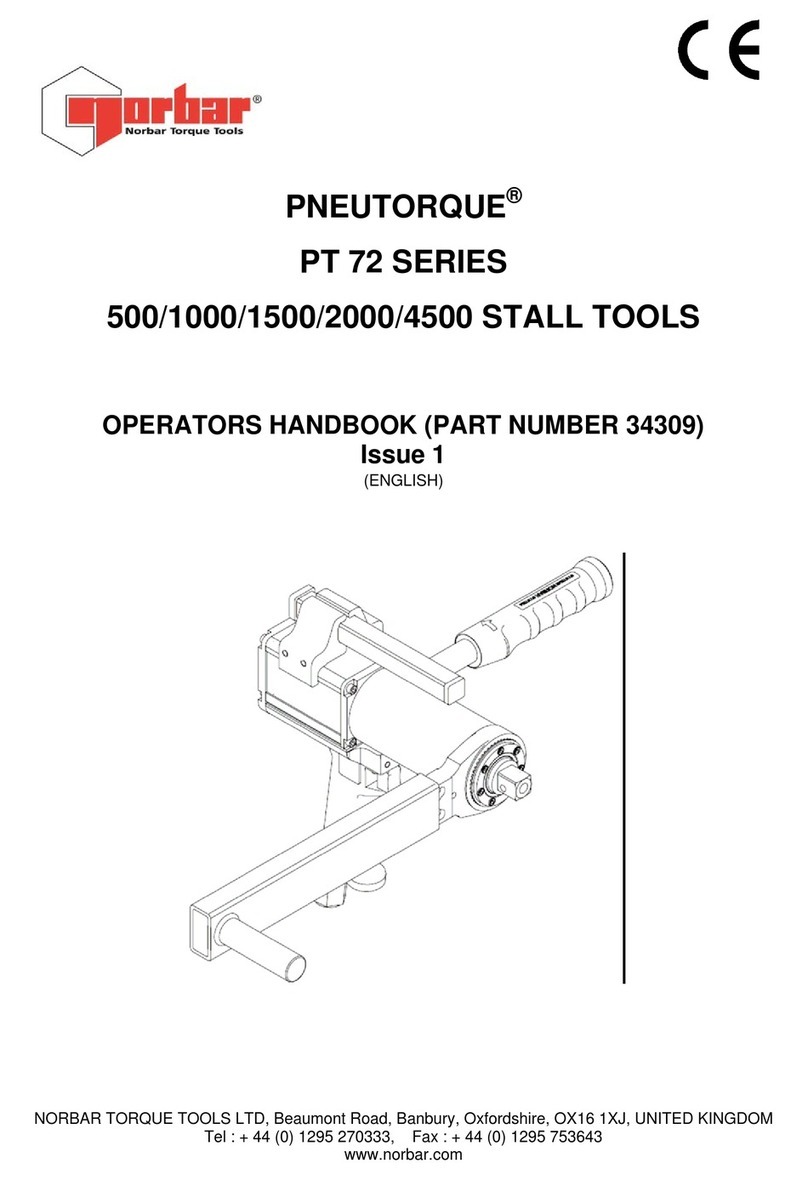

Pneutorque® Wrenches are non-impacting, torque controlled threaded fastener tightening tools and must

always be operated with the following:-

Clean dry air supply with a minimum flow of 19 litres/sec (40 CFM).

Lubro Control Unit or similar Filter, Regulator and Lubricator Unit 1/2” Bore (12 mm).

Impact or high quality sockets.

Reaction bar.