ColorMax®2 Powder Coating System with

Encore®Venturi Feed Center - Color Change Procedure

Color Change Tasks: Cyclone Side Operator Color Change Tasks: Non-Cyclone Side Operator

1. Encore®manual guns: Disconnect the powder hose from the

spray gun and connect it to the purge port.

Prodigy®manual guns: Hang up the spray gun so it is pointing into

the booth.

Sure Coat®manual guns: Purge the spray gun, then disconnect

the powder hose and insert the end of the hose into the booth.

2. Move to the feed center

a. Make sure the damper switch is set to AUTO.

b. Turn OFF the bulk feed pump (if equipped), the reclaim pump,

and the sieve.

c. Disconnect the bulk and reclaim hoses from the sieve and

connect them to the purge ports.

d. At the bulk feed system, remove the siphon hose from the

powder supply and connect it to the purge port.

e. Unclamp the sieve deck and turn the pan chute so it points

toward the back of the feed center.

f. Re-clamp the deck.

g. Turn ON the bulk feed pump (if equipped), reclaim pump, and

color change switch.

NOTE: Lances will move up automatically.

h. Turn OFF the vibratory table (if used).

i. If used, disconnect the fluidizing air tubing from the hopper.

j. Remove the hopper from the feed center.

k. Blow off the lower parts of the lances and the purge manifold.

Make sure the other operator is clear of the

spray guns.

l. Turn the purge switch to the GUN PURGE position.

m. Unclamp the sieve.

n. One at a time, remove the deck, screen, and pan and blow

them clean. Remove the gasket from the screen and clean it.

o. Set the sieve components outside the feed center.

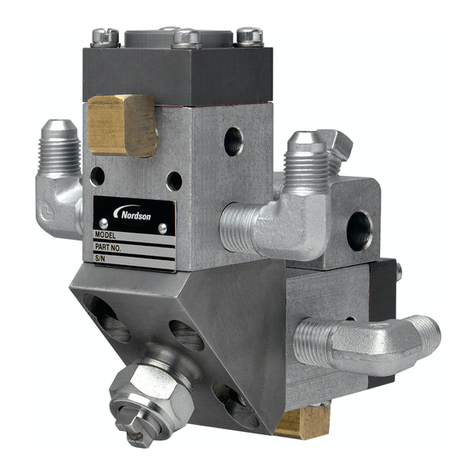

p. Lance assemblies equipped with hose manifolds:

i. When the internal gun purge is done, raise the lances

halfway, unclamp the hose manifold, and blow clean the

manifold and pump outlet nozzles.

ii. Blow down into the nozzles, and up into the lance ports

from the bottom of the lances.

1 of 2

Lances automatically move down onto

the purge manifold, are clamped in

place, and the internal gun purge

begins.

© 2015 Nordson Corporation. All Rights Reserved.

Pan Chute

Purge Port

Fluidizing Tubing

Purge Port

1. Press the ancillary equipment clean cycle button. The gun movers go to their home position and the exterior of

the automatic spray guns are blown off.

2. Move to the entry end of the booth

a. Close and latch the booth entry doors.

3. Return to the non-cyclone side operator platform

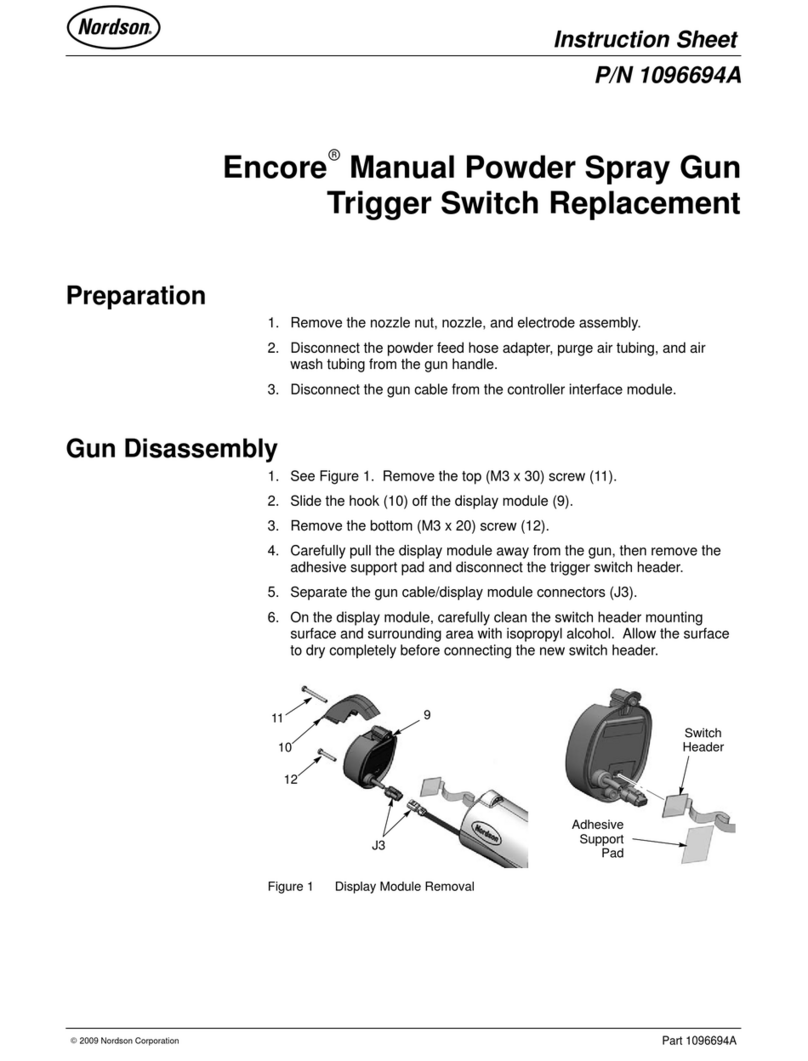

a. Encore®manual guns: Disconnect the powder

hose from the gun and connect it to the purge port.

Remove the nozzle and electrode holder and blow

them clean. Point the blow gun into the powder inlet

and blow out the gun. Blow off the gun exterior.

Prodigy®manual guns: Blow the gun clean and

hang it up so it is pointing into the booth.

Sure Coat®manual guns: Purge the gun, then

disconnect the powder hose and insert the end of the

hose into the booth. Remove the nozzle and blow it

clean. From the hose inlet, blow out the powder path.

Install the nozzle on the gun then hang it up.

b. Close and latch the operator door.

4. Move to the exit end of the booth – Perform Coarse

Cleaning

a. Open the operator door and blow off the floor duct

while walking toward the entrance.

b. Blow off the AeroDecks™ and lift them open.

c. Blow off the stainless steel riser door, then exit the

booth.

5. Move to the cyclone side operator platform

a. Clean the spray gun and hang it up as described

previously.

b. Close and latch the operator door.

c. Move the booth off-line. (Roll-on/roll-off booth)

a. Make sure all operators are clear of the

spray guns.

6. Move to the exit end of the booth – Perform Finish

Cleaning

a. Blow off the door and exit opening sills. Open the

door and blow off the entry sills.

Purge Port

Disclaimer: Due to the different number of tasks and explanations required for each

operator, the tasks cannot line up exactly on paper. Exact coordination is approximate.

Where it is CRITICAL for operators to coordinate tasks, it is noted in the procedure.

Caution: For all blow-off procedures,

use the grounded blow-off gun and

hose assembly provided by Nordson.

1605545-03