Norton 8380 User manual

Other Norton Door Opening System manuals

Norton

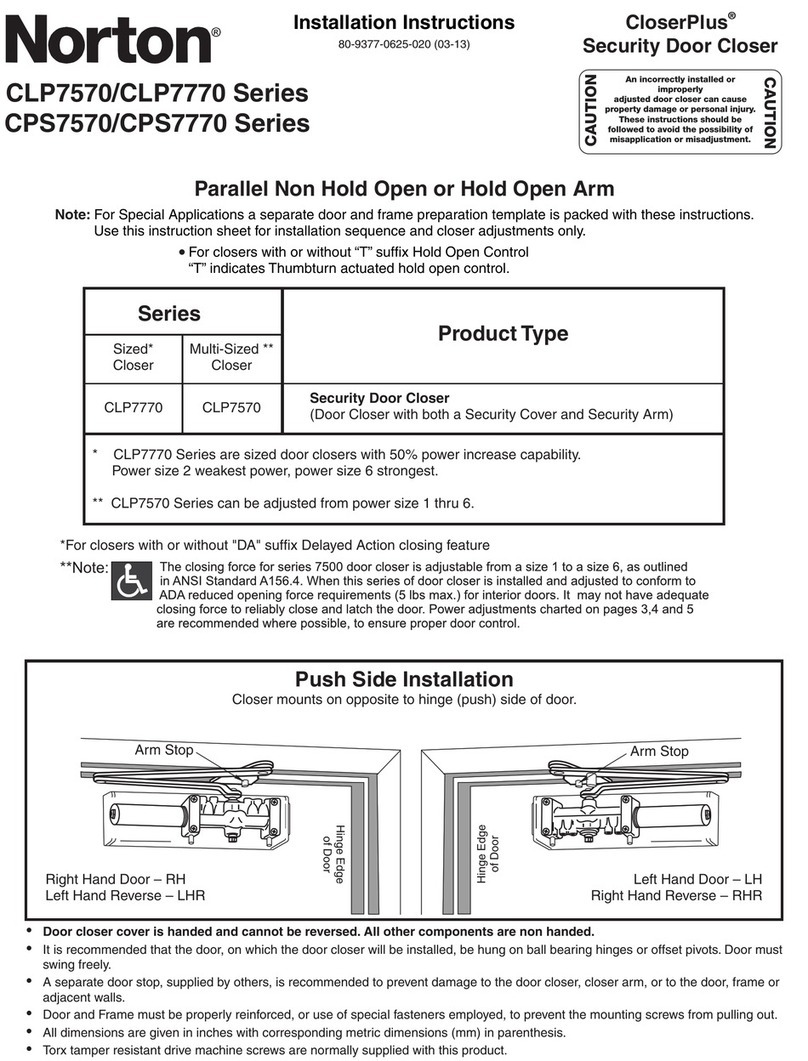

Norton CloserPlus CLP7570 Series User manual

Norton

Norton 8000 Series User manual

Norton

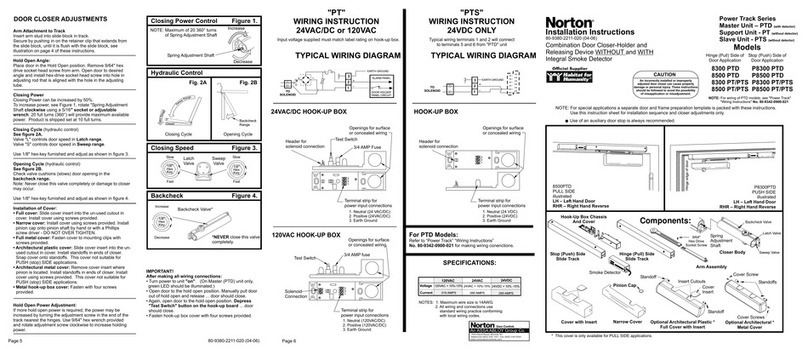

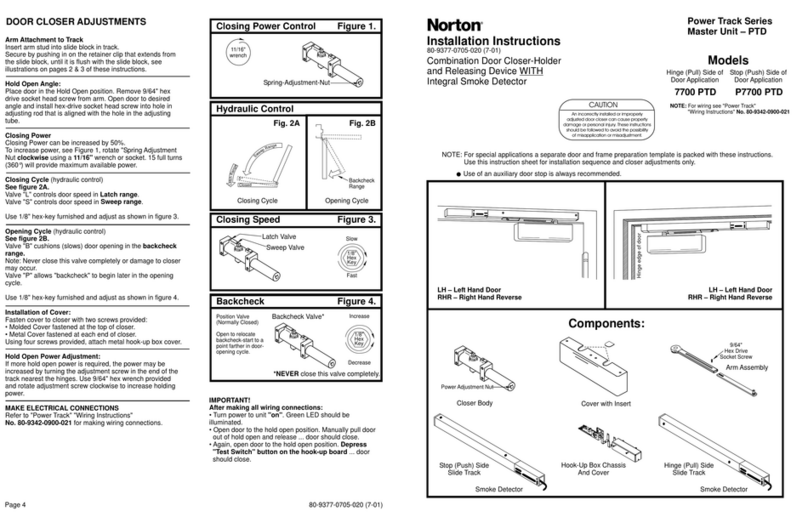

Norton Power Track Series User manual

Norton

Norton 6900 PowerMatic User manual

Norton

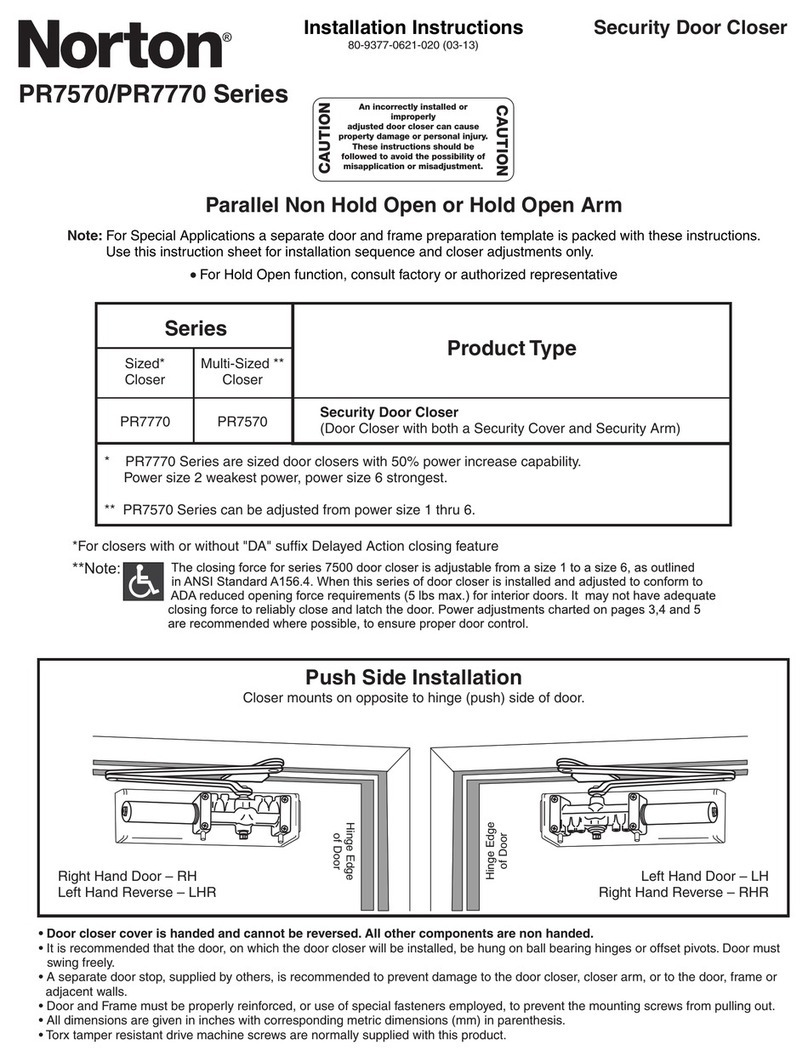

Norton PR7570 Series User manual

Norton

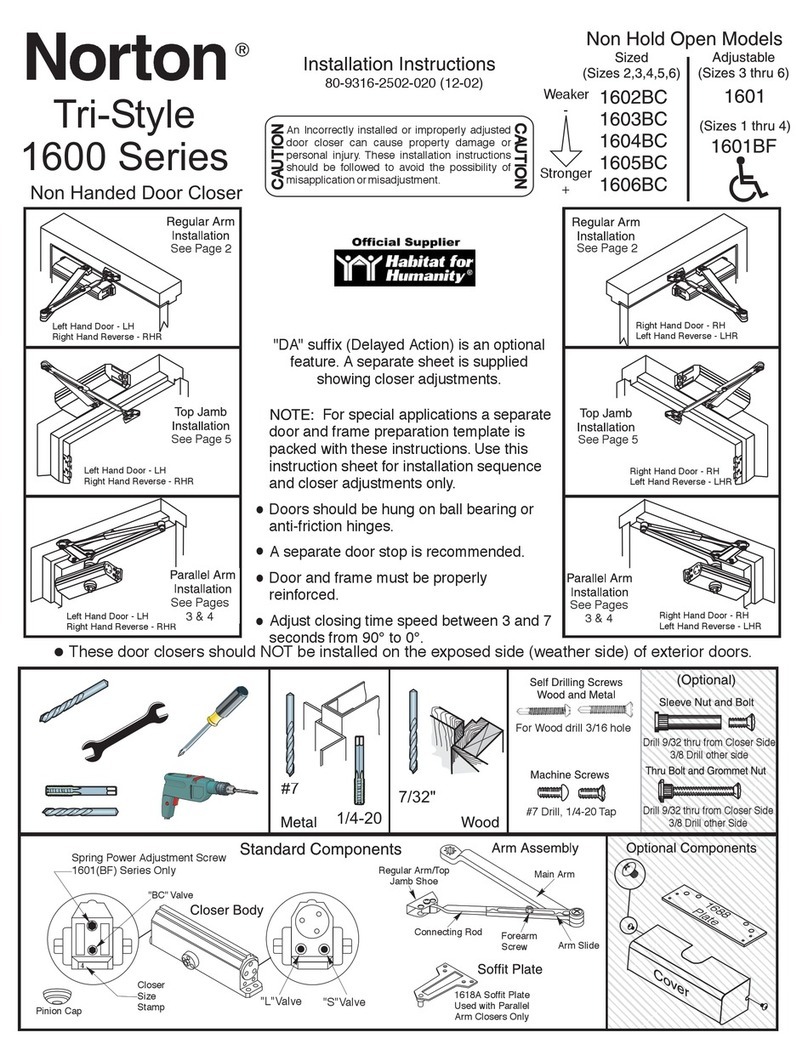

Norton 1600 Series User manual

Norton

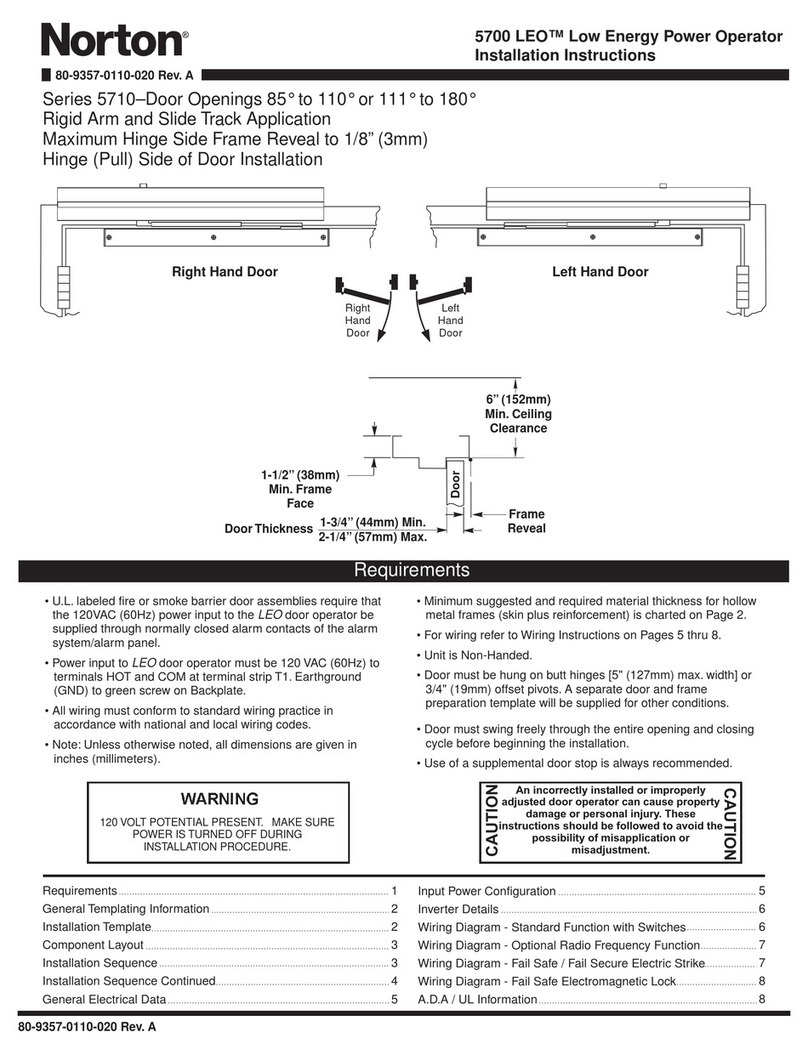

Norton LEO 5710 Series User manual

Norton

Norton Tri-Style 1600 Series User manual

Norton

Norton Power Track Master Unit PTD Series User manual

Norton

Norton Assa Abloy D6001DE-L Series User manual

Popular Door Opening System manuals by other brands

AGS

AGS D-PL Instructions for fitting, operating and maintenance

Stanley

Stanley MA900ñ Installation and owner's manual

WITTUR

WITTUR Hydra Plus UD300 Instruction handbook

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

GEZE

GEZE ECturn user manual