80-9380-2211-020 (04-06)

Page 2

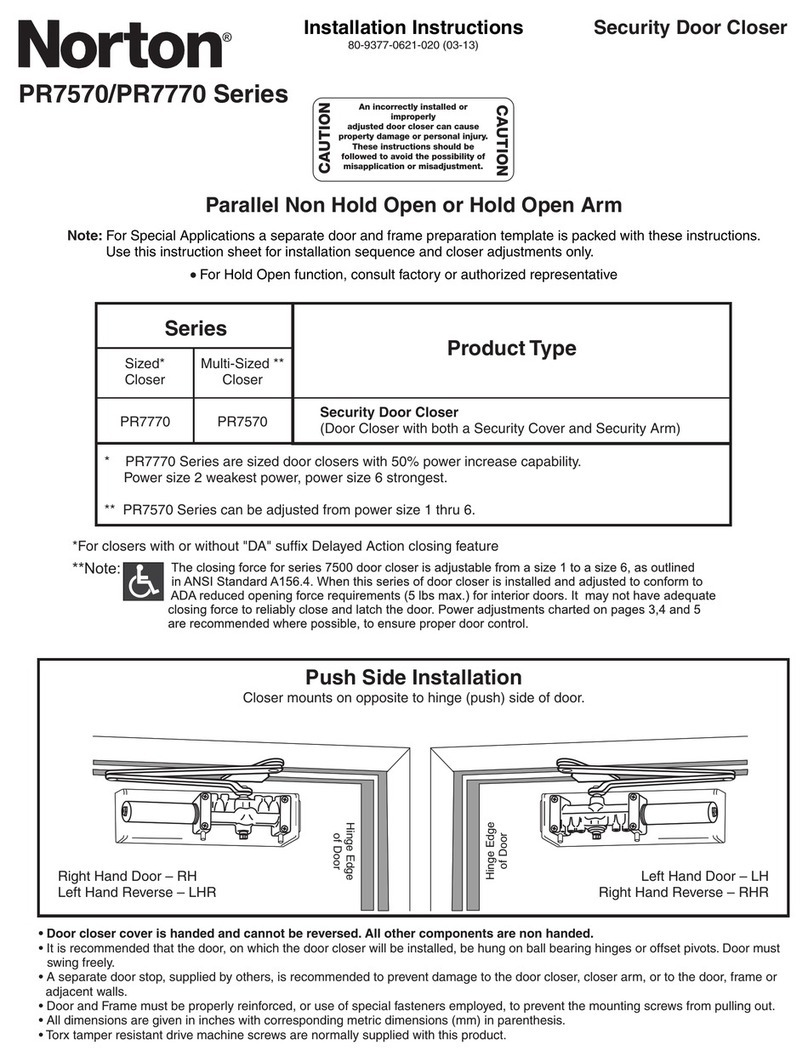

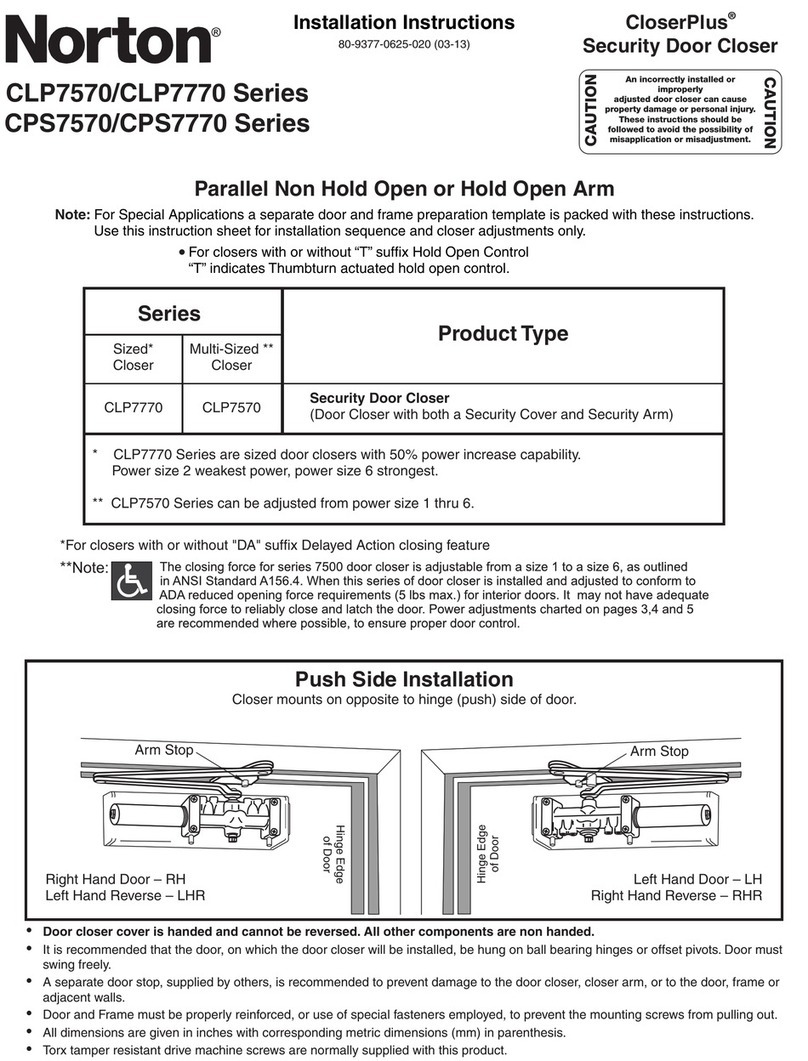

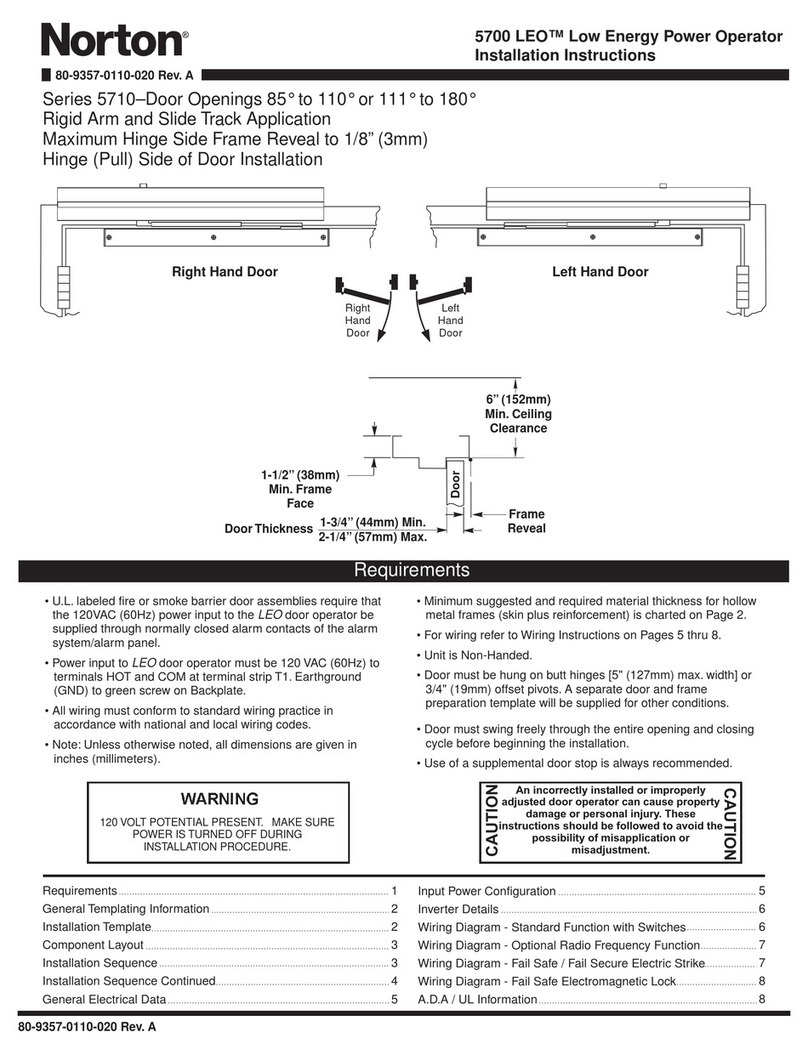

Arm Indexing

Pinion Flat Pinion Flat

RH Door LH Door

7. ith valve end of closer

toward hinge edge of door.

8. and install 9/64" hex drive

socket head screw from screw pack.

9. using Arm Indexing

instructions above.

10.

11. in track assembly. Secure

by pushing in on the retainer clip that extends from the slide

block in the track, until it is flush with the slide block (see

Attaching Arm Stud to Slide on page 4).

(Proceed to pages 5 and 6 for closer adjustments and PT/PTS

wiring)

Mount CLOSER BODY to door

Adjust arm to shortest length

Place slide arm on pinion shaft

Secure arm with arm washer and arm screw.

Insert arm stud into slide block

w

1.

Locate and drill 1-1/8" (29mm) diameter hole in frame face

for the conduit.

2. using above

template:

holes for

holes for . holes for

3. using "Preparation

for Fasteners" chart on page 4.

4. with spring buffer toward

hinge edge of frame and open side facing down.

5. from hook-up box assy.

6. with

conduit hole openings away from hinge edge of frame.

Place Hook-Up Box straps between frame and

chassis. Special conduit nut supplied to anchor 3/4"

conduit fitting.

For Concealed Wire Applications Only:

Locate mounting holes in door and frame

Door – 4 Closer

Frame – 2 Track 2 Hook-up Box

Prepare mounting holes for fasteners

Fasten Track Assembly to frame

Remove metal cover and straps .

Fasten Hook-up Box Straps and Chassis to frame

NOTES:

NOTE: Units with a 120V to 24V transformer require that

hook-up board be removed from chassis to enable

mounting.

5

(127)

1-3/8

(35) 3/4

(19)

1-7/16

(36.5)

12

(304.8)

4 Holes for Closer:

1/4-20 Machine Screw

or 3/8 Dia. Sex-Nuts

2 Holes for Hook-Up Box

8-32 Machine Screw

For Concealed

Wiring Only

1-1/8 (29mm) Hole

For Conduit

1-1/4

(32)

D3-5/8

(92)

19

(482.6)

A

C

B

2 Holes for Track:

1/4-20 Machine Screw

C

LHinge or Pivot

NOTES:

• From centerline of pivot point to end

of track and hook-up box see

dimension “E” in chart

• Right hand door shown

• Do not scale drawing

• Dimensions are given in inches (mm)

• Minimum ceiling clearance for unit is

2-1/8" (54mm)

• Maximum door opening is 110°

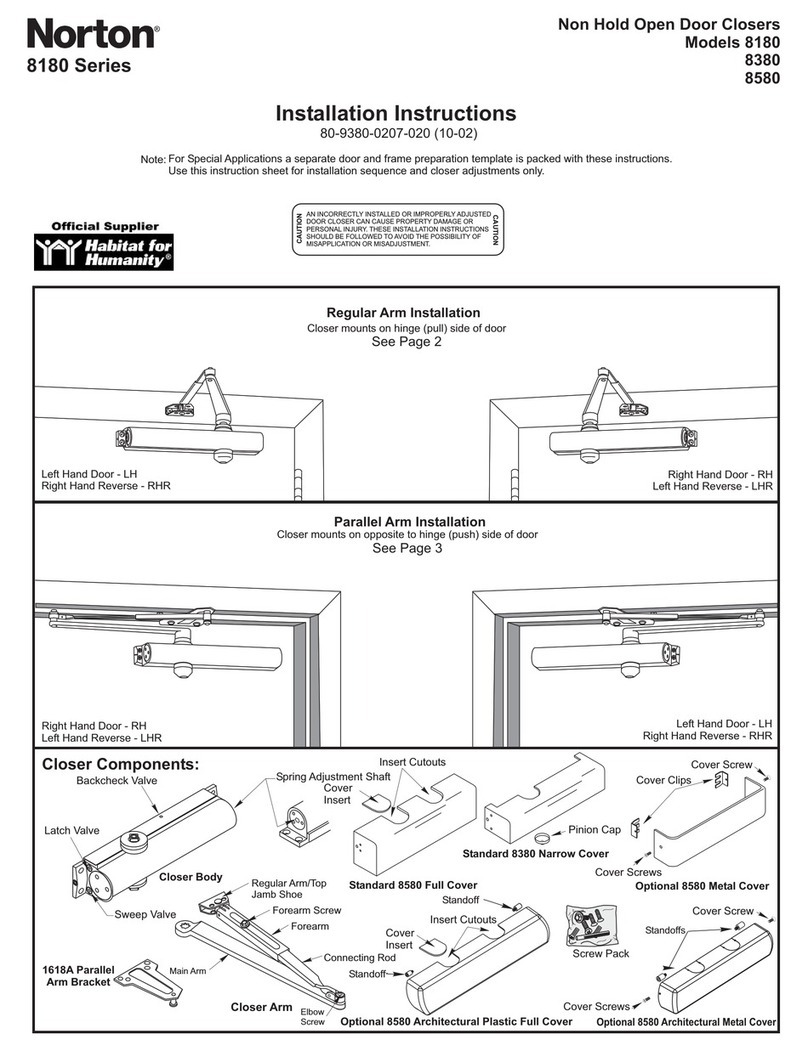

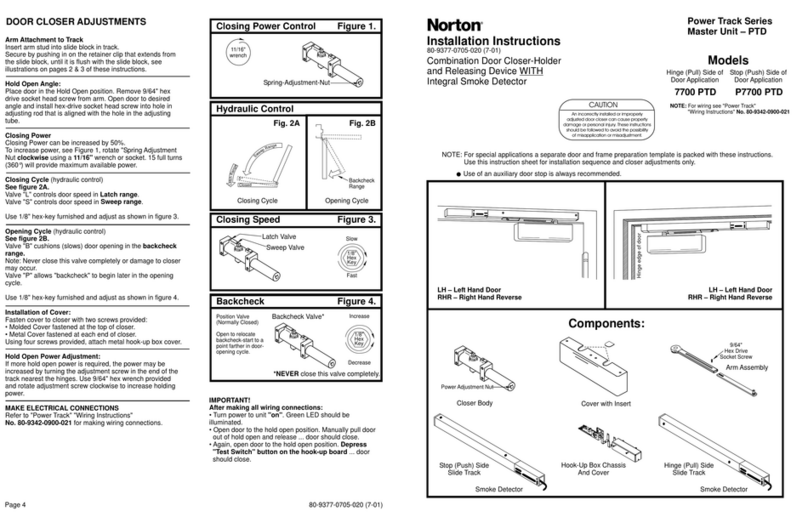

Page 3

Arm Indexing

Pinion Flat Pinion Flat

LH Door RH Door

7.

ith spring adjustment nut toward hinge edge

of door.

8. and install 9/64" hex drive

socket head screw from screw pack.

9. using Arm Indexing

instructions above.

10.

11. in track assembly. Secure

by pushing in on the retainer clip that extends from the slide

block in the track, until it is flush with the slide block (see

Attaching Arm Stud to Slide on page 4).

(Proceed to pages 5 and 6 for closer adjustment and PT/PTS

wiring)

Mount CLOSER BODY (or Drop Plate and then Closer

Body) to door

Adjust arm to shortest length

Place slide arm on pinion shaft

Secure arm with arm washer and arm screw.

Insert arm stud into slide block

w

1.

Locate and drill 1-1/8" (29mm) diameter hole in frame soffit for

the conduit.

2. using above

template:

holes for or

holes for . holes for

3. using "Preparation

for Fasteners" chart on page 4.

4. with spring buffer toward

hinge edge of frame and open side facing down.

5. from hook-up box assy.

6. with

conduit hole openings away from hinge edge of frame.

Place Hook-Up Box straps between frame and

chassis. Special conduit nut supplied to anchor 3/4" conduit

fitting.

For Concealed Wire Applications Only:

Locate mounting holes in door and frame

Door – 4 Closer (8148 Drop Plate, see page 4)

Frame – 3 Track 2 Hook-up Box

Prepare mounting holes for fasteners

Fasten Track Assembly to frame

Remove metal cover and straps .

Fasten Hook-up Box Straps and Chassis to frame

NOTES:

NOTE: Units with a 120V to 24V transformer require that

hook-up board be removed from chassis to enable mounting.

Preparation for Fasteners

Opening

Metal Frame

Metal

Door or Frame

Wood or

Composite

Door

Fasteners

8-32 Machine Screw

1/4-20 Machine Screw

3/8 Dia. Sex Nut

Fastener Preparation

Drill: #29 [.136" (3.45mm) dia.]

8-32 UNC Tap

Drill: #7 [.201" (5.10mm) dia.]

1/4"-20 UNC Tap

3/8" [.375" (9.50mm) dia.]

through

NOTES:

• From centerline of pivot point to end

of track and hook-up box see

dimension “E” in chart

• Left hand door shown

• Do not scale drawing

• Dimensions are given in inches (mm)

• Maximum door opening is 110°

1-1/4

(32)

12

(304.8)

3/4

(19)

3-1/4

(83)

4 Holes for Closer

1/4-20 Machine Screw

or 3/8 Dia. Sex-Nuts

Ref. – Bottom of Frame Stop

1

(25)

5-1/4

(133)

12

(304.8)

C

LHinge or Pivot

19

(482.6)

2 Holes for Hook-Up Box:

8-32 Machine Screw

3 Holes for Track:

1/4-20 Machine Screw

D

C

B

A

For Concealed Wiring Only

1-1/8 (29) Hole for Conduit

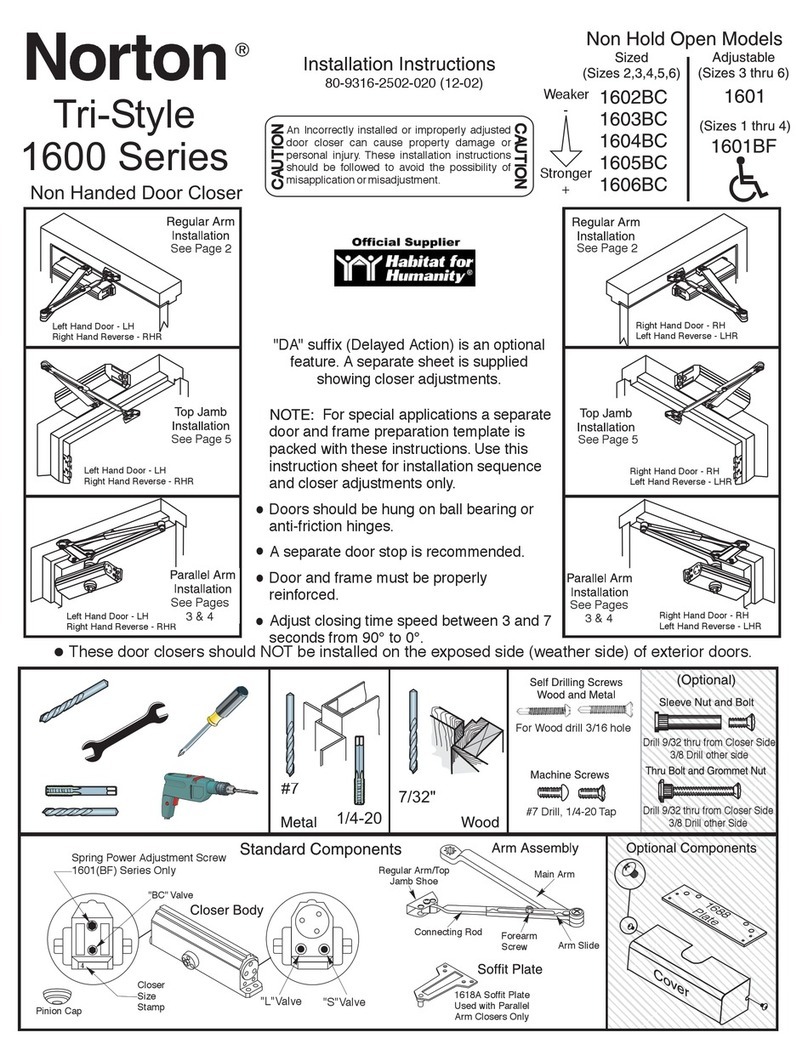

80-9380-2211-020 (04-06) Page 4 80-9380-2211-020 (04-06)

PT/PTS

PTD

A

31-1/16 (789)

34-11/16 (881)

B

8-7/16 (214)

12-1/16 (306)

C

7-5/8 (194)

11-1/4 (286)

D

4-3/8 (111)

8 (203) PT/PTS

PTD

A

32-11/16 (830)

36-5/16 (922)

B

8-7/16 (214)

12-1/16 (306)

C

7-5/8 (194)

11-1/4 (286)

D

4-3/8 (111)

8 (203)

Hinge (Pull) Side Applications Stop (Push) Side Applications 8148 Drop Plate Template with Stop (Push) Side Application

Attaching Arm Stud to Slide

Retainer Clip

2

1

Attaching Arm Stud to Slide

NOTES:

• From centerline of pivot point to end

of track and hook-up box see

dimension “E” in chart

• Left hand door shown

• Do not scale drawing

• Dimensions are given in inches (mm)

• Maximum door opening is 110°

4

(101.6)

4

(101.6)

5/16

(7.9)

1-1/2

(38)

4 Holes for Drop Plate

1/4-20 Machine Screw

or 3/8 Dia. Sex-Nuts

Ref. – Bottom of Frame Stop

1

(25)

5-1/4

(133)

12

(304.8)

C

LHinge or Pivot

19

(482.6)

2 Holes for Hook-Up Box:

8-32 Machine Screw

3 Holes for Track:

1/4-20 Machine Screw

D

C

B

A

For Concealed Wiring Only

1-1/8 (29) Hole for Conduit

PT/PTS

PTD

A

32-11/16 (830)

36-5/16 (922)

B

8-7/16 (214)

12-1/16 (306)

C

7-5/8 (194)

11-1/4 (286)

D

4-3/8 (111)

8 (203)

E

32-3/16 (818)

35-13/16 (910)

E

33-13/16 (858)

37-7/16 (951)

E

33-13/16 (858)

37-7/16 (951)