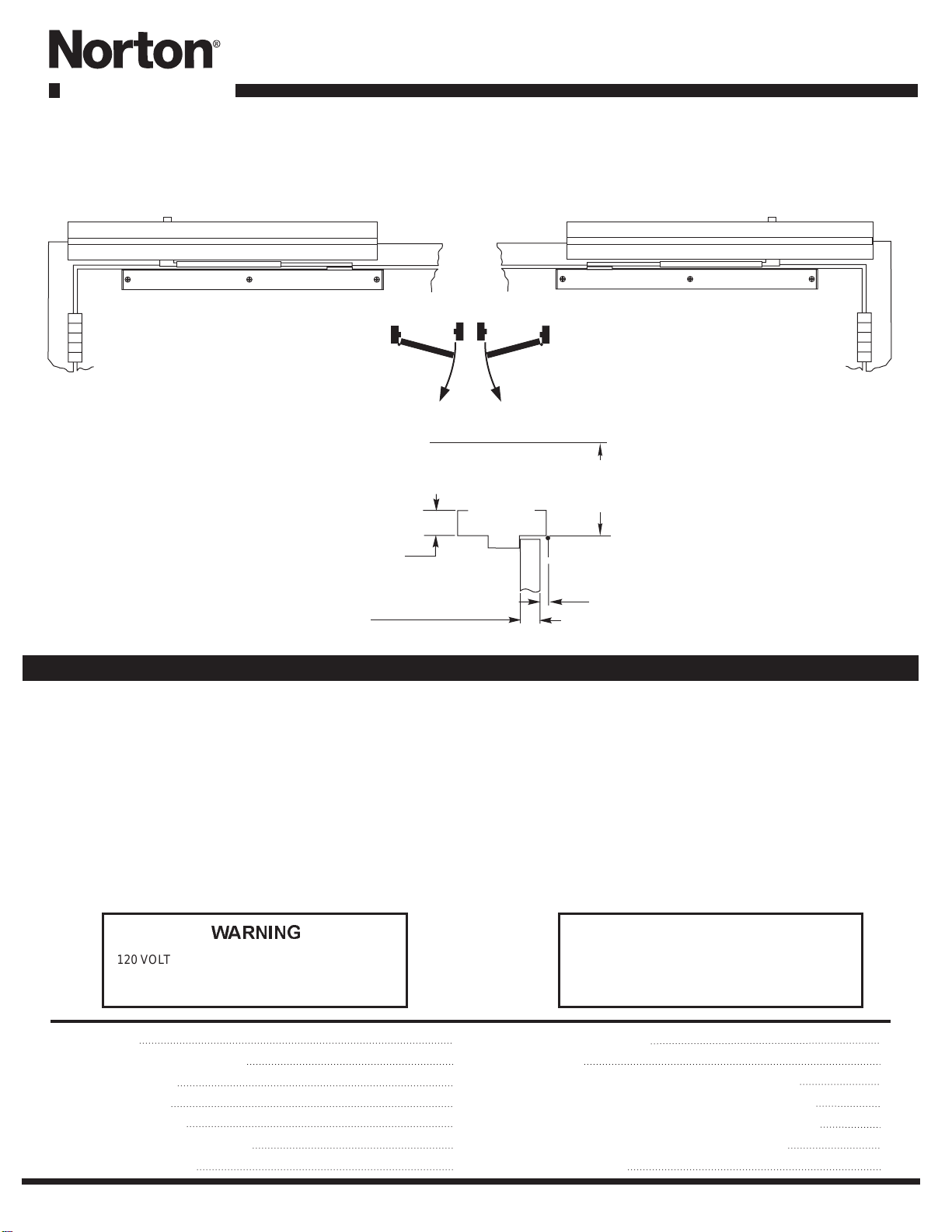

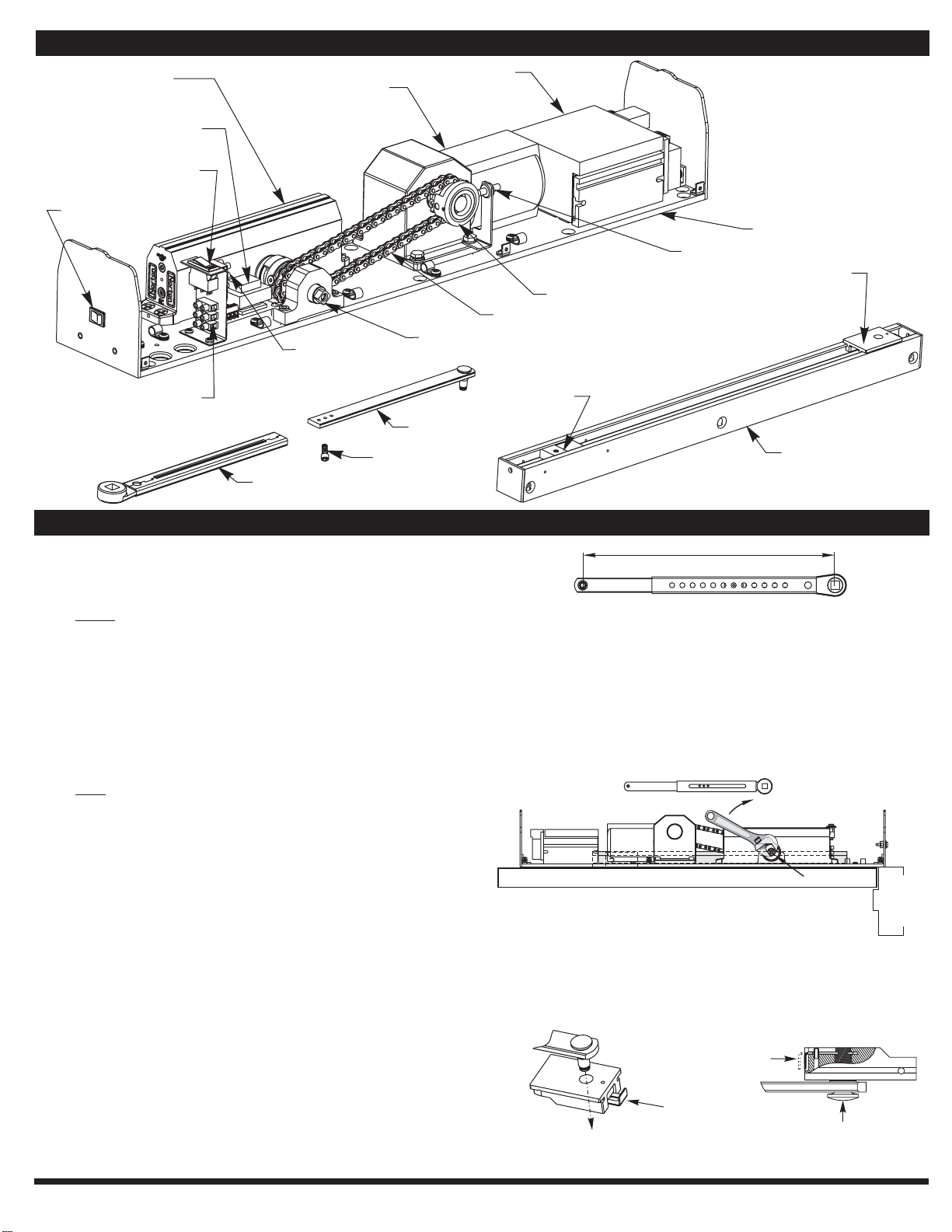

Step 9:

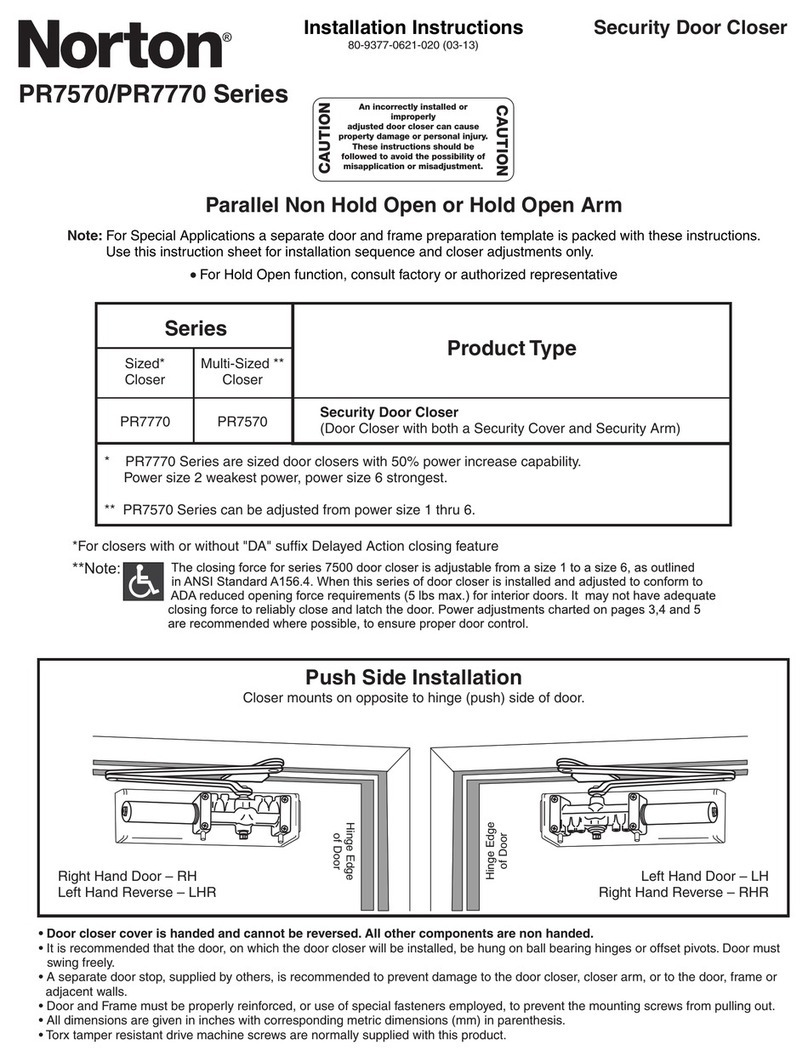

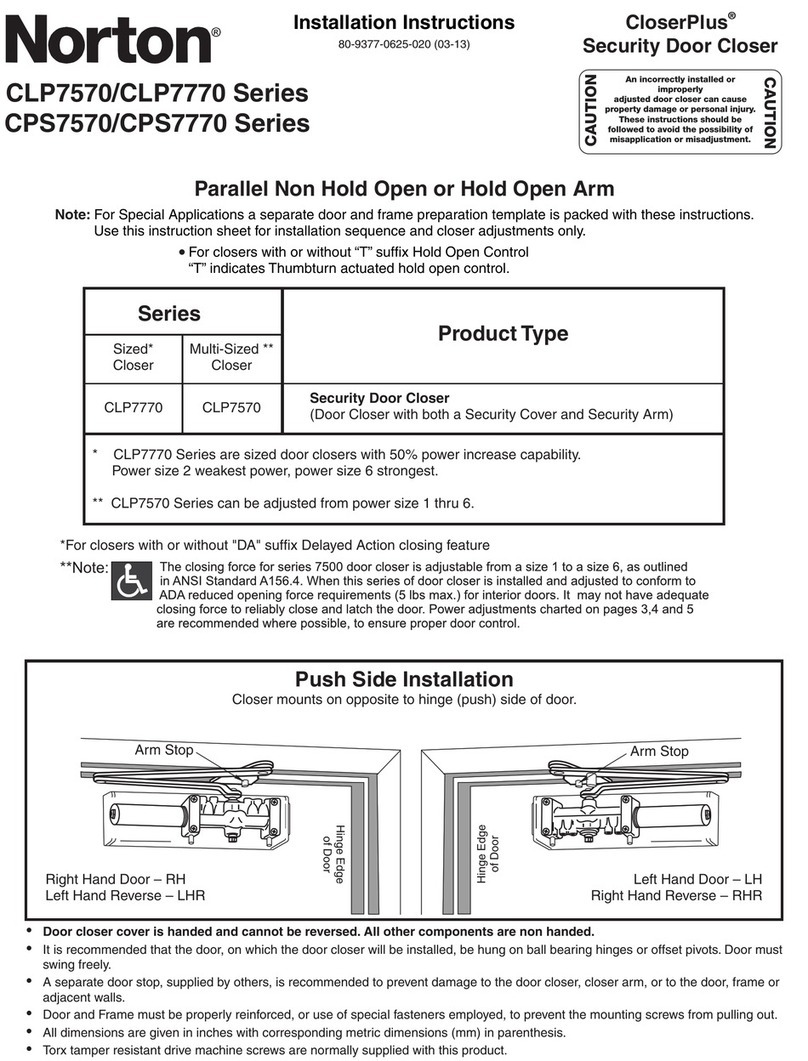

to increase door closing power. Door control is shipped

set at midpoint of power setting.Maximum closing

power can be achieved with 8 (360°) clockwise turns of

the power adjustment screw.

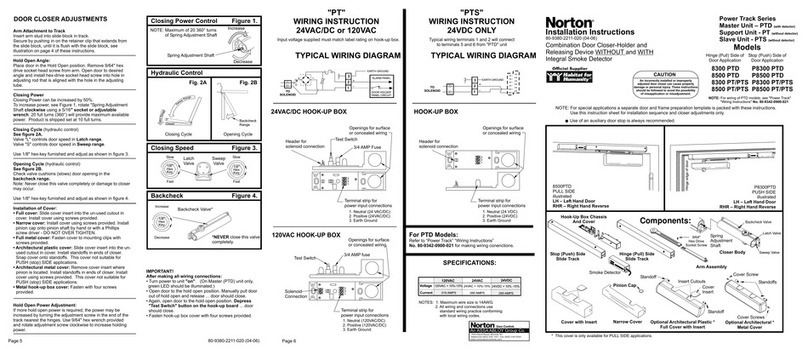

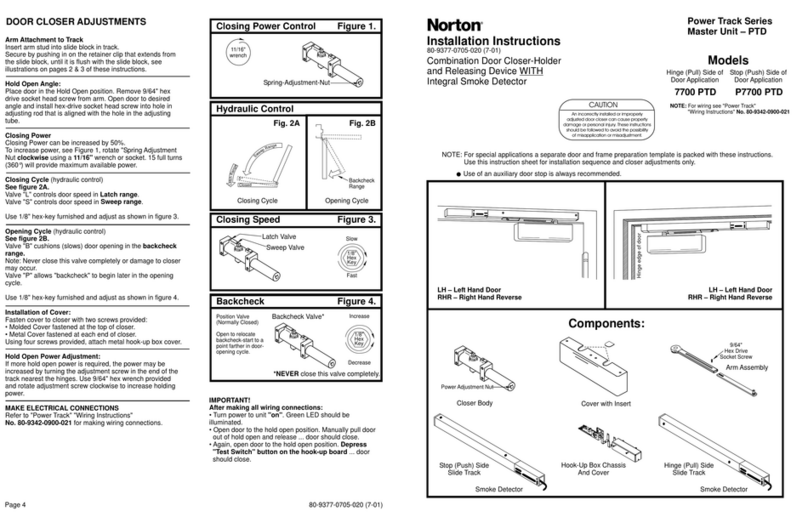

Adjust closing power of unit (See Fig.3) - Using a 1/8”

allen wrench, turn the power adjustment shaft clockwise

Adjust Hydraulic valves using a 1/8” hex wrench to

obtain proper door closing speeds. See following

Step 10:

Step 13:

Step 13:

OFF

Step 14:

Step 15:

Step 16:

Step 17:

Step 18:

Step 19:

Step 20:

Step 21:

Step 22:

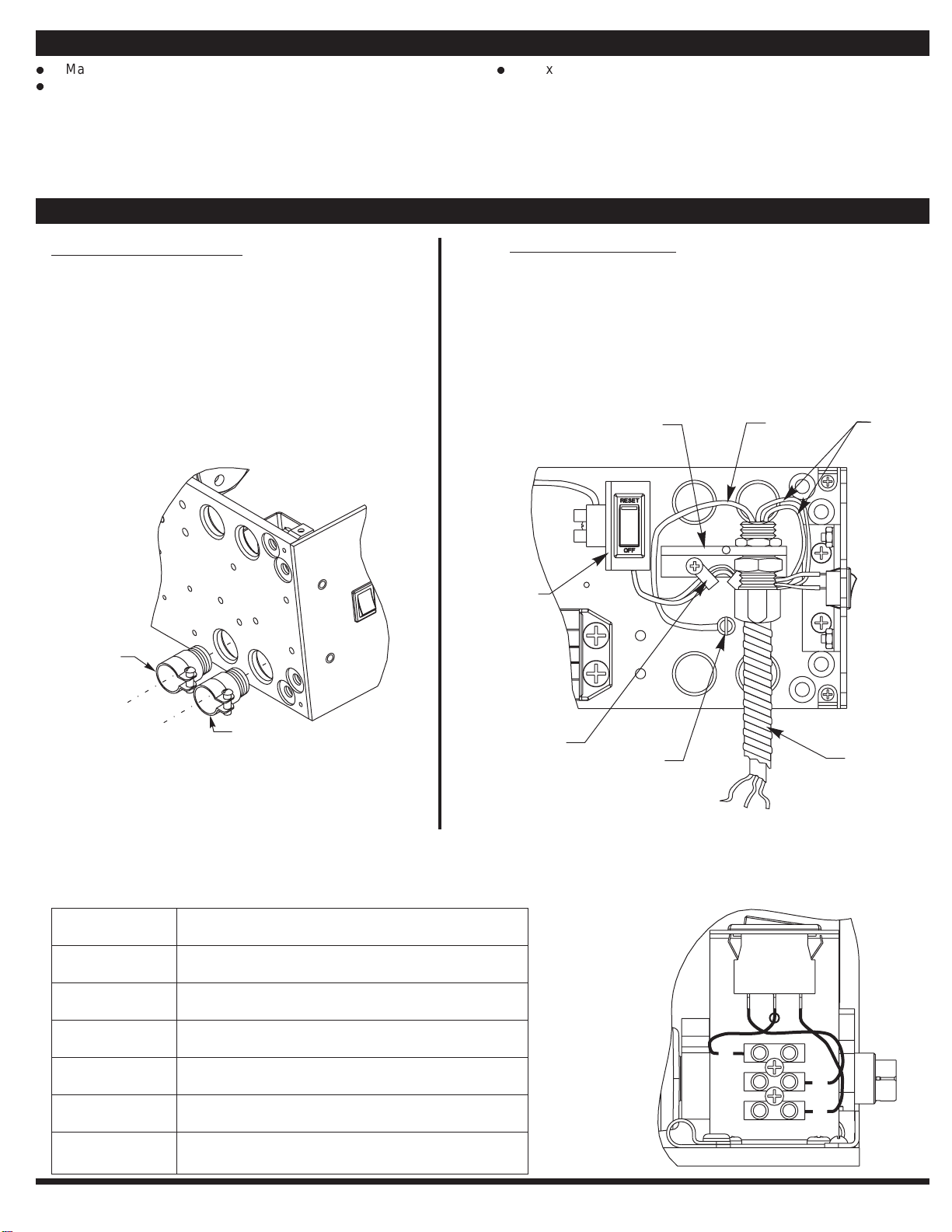

Turn power to unit on at the Unit Power Switch and turn the

Breaker Switch to “RESET”.

Using a short jumper cable, jump terminals 1 and 2, see Fig.

6 below, to activate unit. When door reaches 20 , switch

Breaker Switch to “ ” position cutting power to the unit.

Allow door to fully close (door may be manually pulled

closed).

Once door has fully closed, manually open door slightly and

insert a 1/8” allen wrench (provided with screw pack) into the

clutch assembly as shown below to create a small gap

between the two clutch components.

Manually close door and remove allen wrench from clutch

assembly.

Adjust Closing Ring Position (See Fig.8) - Loosen 8-32 set

screw located on Close Position Ring with 5/64” hex wrench

provided. Rotate Assembly until Closed Position Magnet

aligns with Reed Switch.

Adjust Open Ring Position - Loosen 8-32 set screw located

on Open Position Ring with 5/64” hex wrench provided.

Rotate Ring Assembly until Open Position Magnet is

approximately 180° from Closed Position Magnet.

Flip Breaker Switch to “RESET” to turn power on. Jump

terminals 1 and 2 (as shown in Step 13) to activate door.

Note open position of the door. Allow door to close.

Loosen and readjust Open Position Ring as necessary to

obtain desired door open position. Tighten set screw.

Make all connections necessary for any accessories to the

4-position Accessory Terminal (see Pages 6 - 8).

Make necessary adjustments to inverter (see Page 6).

Replace cover and cover screws.

°

Installation Sequence Continued

Power Adjustment

1/8"

Hex

Key

Increase

Power

Decrease

Power

80-9357-0110-020 Rev. A

4

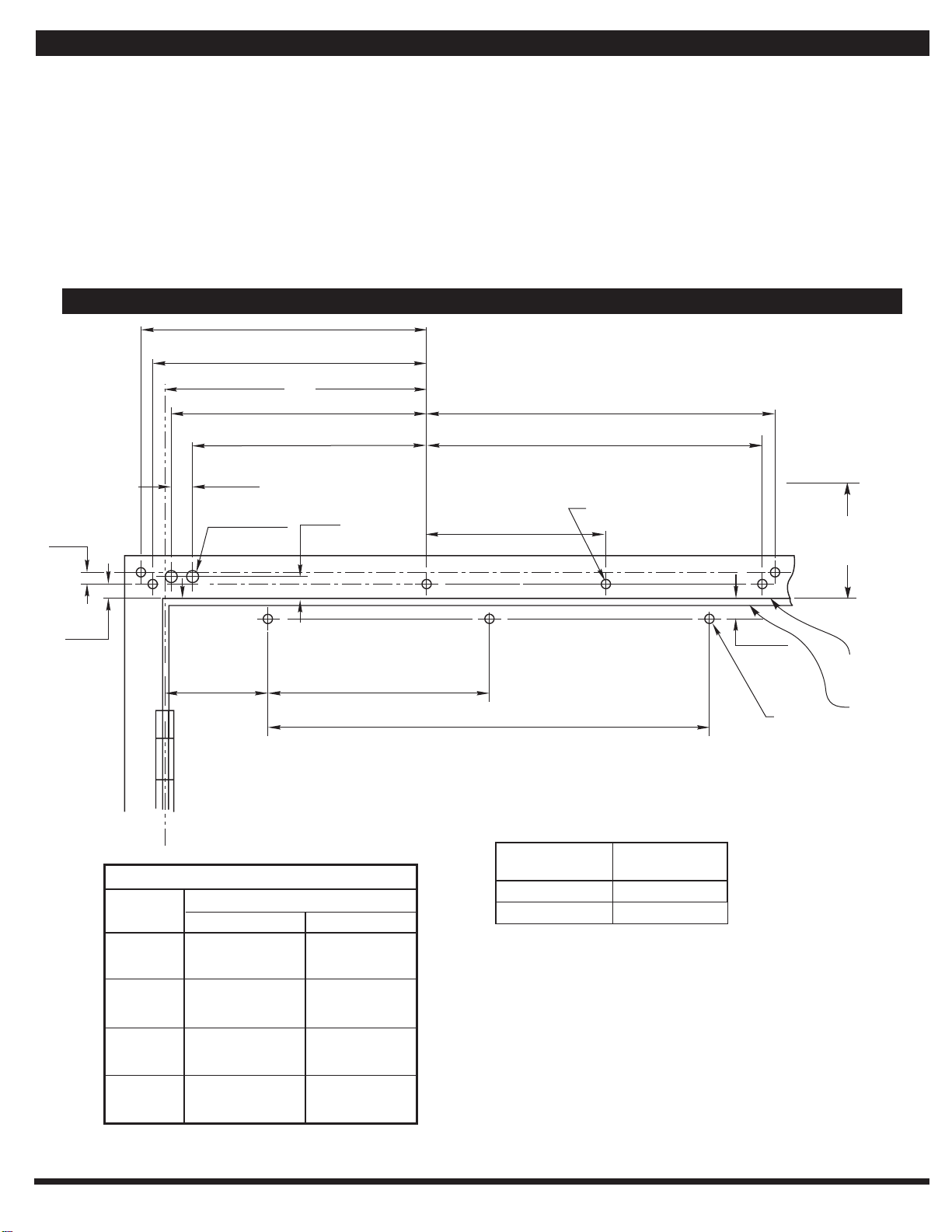

Closing Cycle – Make adjustments, as necessary, to the Sweep

Speed "S" valve and Latch Speed "L" valve. See Fig. 4 below for

location of valves.Turn valves clockwise to reduce speed, counter

clockwise to increase speed.

1/8"

Hex

Key

Slower

Closing

Faster

Closing Closing Cycle

Closed

10°

L

a

t

c

h

R

a

n

g

e

S

w

e

e

p

R

a

n

g

e

Opening Cycle – Adjust Backcheck, "B" valve, as necessary, for

hydraulic resistance to door opening in the backcheck range. See

illustrationinFig.4atbottomofthispageforlocationofvalve.

1/8"

Hex

Key

Increase

Cushion

Decrease

Cushion

Opening Cycle

B

a

c

k

c

h

e

c

k

O

p

e

n

i

n

g

NOTE:ToomuchBackcheck,"B"valve,canaffect heoperation

of the units pump, preventing units from fully opening the

door. This valve may require fine tuning after all other

adjustmentshavebeenmade.

t

Note: A.D.A. requires that from an open position of

70°, the door will take at least 3 seconds to move to

a point 3”(75mm) from the latched position

measured at the leading edge of the door.

Step 11:

,

Make wiring connections using Wiring Instructions

on Page 5.

Step 12:Turn on facility’s main circuit breaker.

Figure 3

Sweep Valve

Latch Valve

Backcheck

Valve

Figure 4

Breaker

Switch

Unit Power Switch

Figure 5

1

2

3

4

1

2

3

4

Figure 6

1/8” Allen Wrench

Clutch Assembly

Figure 7

Reed Switch

Closing Position

Magnet

Closing Position

Adjustment

Opening Position

Magnet

Opening Position

Adjustment

Figure 8