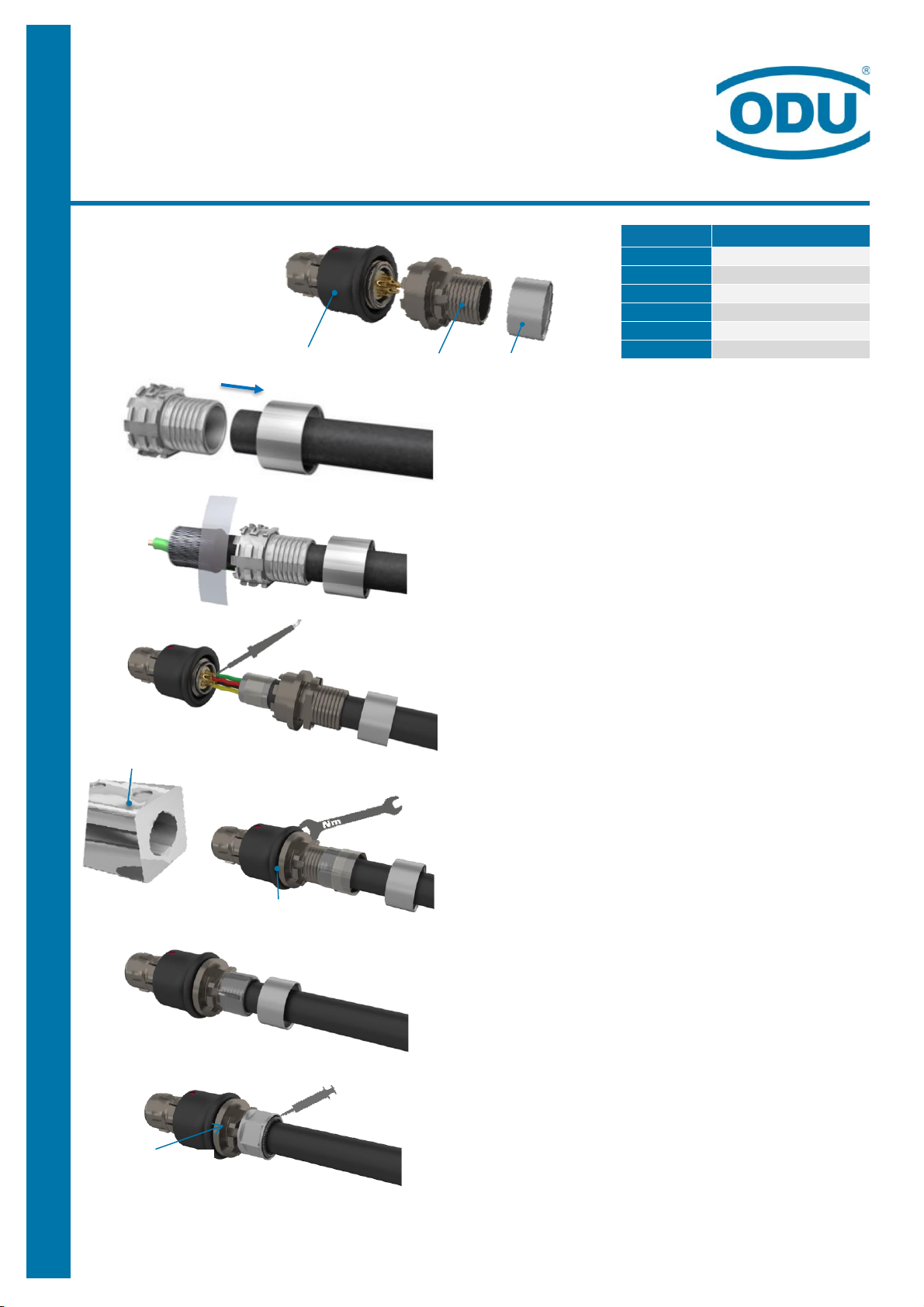

1. Slide crimp sleeve and crimp adapter over the

cable. The crimp sleeve is not needed if a metal

band is used for fastening the shield to the crimp

adapter.

2. Strip the cable and conductors (page 2). Fold

back the shield and use fastening tape to fasten

it temporarily to the cable jacket. Tin-plate this

wires if needed.

3. Solder the wires, noting the placement of each

wire according to your wiring chart. Clean the

solder area with Isopropylalcohol and brush.

4. Screw the crimp adapter on so that it is flush,

observing torque values. Secure the screw

thread with adhesive. The assembly tools

should be used to counter the torque.(see page 3)

5. Remove the fastening tape and lay the shield

braid on to the crimp adapter.

6. Fasten the shield braid to the crimp adapter by

means of crimping or by using a metal band.

More information.(see page 4) Pour potting

compound into the connection area

7. Bend relief: This can be implemented by means

of overmolding or by using shrink boot.

More information. (see page 5)