Page 7

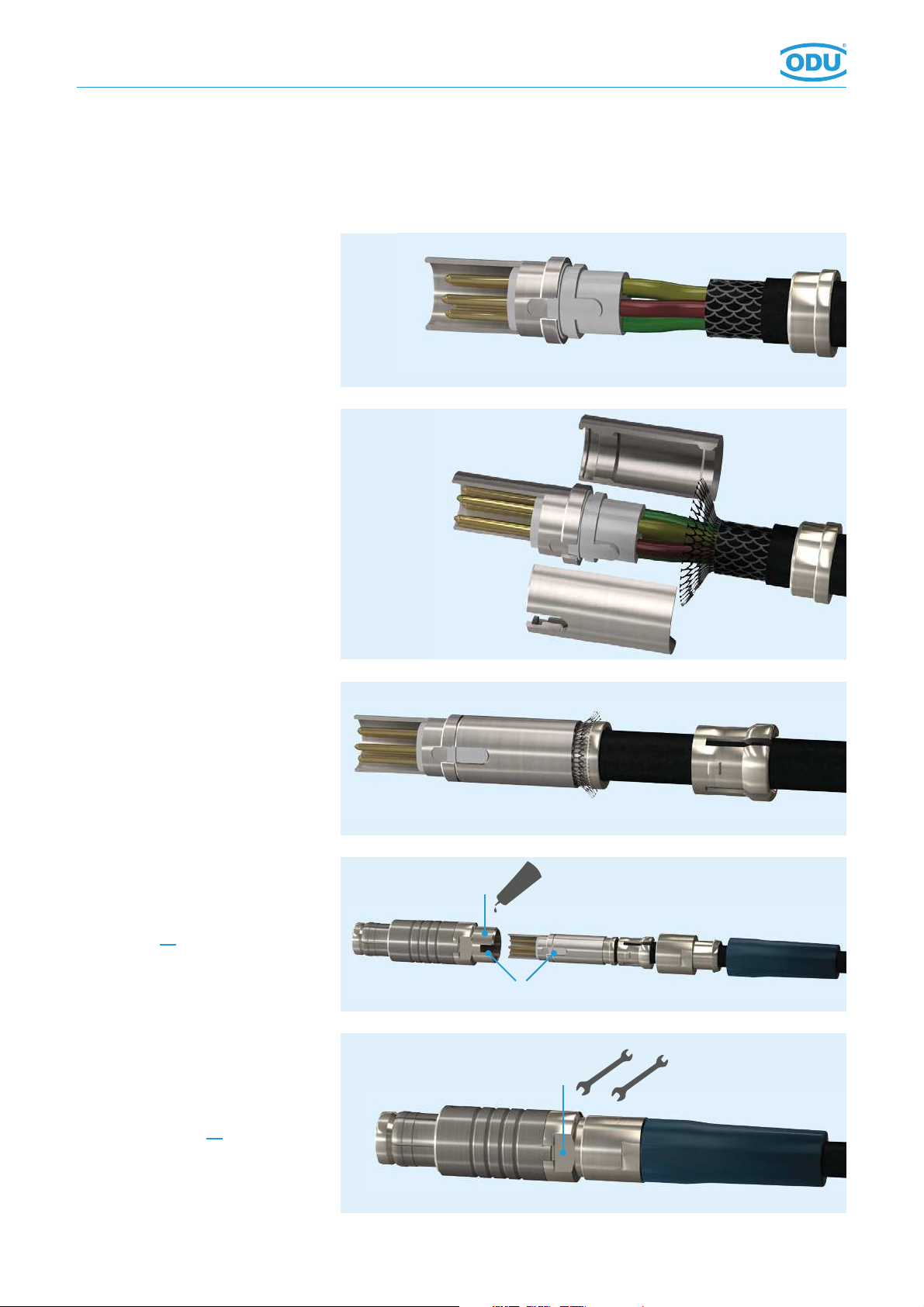

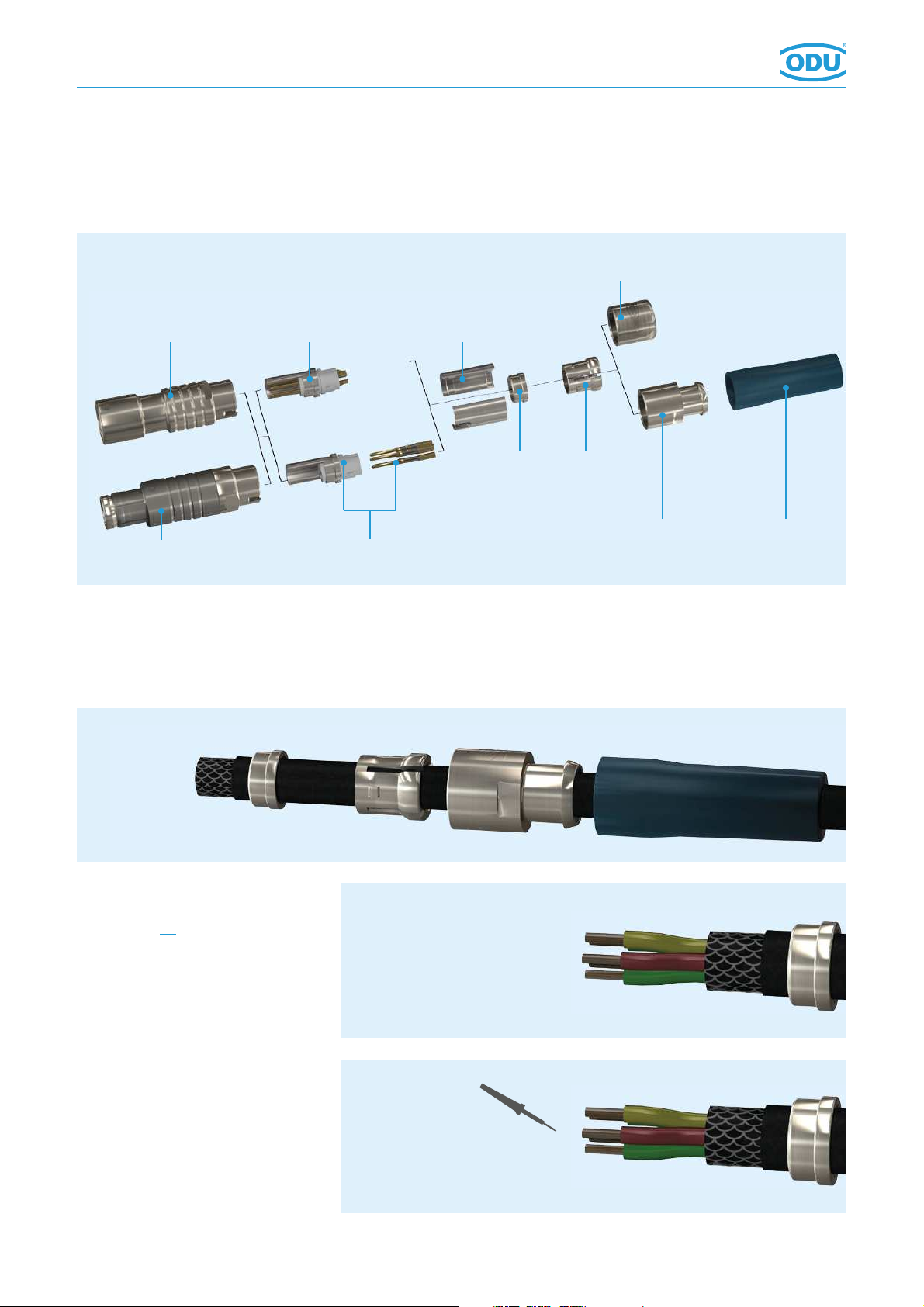

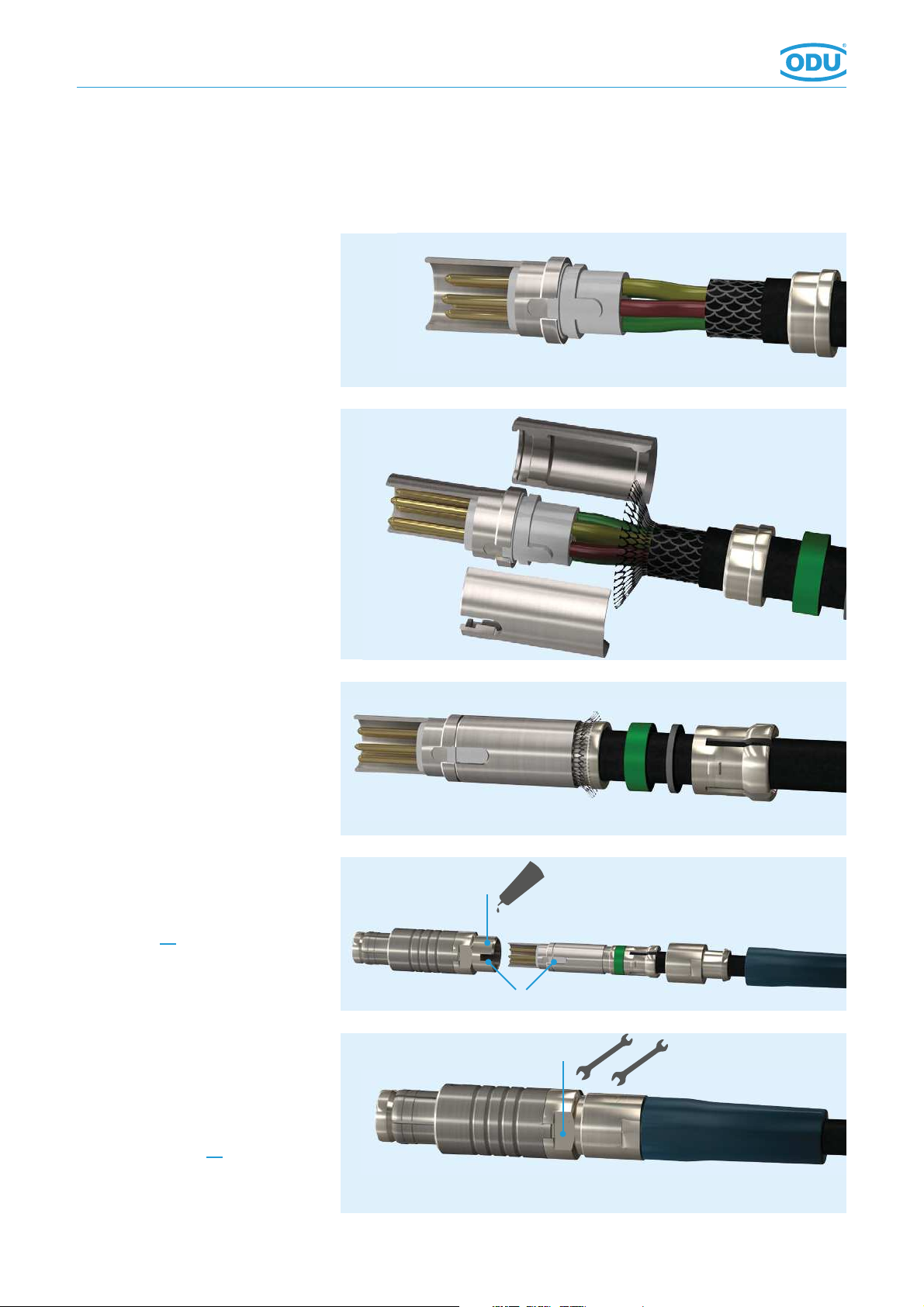

4. Insert contacts into insulator

according to contact arrangement.

5. Bend cable shield outwards,

assemble half shells.

6. Slide the EMI ring, sealing, washer

and the cable collet against the

half-shells and clamp the shield

against it.

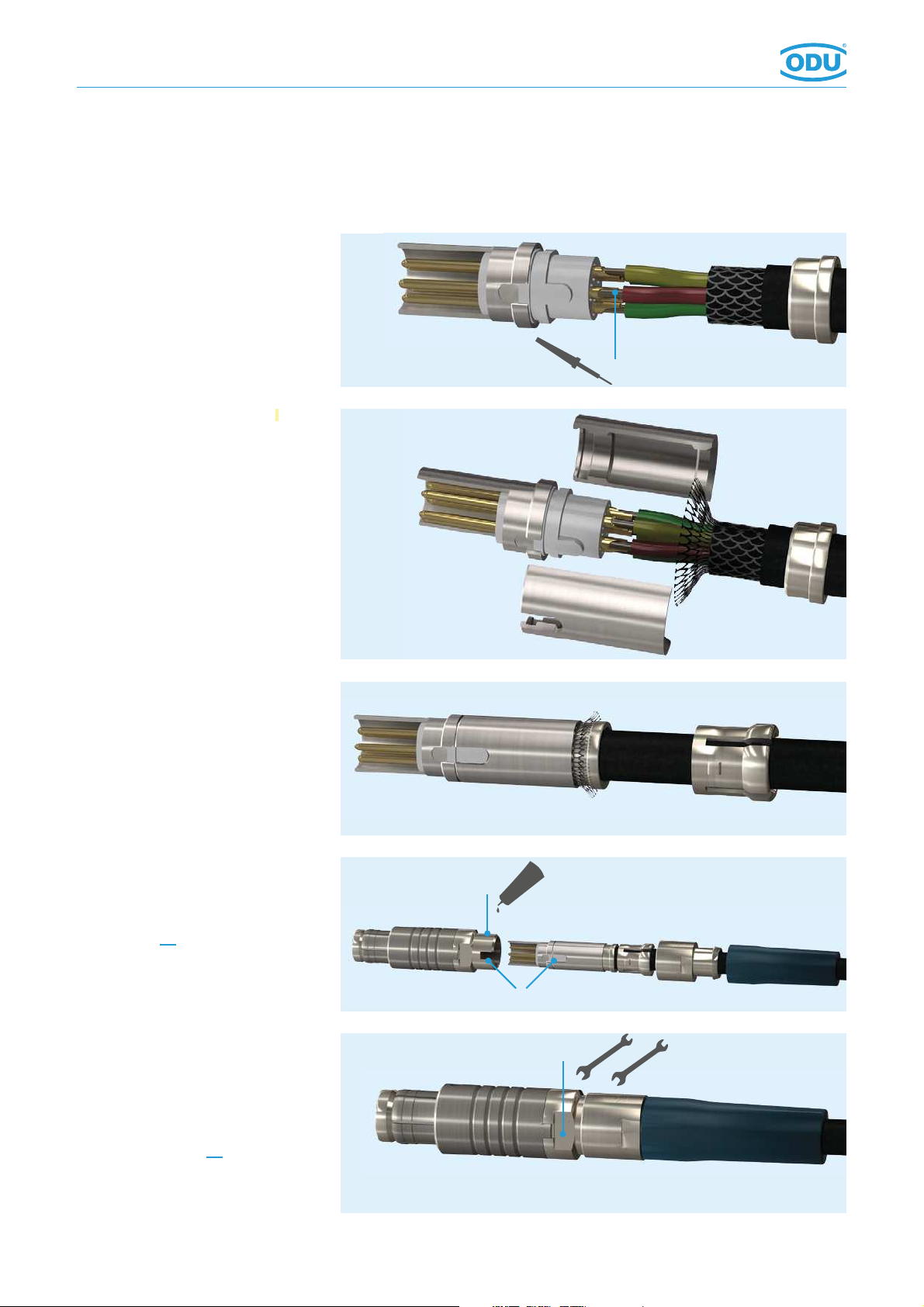

7. Put the assembled cable

considering the guidings (B) in the

connector housing. If necessary,

secure thread (A) with adhesive

(see page 18).

8. Screw back nut on the assembled

plug, counterhold by means of the

spanner at (C) and hold against

with ODU spanner wrench.

Caution! Consider tightening

torque (see page 18).

The assembly is nished.

010.055.000.000.000

Assembly Instructions