1

INDEX

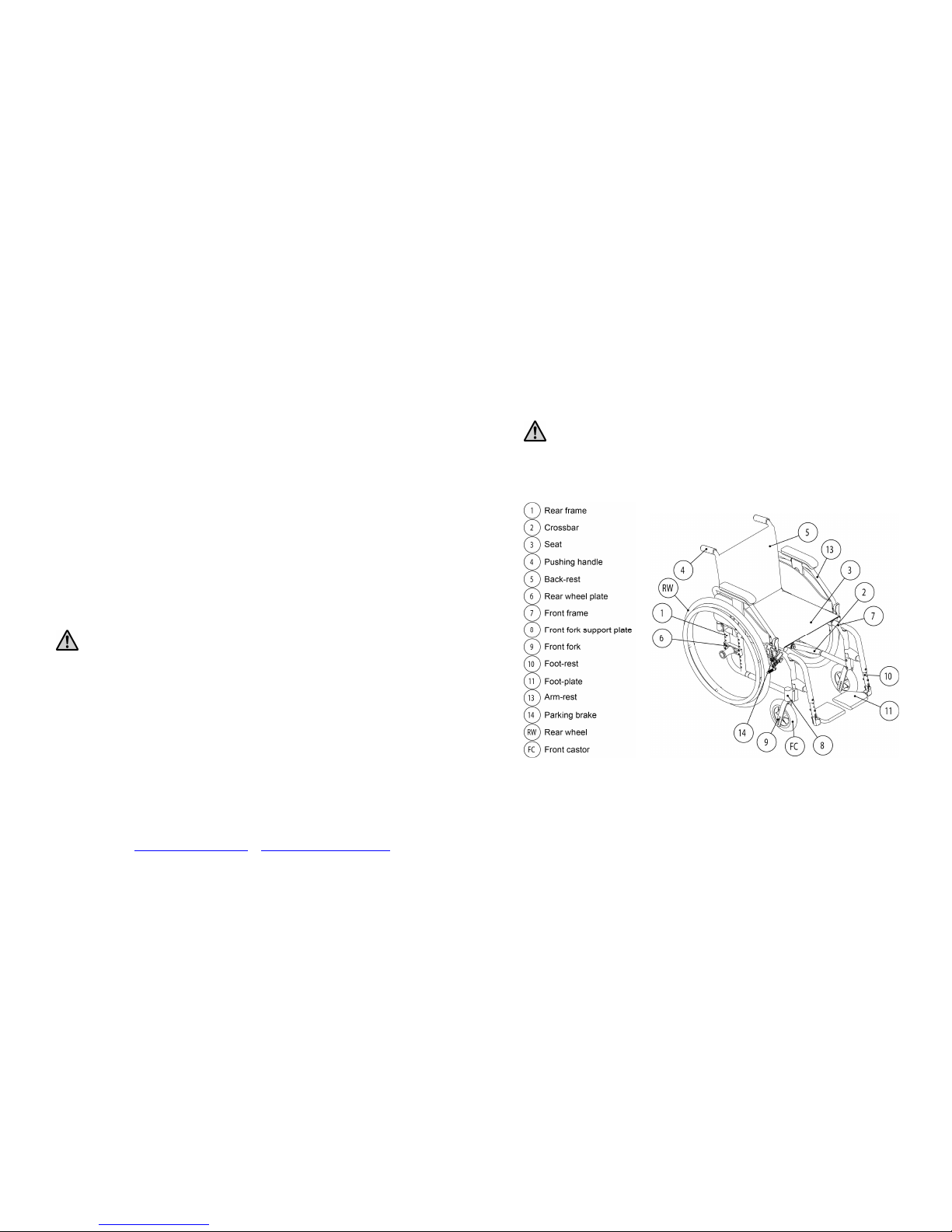

1. INTRODUCTION .........................................................................................4

1.1 D

ESCRIPTION

.........................................................................................4

1.2 F

EATURES

..............................................................................................6

2. PREPARATION FOR USE..........................................................................6

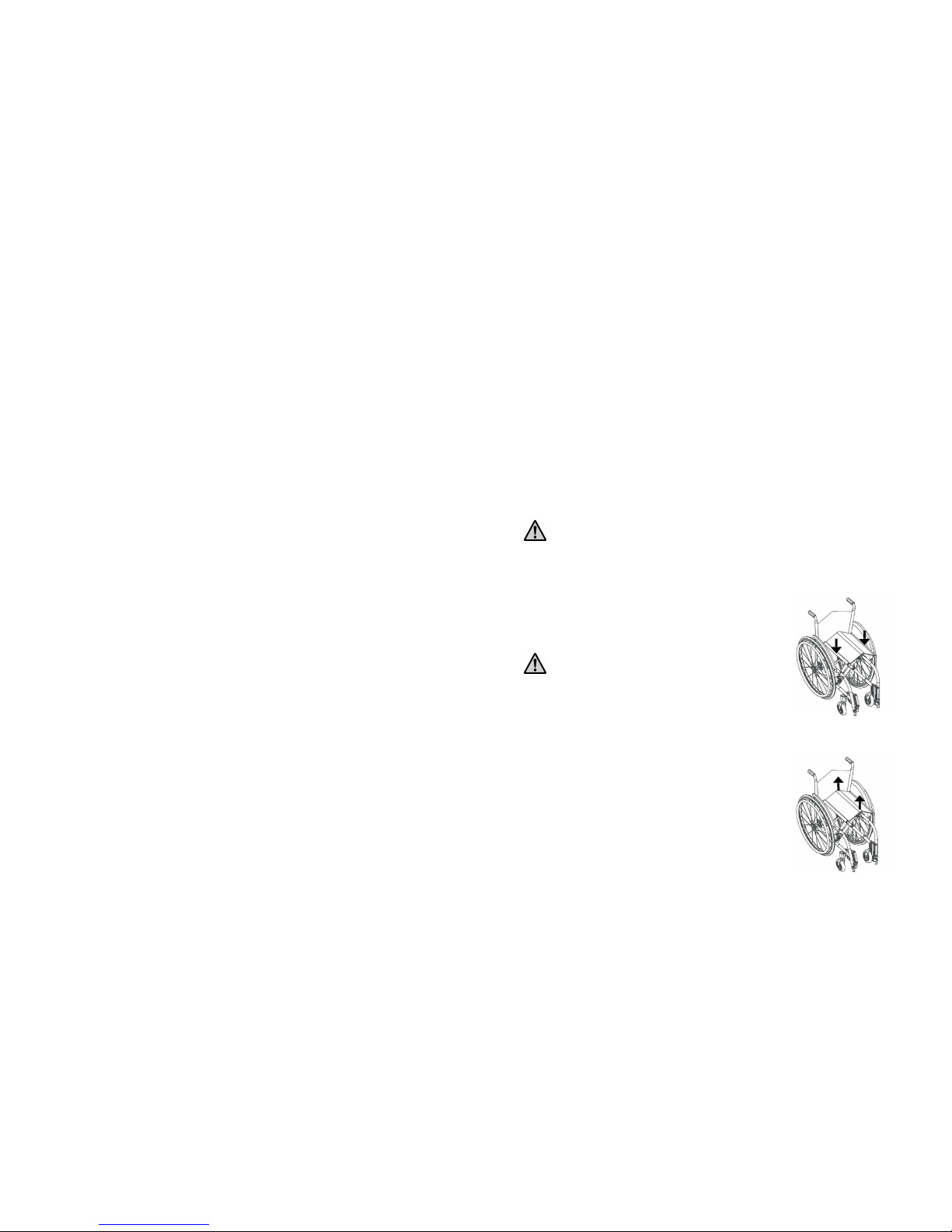

2.1 W

HEELCHAIR OPENING

..........................................................................6

2.2 W

HEELCHAIR FOLDING

..........................................................................6

2.3 T

YRE PRESSURE CHECK

..........................................................................7

2.4 R

EAR WHEELS ASSEMBLY CHECK

...........................................................7

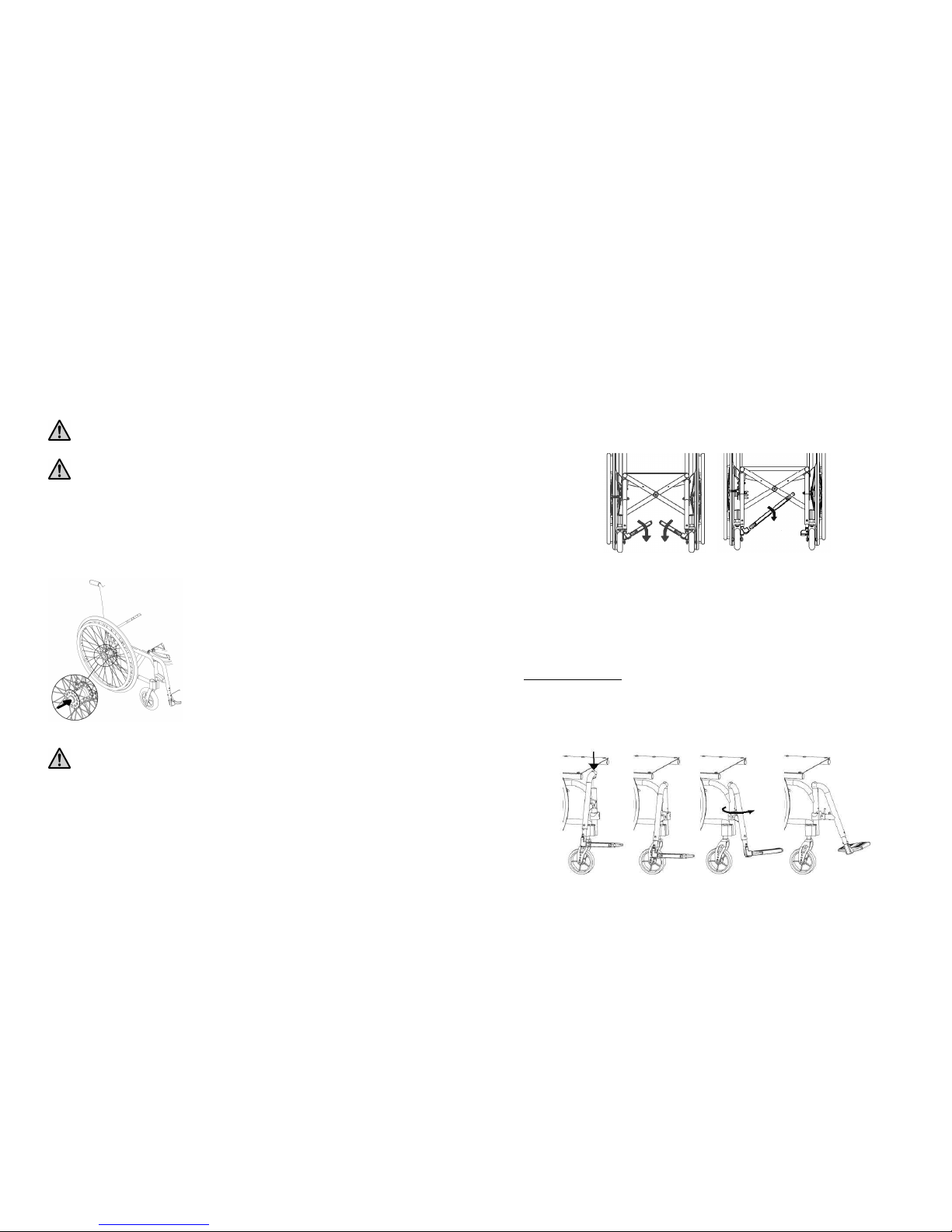

2.5 F

OOT

-

REST POSITIONING

........................................................................8

2.6 B

RAKES CHECK

......................................................................................9

2.7 A

CCESSORIES CHECK

.............................................................................9

3. SETTING UP ...............................................................................................10

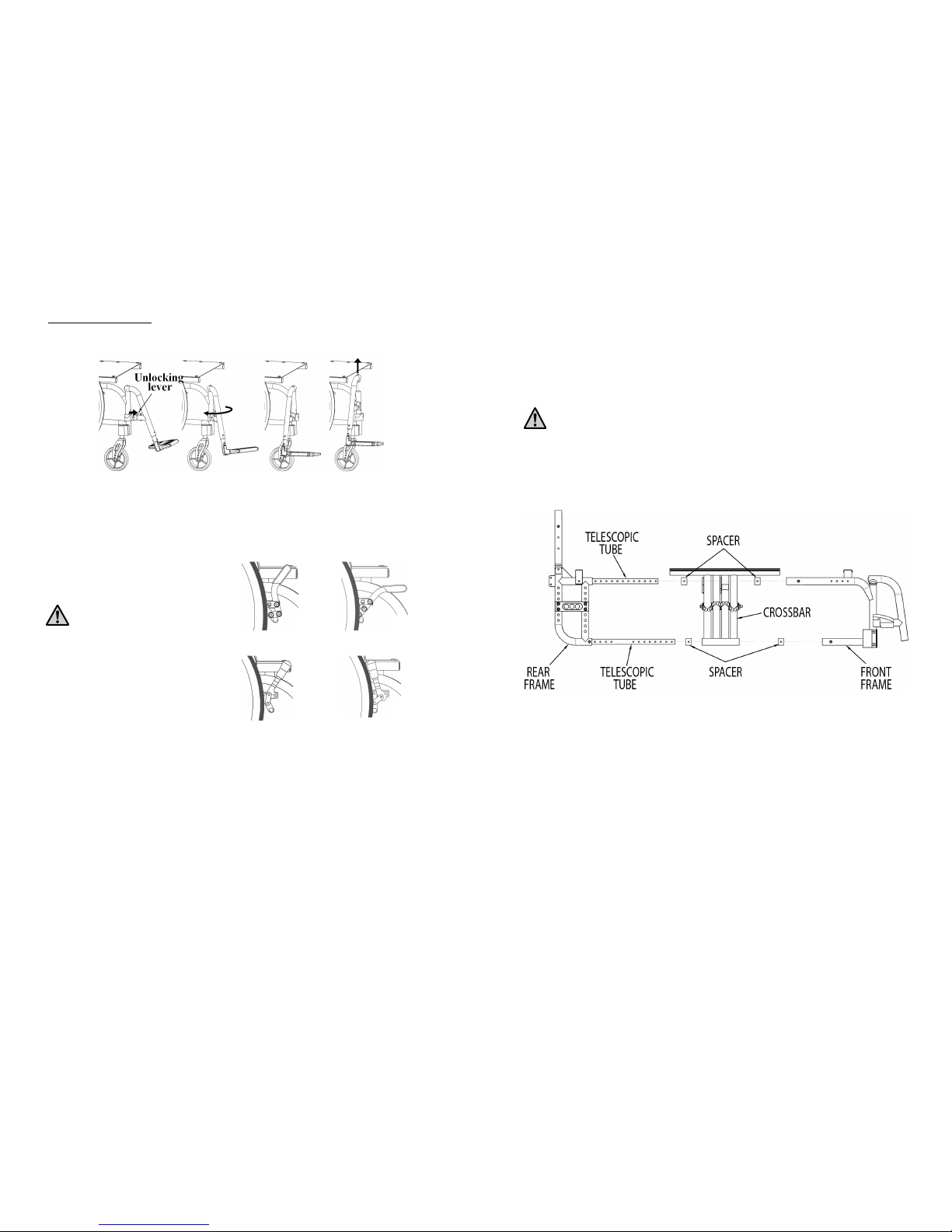

3.1 F

RAME DEPTH ADJUSTMENT

.................................................................10

3.2 R

EAR SEAT HEIGHT ADJUSTMENT

.........................................................13

3.3 G

RAVITY CENTRE ADJUSTMENT

...........................................................13

3.4 F

RONT SEAT HEIGHT ADJUSTMENT

.......................................................14

3.5 F

RONT FORK SUPPORT PLATE ADJUSTMENT

.........................................14

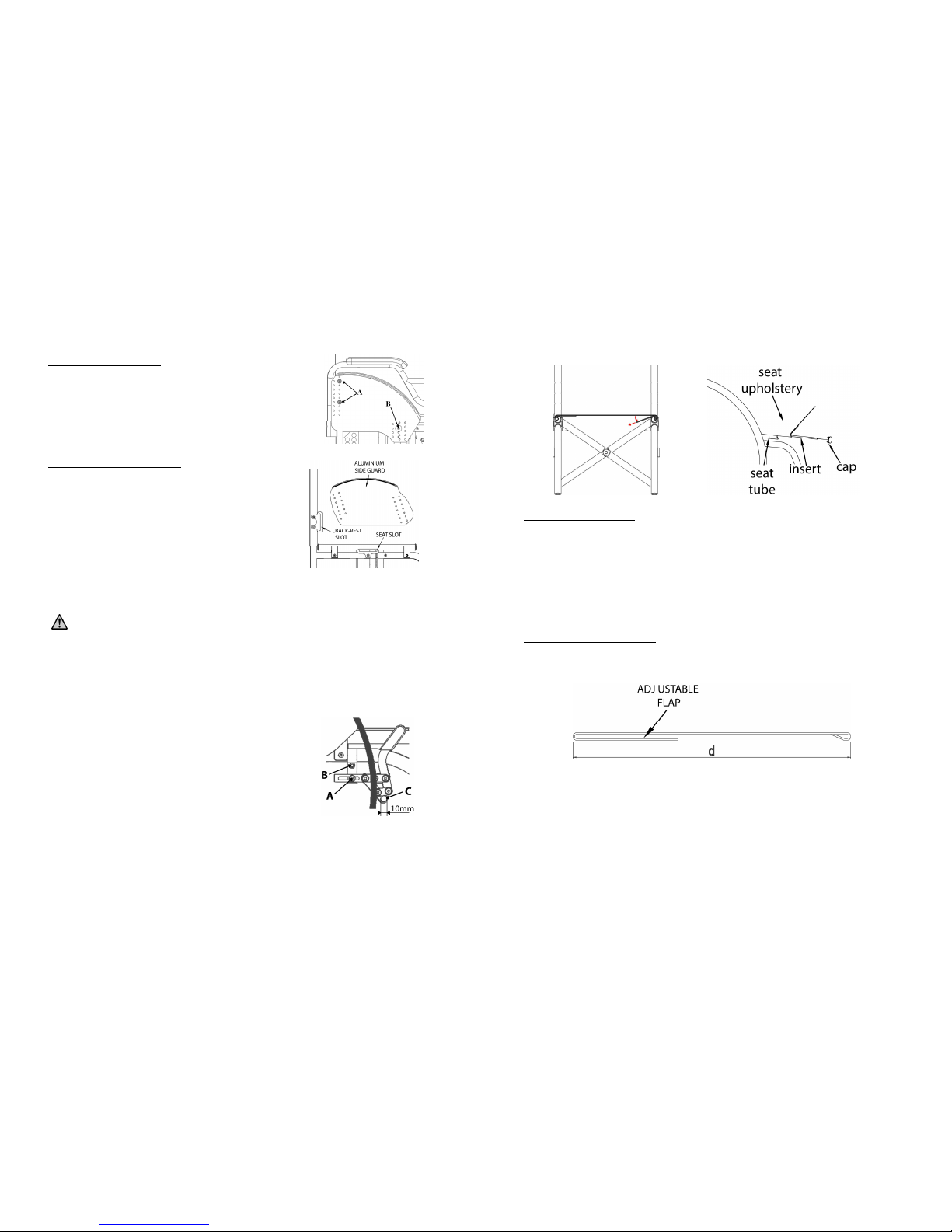

3.6 S

IDE GUARD ADJUSTMENT

...................................................................15

3.7 B

RAKES ADJUSTMENT AND MAINTENANCE

..........................................15

3.8 S

EAT UPHOLSTERY ADJUSTMENT AN REPLACEMENT

............................16

3.9 B

ACK

-

REST TENSION ADJUSTMENT

......................................................17

3.10 B

ACK

-

REST HEIGHT ADJUSTMENT

........................................................17

3.11 H

EIGHT ADJUSTABLE PUSHING HANDLES

.............................................17

3.12 F

OOT

-

PLATE TO SEAT DISTANCE ADJUSTMENT

.....................................18

3.13 F

OOT

-

PLATE TILT ADJUSTMENT

...........................................................18

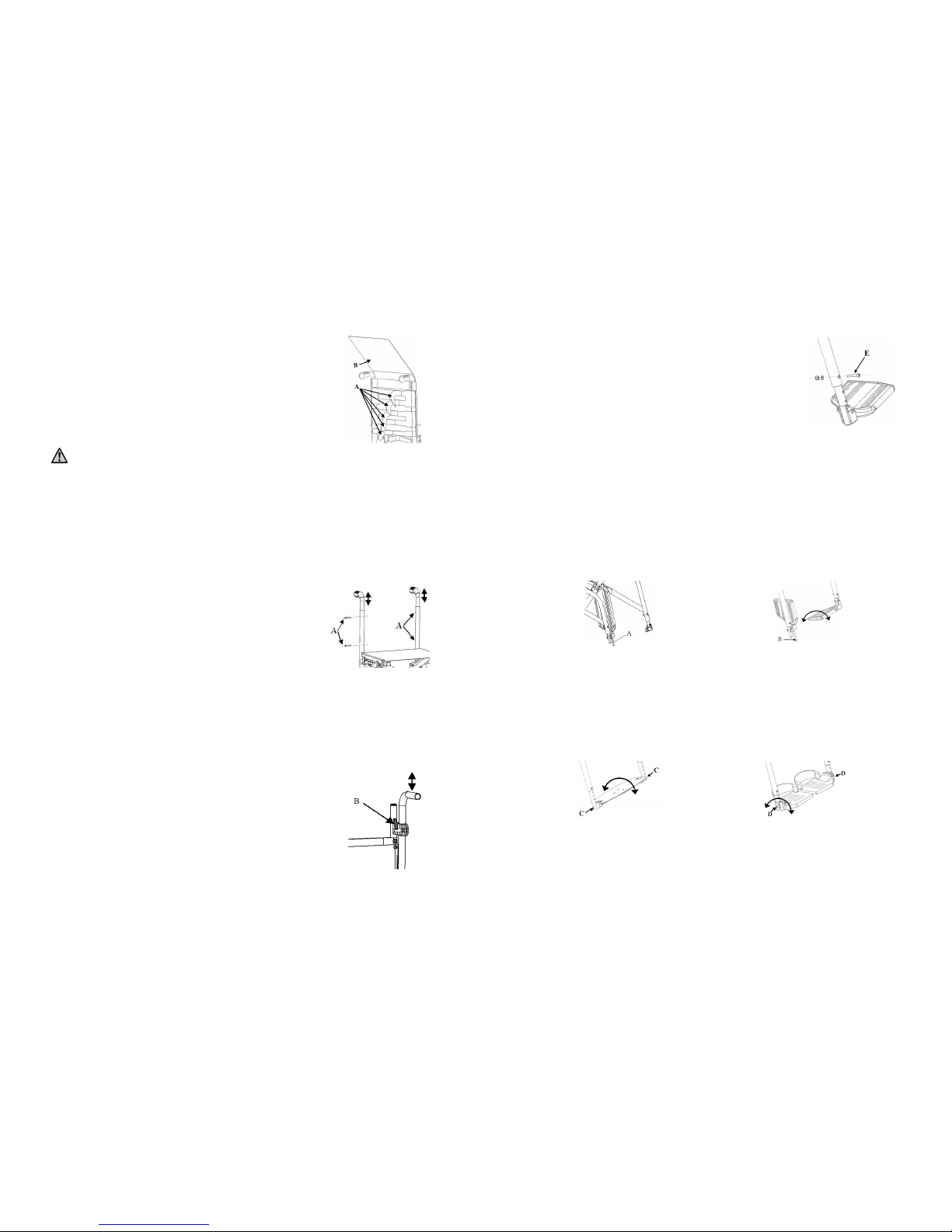

4. ARM-REST..................................................................................................19

4.1 D

ETACHABLE ARM

-

REST

......................................................................20

4.2 T

IP

-

UP ARM

-

REST

.................................................................................20

4.3 H

EIGHT ADJUSTABLE ARM

-

REST

..........................................................20

4.4 “L”

TYPE ARM

-

REST

.............................................................................21

5. ANTI-TIP DEVICE.....................................................................................22

5.1 C

URVED REAR FRAME ANTI

-

TIP DEVICE

...............................................22

5.2 C

URVED REAR FRAME ANTI

-

TIP DEVICE

...............................................23

5.2.1 Curved rear frame anti-tip device adjustment................................23

5.2.2 Telescopic end terminal adjustment ...............................................23

5.3 S

TRAIGHT REAR FRAME ANTI

-

TIP DEVICE

.............................................23

5.3.1. Height adjustment anti-tip device...................................................24

2

6. DOUBLE PUSHRIM SINGLE DRIVE.....................................................25

7. HINGED BACK-REST...............................................................................26

8. SMALL WHEEL FOR NARROW PASSAGES WITH LEVER............26

9. UNBALANCING SYSTEM........................................................................27

10. EXTENDED WHEEL PLATE...................................................................27

11. STRETCHED BAR .....................................................................................27

12. ELEVATING FOOT-REST .......................................................................28

13. TABLE..........................................................................................................28

14. ABDUCTOR ................................................................................................29

15. LATERAL SUPPORT ................................................................................30

16. HEAD-REST................................................................................................31

17. SPOKES GUARDS......................................................................................31

18. WC SEAT.....................................................................................................31

19. USE OF THE WHEELCHAIR ..................................................................32

20. WARNING TO REDUCE THE RISKS ASSOCIATED WITH MISUSE

OF THE WHEELCHAIR...........................................................................34

21. MAINTENANCE, INSPECTIONS AND CONTROLS...........................35

22. CLEANING INSTRUCTRION..................................................................36

23. TECHNICAL SERVICE.............................................................................37

24. WARRANTY TERMS................................................................................37

25. PACKAGING, SHIPPING AND DELIVERY..........................................38

26. MATERIALS DIFFERENTIATION.........................................................38