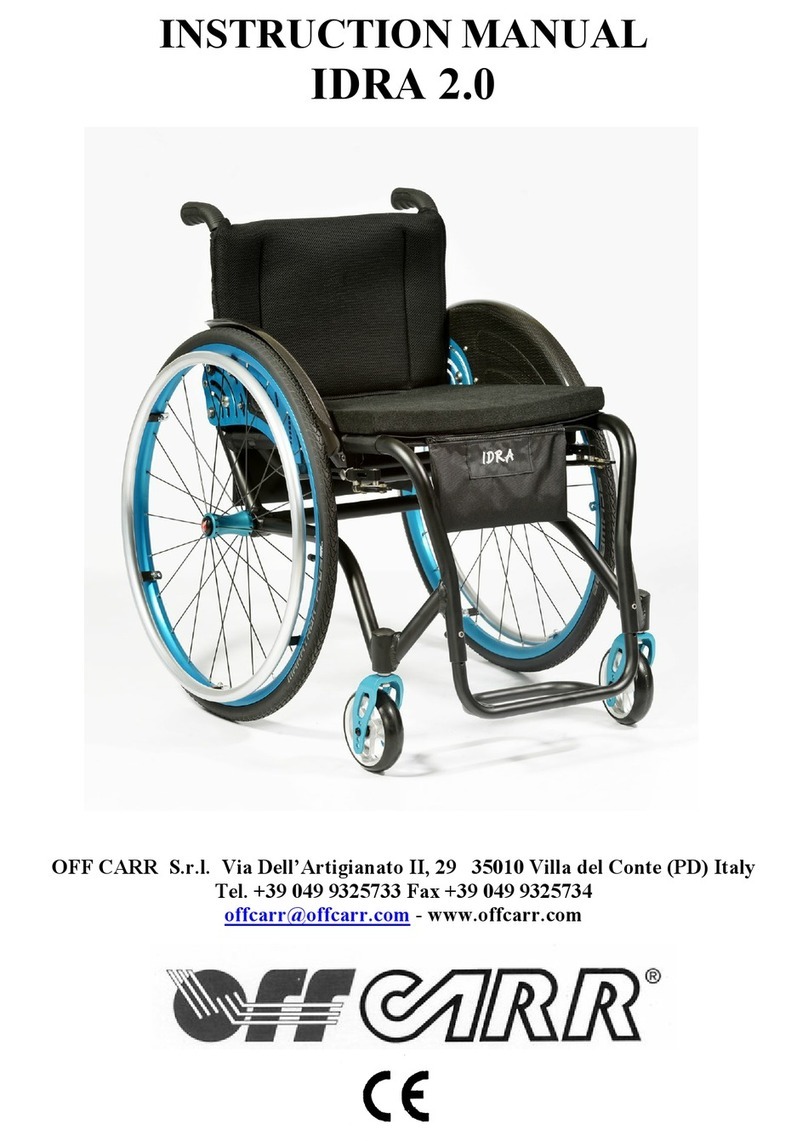

INDEX

1. INTRODUCTION..................................................................................................4

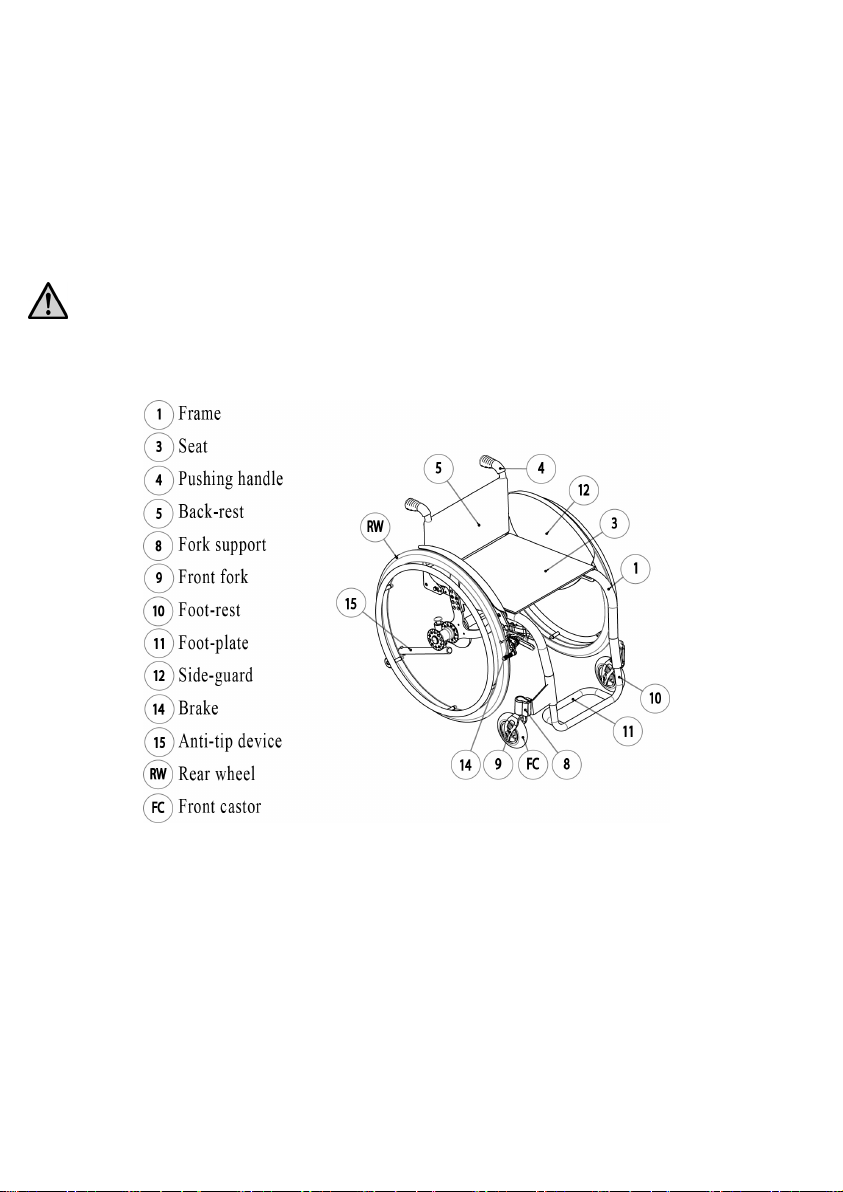

1.1 DESCRIPTION ............................................................................................................................. 4

1.2 FEATURES .................................................................................................................................. 5

2. PREPARATION FOR USE .....................................................................................6

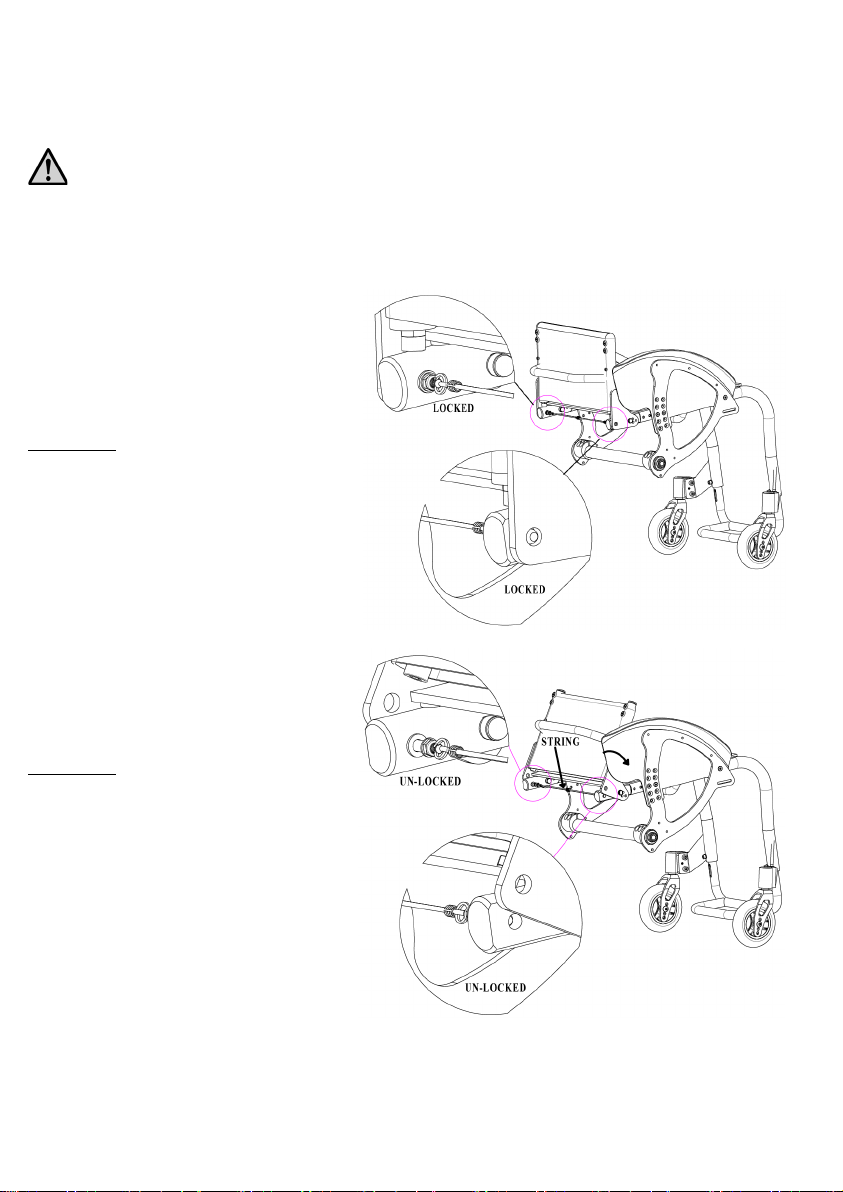

2.1 BACK-REST OPENING/FOLDING .................................................................................................. 6

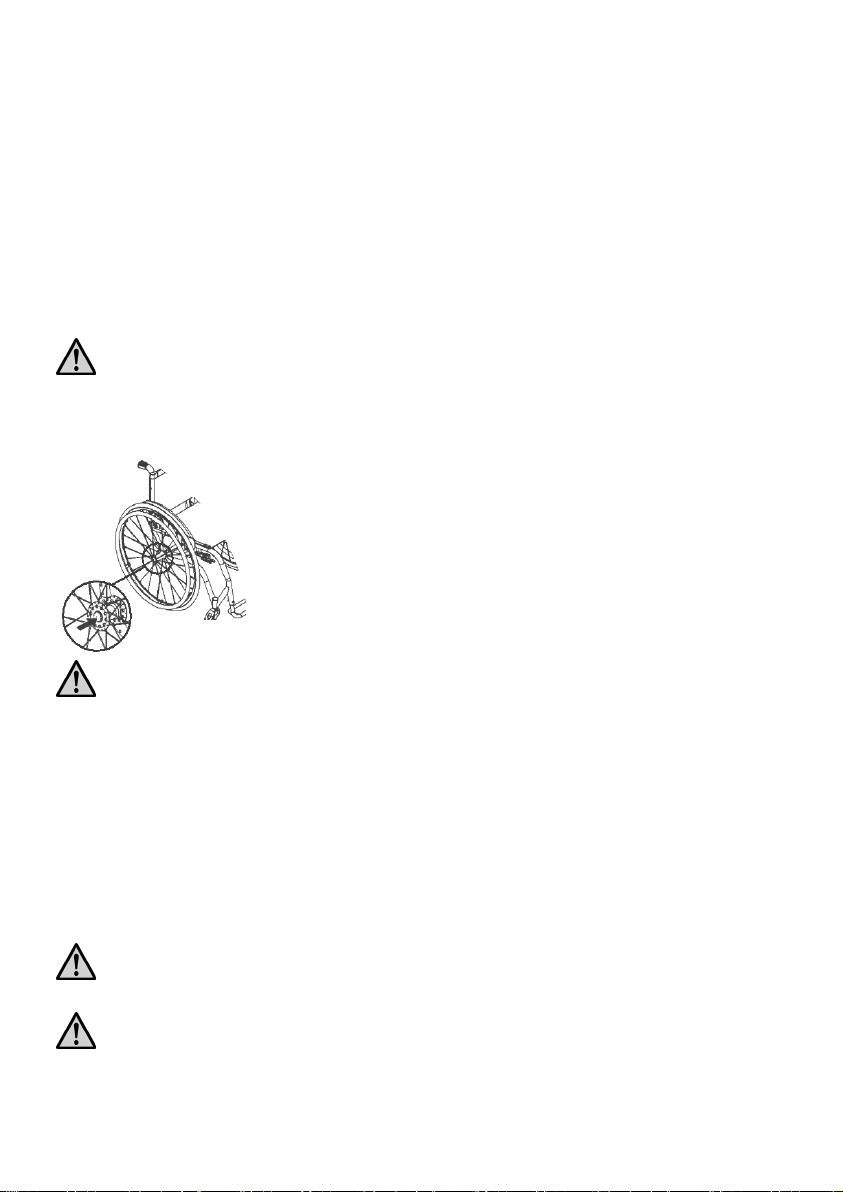

2.2 REAR WHEELS ASSEMBLY AND RELEASE.................................................................................... 7

2.3 TYRE PRESSURE CHECK .............................................................................................................. 7

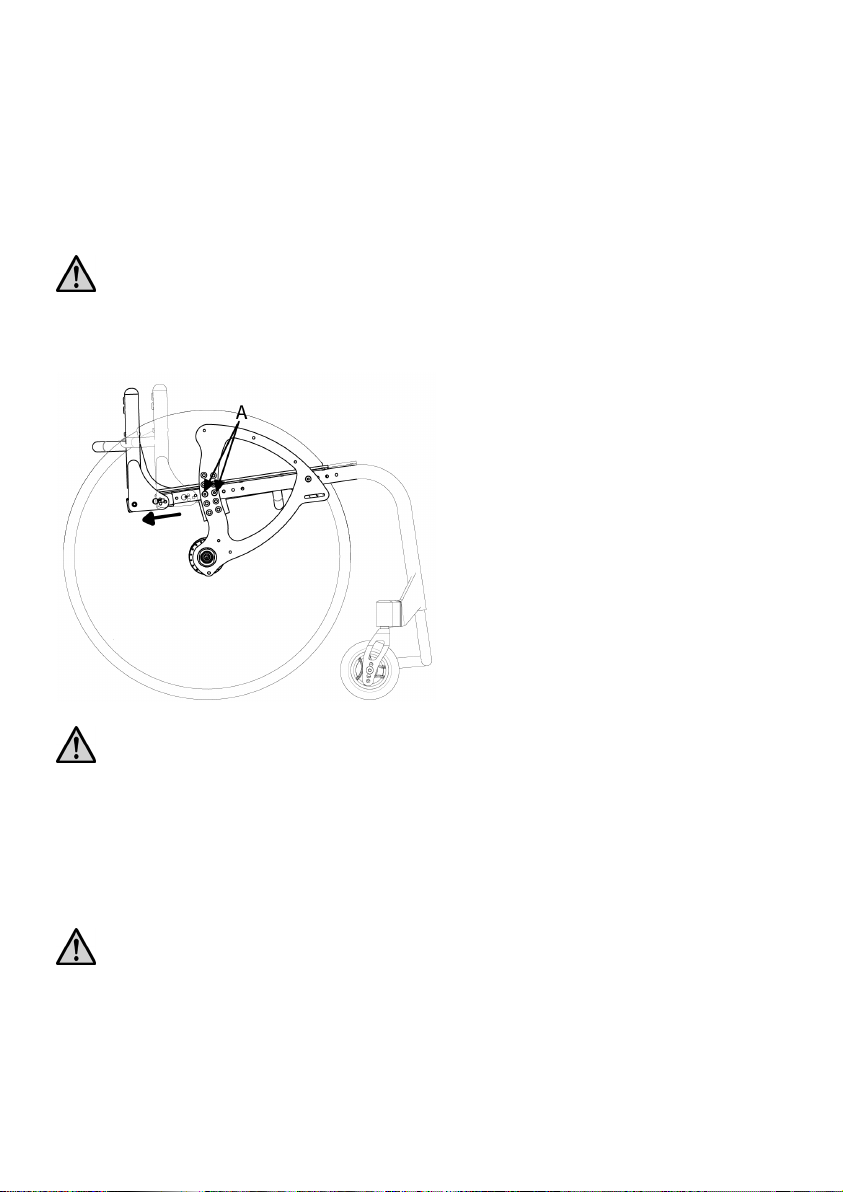

2.4 CHECKING THE BRAKES ............................................................................................................. 8

2.5 CHECKING THE ACCESSORIES..................................................................................................... 8

3. SETTING UP ........................................................................................................9

3.1 SEAT DEPTH ADJUSTMENT.......................................................................................................... 9

3.2 GRAVITY CENTRE ADJUSTMENT ................................................................................................. 9

3.3 REAR SEAT HEIGHT ADJUSTMENT............................................................................................. 11

3.4 FRONT SEAT HEIGHT ADJUSTMENT........................................................................................... 11

3.5 FRONT CASTOR REPLACEMENT ................................................................................................ 12

3.6 REAL WHEEL CAMBER ADJUSTMENT ........................................................................................ 13

3.7 FRONT FORK SUPPORT PLATE ASDJUSTMENT............................................................................ 14

3.8 BACK-REST TILT ADJUSTMENT ................................................................................................. 14

3.9 BACKREST HEIGHT ADJUSTMENT ............................................................................................. 15

3.10 HEIGHT ADJUSTABLE PUSHING HANDLES ................................................................................. 15

3.11 BACKREST TENSION ADJUSTMENT ........................................................................................... 16

3.12 FOOTPLATE TO SEAT DISTANCE ADJUSTMENT .......................................................................... 16

3.13 BRAKE SETUP AND MAINTENANCE ........................................................................................... 17

4. ANTI-TIP DEVICES............................................................................................18

5.1 USE OF THE REVOLVING ANTI-TIP DEVICE ................................................................................ 18

5.2 ADJUSTMENT OF THE ANTI-TIP DEVICE .................................................................................... 19

5.2.1 Adjustment through the rotation of the support plate........................................................ 19

5.2.2 Anti-tip device terminal adjustment.................................................................................. 19

5. UNBALANCING SYSTEM ...................................................................................19

6. ARMRESTS........................................................................................................20

7. CUSHION ..........................................................................................................21

8. SPOKES GUARDS..............................................................................................21

9. USE OF THE WHEELCHAIR...............................................................................21

10. WARNING TO REDUCE THE RISKS ASSOCIATED WITH MISUSE OF THE WHEELCHAIR23

11. MAINTENANCE, INSPECTIONS AND CONTROLS ...............................................24

12. CLEANING INSTRUCTRION...............................................................................25

13. TECHNICAL SERVICE .......................................................................................26

14. WARRANTY TERMS ..........................................................................................26

15. PACKAGING, SHIPPING AND DELIVERY ...........................................................27

16. MATERIALS DIFFERENTIATION .......................................................................27