Index

1. INTRODUCTION ...........................................................................................4

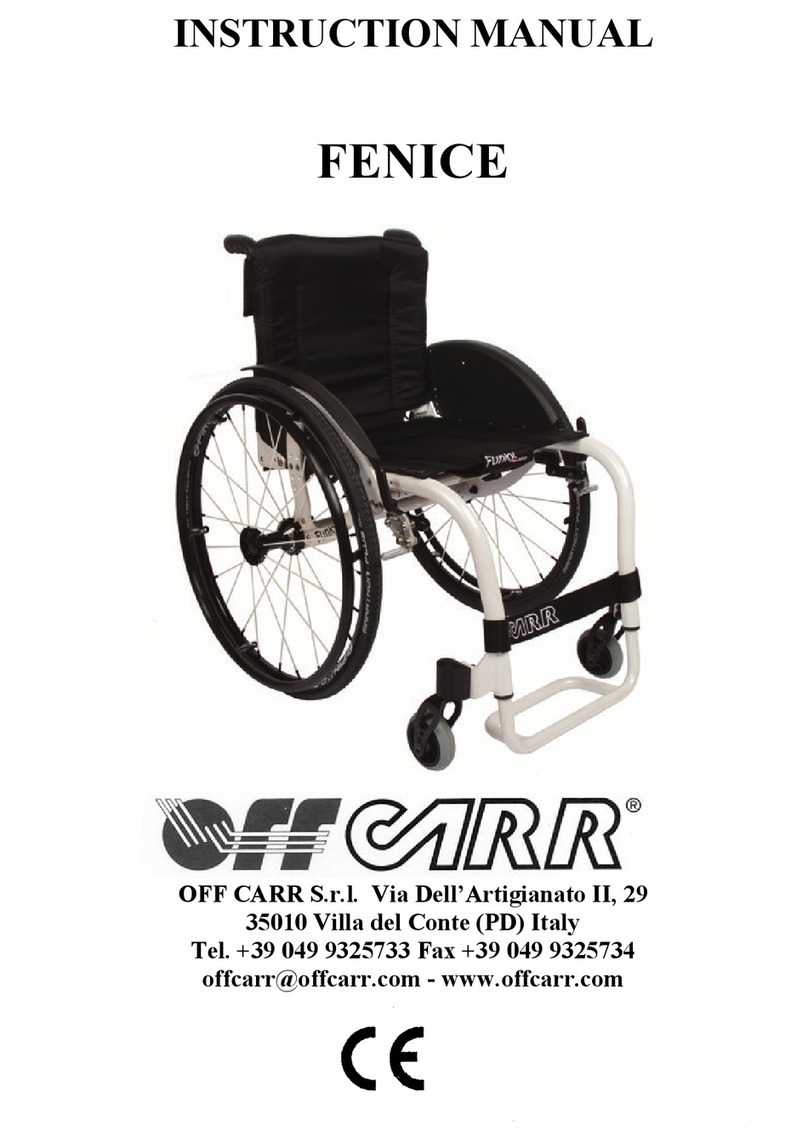

2. IDRA 2.0 DESCRIPTION ..............................................................................4

IDRA 2.0 FEATURES .......................................................................................................... 5

3. PREPARATION FOR USE ............................................................................6

3.1 OPENING/FOLDING THE BACK-REST ............................................................................. 6

3.2 REMOVING/PUTTING IN PLACE THE REAR WHEELS........................................................ 6

3.3 TYRE PRESSURE CHECK ............................................................................................... 7

3.4 BRAKES CHECK ........................................................................................................... 8

3.5 ACCESSORIES CHECK................................................................................................... 8

4. IDRA 2.0 SETUP .............................................................................................9

4.1 CHANGING THE GRAVITY CENTRE ................................................................................ 9

4.2 SETTING THE BACKREST TILT AND CLOTHES GUARDS POSITION..................................... 9

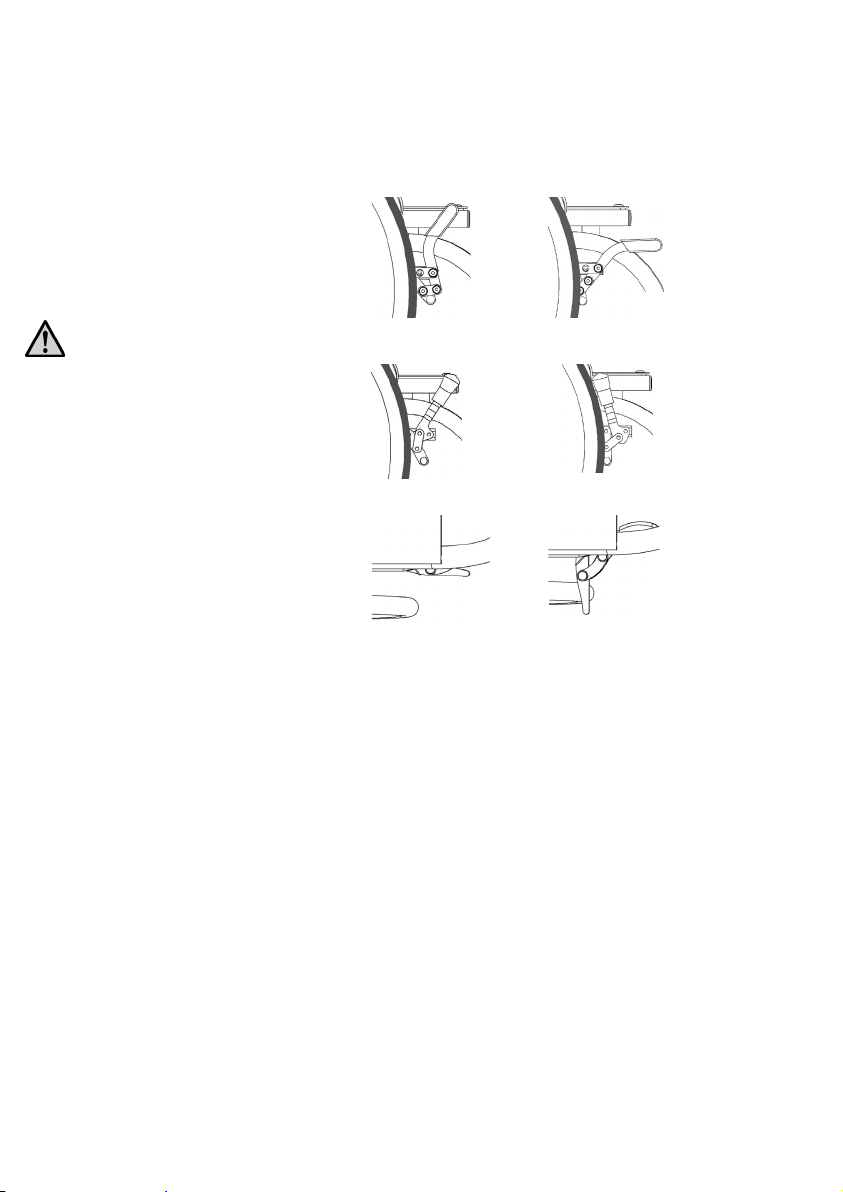

4.3 SETUP AND MAINTENANCE OF BRAKES....................................................................... 10

4.4 REPLACING THE FRONT CASTORS ............................................................................... 11

4.5 BACKREST TENSION ADJUSTMENT ............................................................................. 11

4.6 BACKREST HEIGHT ADJUSTMENT ............................................................................... 11

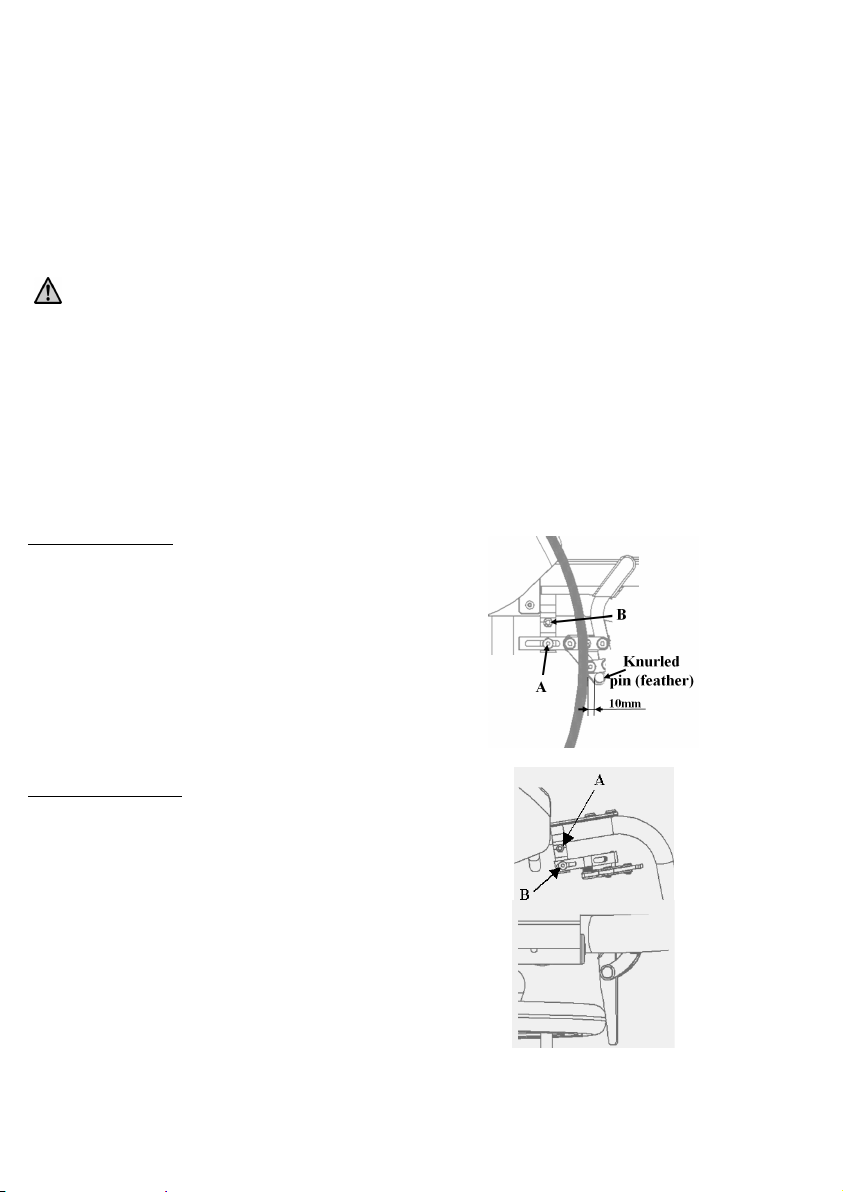

4.7 HEIGHT ADJUSTABLE PUSHING HANDLES ................................................................... 12

4.8 FOOTPLATE TO SEAT DISTANCE ADJUSTMENT............................................................. 13

4.9 SETTING THE REAL WHEEL CAMBER ........................................................................... 13

5. IDRA 2.0 ANTI-TIP DEVICE......................................................................14

5.1 USE OF THE ANTI-TIP DEVICE ..................................................................................... 14

5.2 ANTI-TIP DEVICE ADJUSTMENT.................................................................................. 15

5.2.1 Adjustment through fixing plates 15

5.2.2 Terminal adjustment 15

6. SPOKES GUARDS........................................................................................15

7. USE OF THE WHEELCHAIR ....................................................................16

8. KEY MEASURES TO BE TAKEN TO LIMIT THE RISKS

CONNECTED WITH MISUSE OF THE WHEELCHAIR ......................18

9. MAINTENANCE, INSPECTIONS AND CONTROLS .............................19

10. CLEANING INSTRUCTIONS ....................................................................20

12. WARRANTY TERMS ..................................................................................22

13. PACKAGING, SHIPPING AND DELIVERY............................................23

14. MATERIALS DIFFERENTIATION...........................................................23