3.1.7

Line feed circuit ..........................................................

3-9

3.1.8 Alarmcircuits ............................................................

3-9

3.1.9

Paper end detection circuit

...............................................

3-10

3.1.10

Powersupply ...........................................................

3-11

3.2

Mechanical Operation

...................................................

3-12

3.2.1

The printhead mechanism and its operation

...............................

3-12

3.2.2 Spacing ................................................................

3-14

3.2.3

Head gap adjusting

......................................................

3-16

3.2.4

Ribbon drive

............................................................

3-18

3.2.5 Paperfeed ..............................................................

3-20

3.2.6

Paper end detection

.....................................................

3-27

3.2.7

Semi-automatic sheet feeder

(SASF)

.......................................

3-28

3.2.8

Reversing continuoussheets

..............................................

3-31

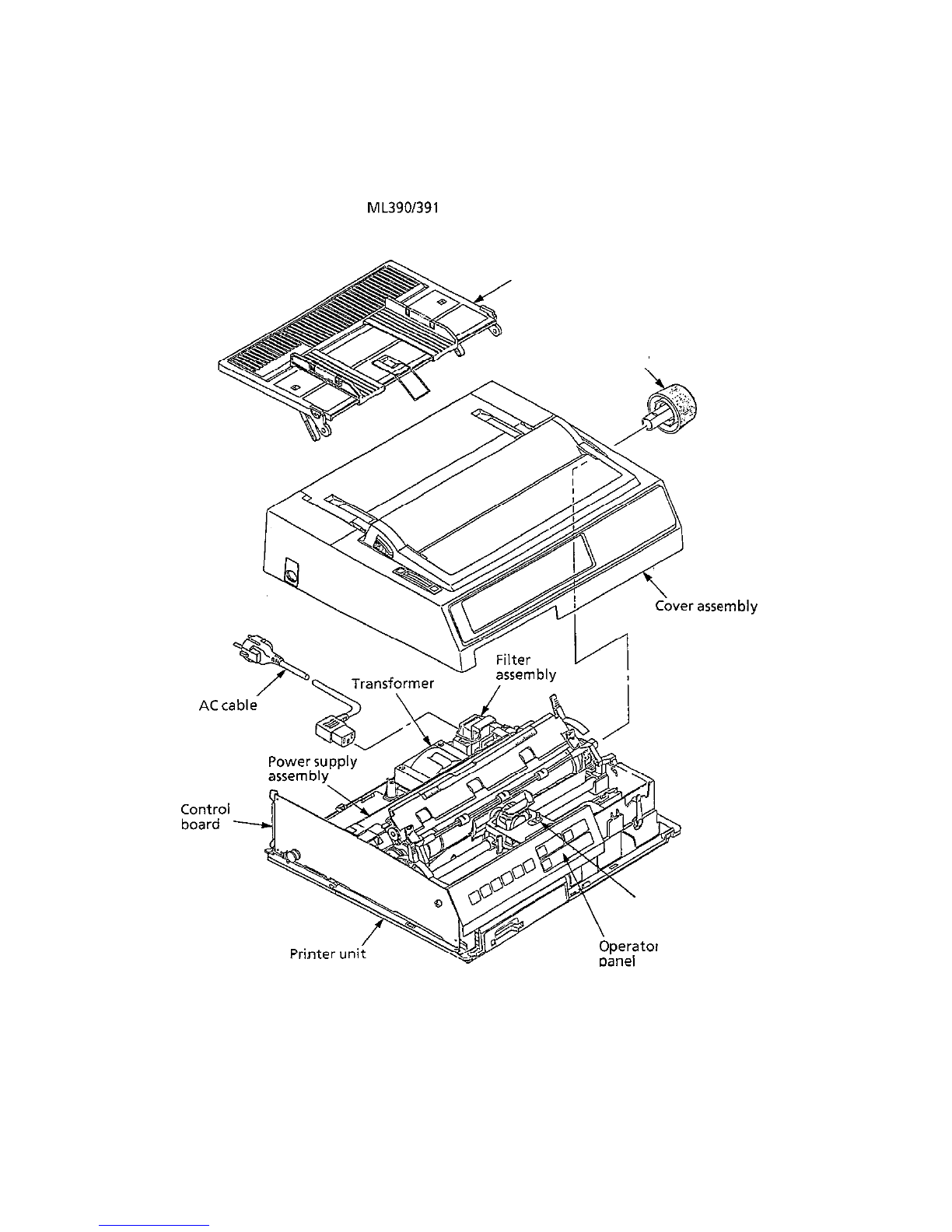

4.

ASSEMBLY/DISASSEMBLY

...................................................

4-l

4.1

Precautions for Parts Replacement 4-l

4.2

MaintenanceTools

.......................................................

4-2

4.3

Disassembly/Reassemblyof Procedure

......................................

4-3

4.3.1 Separatorassembly .......................................................

4-4

4.3.2 Printhead ................................................................

4-5

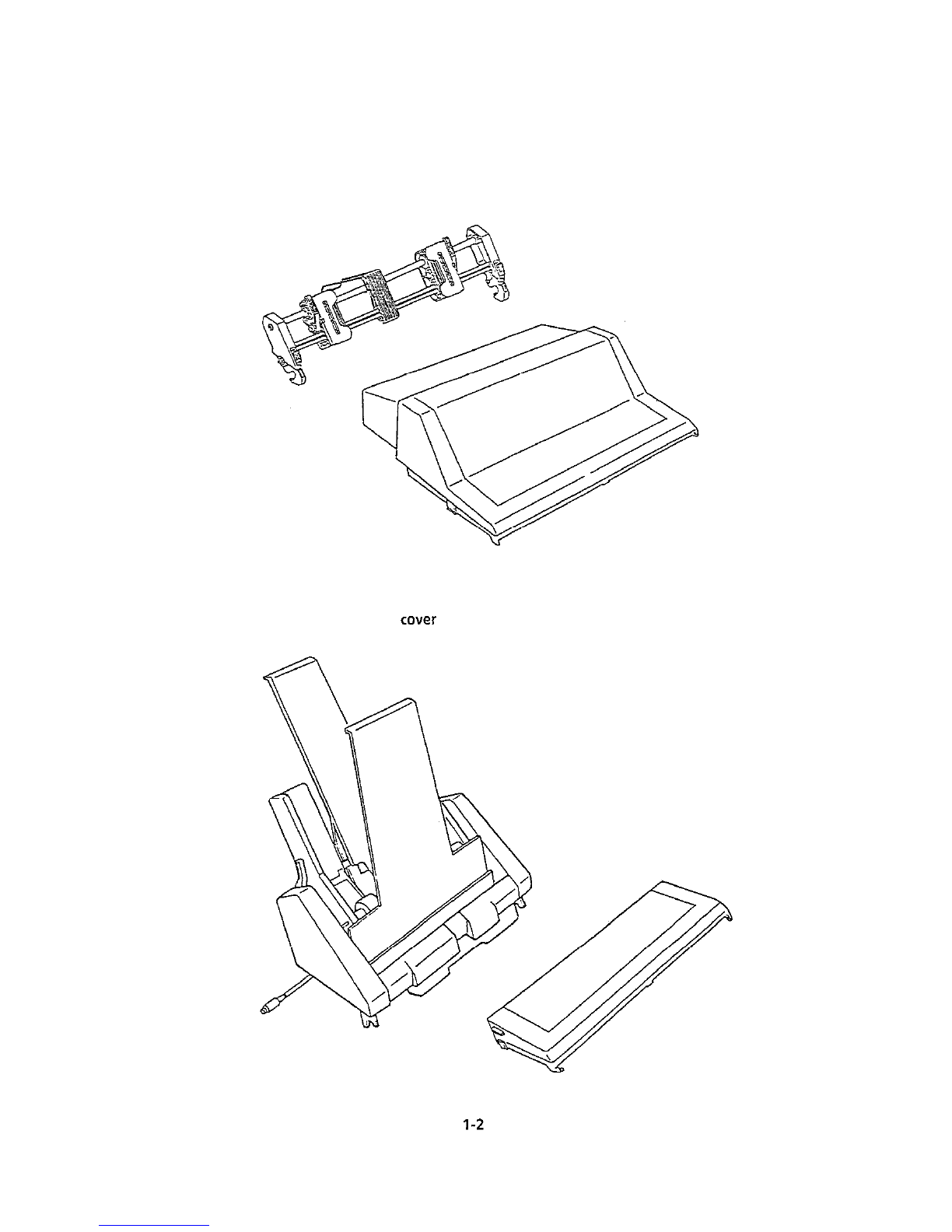

4.3.3

Uppercoverassembly

.....................................................

4-6

4.3.4 Controlboard ............................................................

4-8

4.3.5

Operator board

.........................................................

4-10

4.3.6

Bailarm

.............................................................

4-12

4.3.7

Connection board

(SRBS)

.................................................

4-12

4.3.8 ICcardpanel ............................................................

4-14

4.3.9 Bailarmbar .............................................................

4-15

4.3.10 Transformer ............................................................

4-16

4.3.11

Filterassembly

..........................................................

4-17

4.3.12 Power supply board .....................................................

4-18

4.3.13 Connectorcord .........................................................

4-19

4.3.14 Ribbon drive gear assembly

..............................................

4-20

4.3.15

Space motorassembly

...................................................

4-22

ii