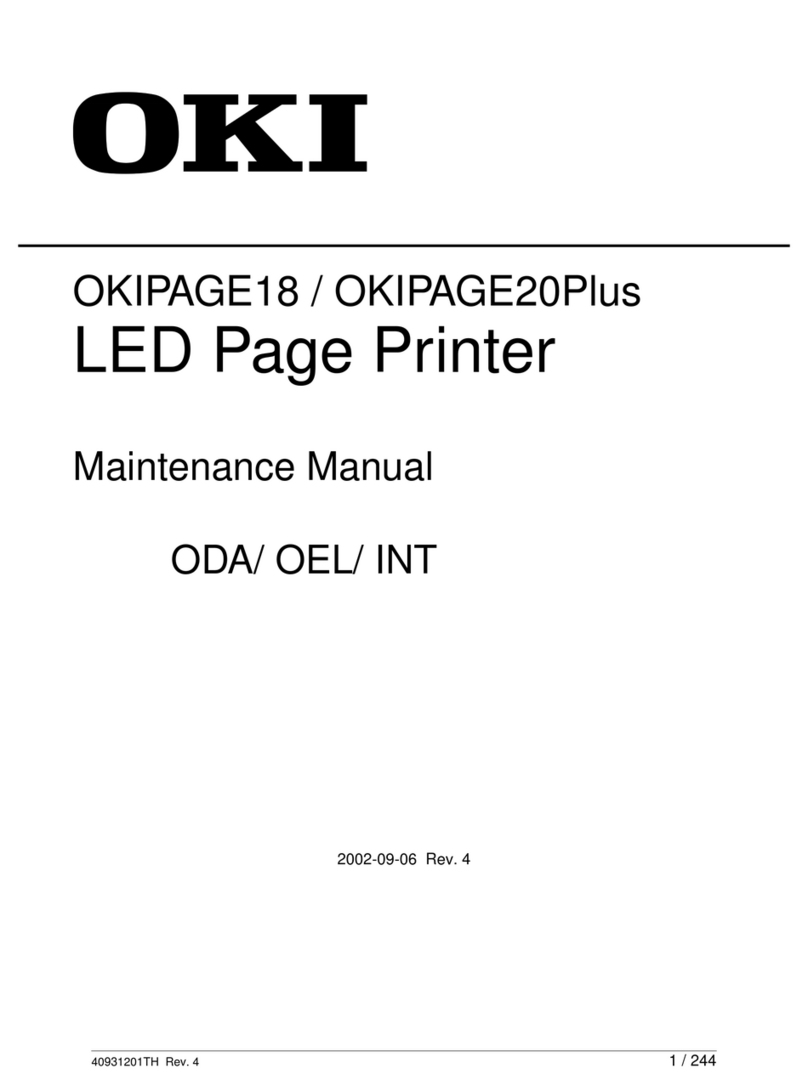

Table of Contents Page

6 Troubleshooting Procedures

6.1 Before Troubleshooting 123

6.2 Checking before Troubleshooting Image Problems 124

6.3 Precautions in Troubleshooting Image Problems 125

6.4 Preparation for Troubleshooting 126

6.5 Troubleshooting 127

....6.5.1 LCD messages list 128

........Table 6-1-1 Operator Alarms (1/2) 129

....6.5.2 LCD Preparation for Troubleshooting 130

........(1) The printer does not operate properly after power-on. 131

........(2) Jams 132

............(2)-1 Paper Loading Jam (1st Tray) 133

............(2)-2 Paper Loading Jam (Multi-Purpose Tray) 134

............(2)-3 Paper feed jam 135

............(2)-4 Paper Exit Jam 136

............(2)-5 Duplex Jam 137

........(3) Paper Size Error 138

........(4) Image Drum Unit (ID) Up-and-Down Operation Error 139

........(5) Fusing Unit Error 140

........(6) Motor Fan Error 141

....6.5.3 Troubleshooting image problems 142

........(1) Light or Faded Image on Whole Page, or Color

Misalignment on Whole Page (Figure 6-2 A)

143

........(2) Dirty Background (Figure 6-2 B) 144

........(3) Blank Page (Figure 6-2 C) 145

........(4) Vertical Belt or LIne (Black or Color Belt, or Black or

Color Line) (Figure 6-2 D)

146

........(5) Vertical White Belt or Line, or Uneven-Color Belt or

Line (Figure 6-2 F)

147

........(6) Poor Fusing (Ink spreads or peels when touched with

fingers)

148

........(7) Defective Image of Regular Interval (See Figure 6-2 E) 149

........(8) Missing Image 150

........(9) Color Misalignment 151

........(10) Color Different from Original One 152

........Figure 6-3 153

7 Wiring Diagram

7.1 Resistance Check 154

7.2 Program/Font ROM Location 155

8 Parts List

Main Assembly - Figure 8-2 156

Main Assembly - Table 8-1 (1/3) 157

Main Assembly - Table 8-1 (2/3) 158

Main Assembly - Table 8-1 (3/3) 159

Top Cover Assembly - Figure 8-2 160