41605601TH Rev.2 4 /

Contents

1. CONFIGURATION ............................................................................................... 7

1.1 System Configuration ................................................................................... 7

1.2 Printer Configuration..................................................................................... 8

1.3 Optional Configuration .................................................................................. 9

1.4 Specification ................................................................................................11

1.5 Safety Standards ........................................................................................ 13

1.5.1 Certification Label.................................................................................................... 13

1.5.2 Warning Label.......................................................................................................... 13

1.5.3 Warning/Caution Marking ........................................................................................ 14

2. OPERATION DESCRIPTION............................................................................. 15

2.1 Main Control Board..................................................................................... 17

2.2 Power Supply/Sensor Board....................................................................... 18

2.3 Electrophotographic Process...................................................................... 20

2.3.1 Electrophotographic Process Mechanism ............................................................... 20

2.3.2 Electrophotographic Process................................................................................... 22

2.3.3 Process Operation Descriptions .............................................................................. 25

2.4 Paper Jam Detection .................................................................................. 35

2.5 Cover Open ................................................................................................ 37

2.6 Toner Low Detection ................................................................................... 38

3. PARTS REPLACEMENT.................................................................................... 40

3.1 Precautions for Parts Replacement ............................................................ 40

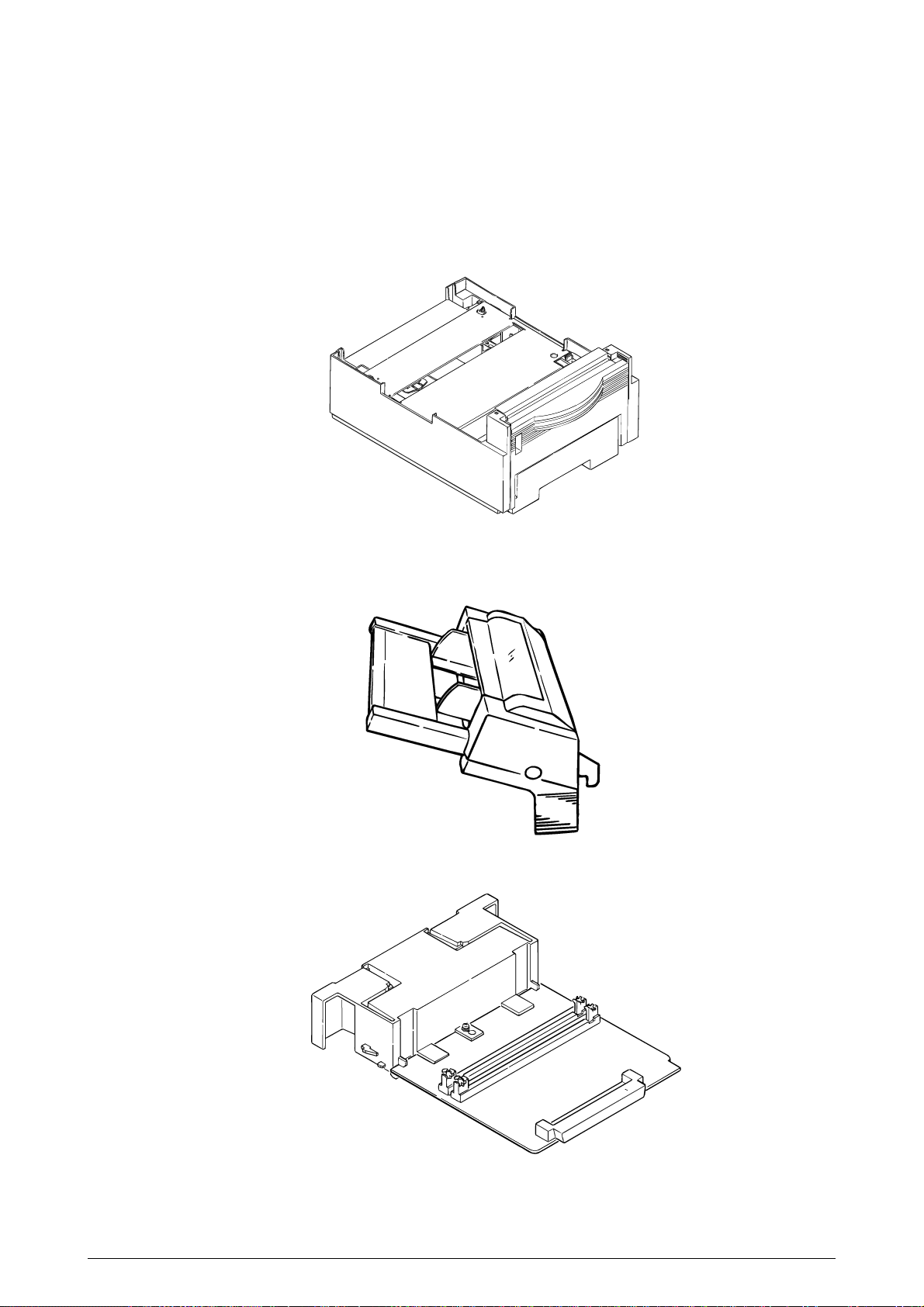

3.2 Parts Layout................................................................................................ 42

3.3 How to Change Parts.................................................................................. 45

3.3.1 Upper Cover Assy.................................................................................................... 46

3.3.2 IC Card Cover.......................................................................................................... 47

3.3.3 LED Head ................................................................................................................ 48

3.3.4 Operator Panel Assy................................................................................................ 49

3.3.5 Lower Base Unit ...................................................................................................... 50

3.3.6 Pulse Motor (Main/Drum) ........................................................................................ 51

3.3.7 Pulse Motor (Registration)....................................................................................... 52

3.3.8 Face Up Stacker Assy ............................................................................................. 53

3.3.9 Eject Roller Assy...................................................................................................... 54

3.3.10 Motor Assy............................................................................................................... 55

3.3.11 Hopping Roller ShaftAssy....................................................................................... 56

3.3.12 Stacker Cover Assy ................................................................................................. 57

3.3.13 Registration Roller ................................................................................................... 58

3.3.14 Roller Transfer Assy ................................................................................................ 59

3.3.15 Fusing Unit .............................................................................................................. 60

3.3.16 Back-up Roller ......................................................................................................... 61

3.3.17 Sensor Plate (Inlet).................................................................................................. 62

3.3.18 Sensor Plate (Outlet), Sensor Wire Assy................................................................. 63

3.3.19 Manual Feed Guide Assy ........................................................................................ 64

3.3.20 Sensor Plate (Paper Supply) ................................................................................... 65

3.3.21 M7G-PCB ................................................................................................................ 66

3.3.22 Power Supply/Sensor Board, High Voltage Unit and Contact Assy......................... 67

3.3.23 Cassette Guide LAssy ............................................................................................ 68

3.3.24 Cassette Guide R Assy............................................................................................ 69

3.3.25 Spacer Bearing (L/R)............................................................................................... 70

4. ADJUSTMENT ................................................................................................... 71

4.1 Adjustment Types and Functions................................................................ 71

4.1.1 Status Monitor ......................................................................................................... 71