5

Table of Contents Page Number

Warranty........................................................................................................................................................ 2

Warnings ....................................................................................................................................................3-4

Table of Contents .......................................................................................................................................... 5

Specifications ................................................................................................................................................ 5

Receiving the planer ..................................................................................................................................... 6

Unpacking the Machine................................................................................................................................. 6

Machine Preparation and Setup.................................................................................................................... 7

Assembly....................................................................................................................................................... 7

Knife Replacement ........................................................................................................................................ 8

Switch safety lock.......................................................................................................................................... 8

Lubrication Schedule..................................................................................................................................... 9

Depth of Cut ................................................................................................................................................ 10

Pulley Alignment.......................................................................................................................................... 10

V-belt Tensioning ........................................................................................................................................ 10

Feed Speed................................................................................................................................................. 11

Return Rollers ............................................................................................................................................. 11

Feed Rollers ................................................................................................................................................ 11

Table Rollers ............................................................................................................................................... 12

Table Parallelism......................................................................................................................................... 12

Feed Rollers and Chip breaker ................................................................................................................... 13

Adjustment of Chip Breaker.................................................................................................................. 14

Adjustment of Feed Rollers .................................................................................................................. 14

Digital Readout............................................................................................................................................ 15

Parts .......................................................................................................................................................16-25

Specifications

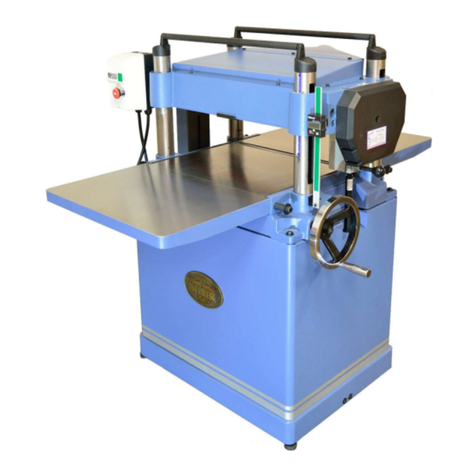

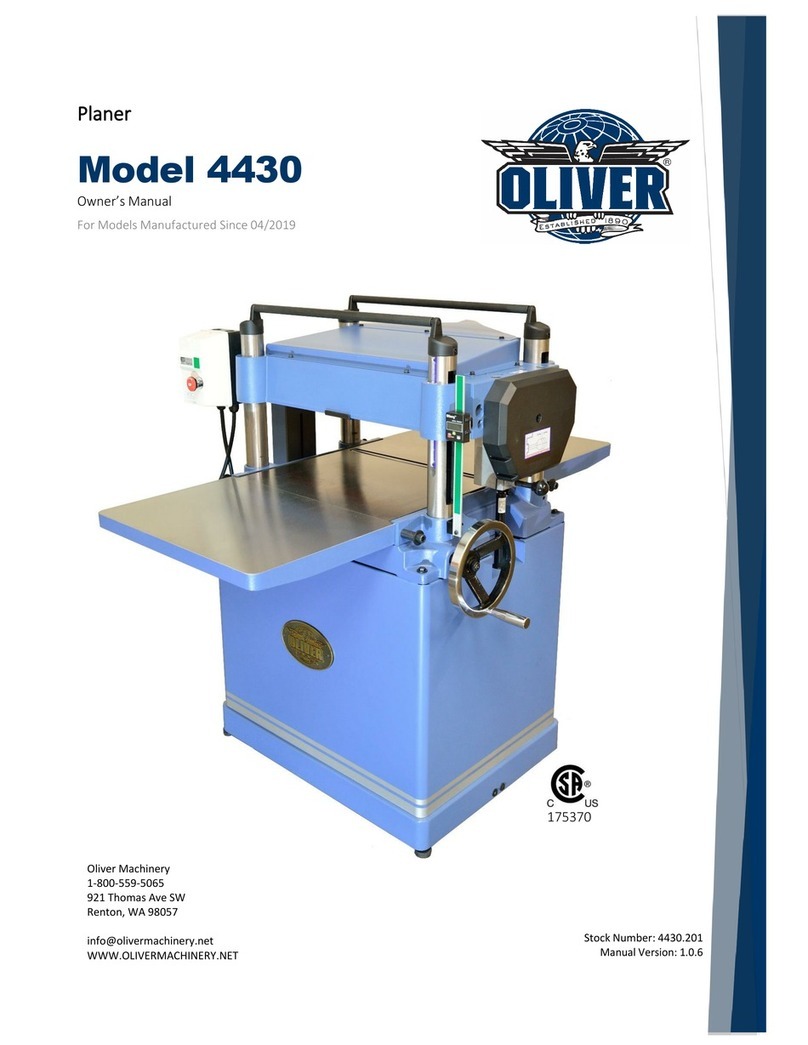

Stock No......................................................................................... (5HP, 1Ph Helical Cutterhead) 4420.001

Maximum Stock Width (in.) ......................................................................................................................... 16

Maximum Depth of Cut (in.) ....................................................................................................................... 1/8

Maximum Stock Thickness (in.) .................................................................................................................... 6

Minimum Stock Thickness (in.) .................................................................................................................. 1/8

Minimum Stock Length (in.) .......................................................................................................................... 6

Dust Port Diameter (in.) ................................................................................................................................ 4

Minimum CFM Required ........................................................................................................................... 600

Feed Speeds (FPM)........................................................................................................................ 16 and 20

Bed Rollers................................................................................................................................. 2, Adjustable

Overall Dimension When Assembled (L x W x H in.)............................................................ 48 x 28 x 43-1/2

Cutterhead Diameter (in.)........................................................................................................................2-7/8

Number of Knives........................................................................................................................................ 90

Cutterhead Speed (RPM)........................................................................................................................ 4800

Motor .............................................................................................................................5HP, 1Ph, 220V Only

Gross Weight (lbs.).................................................................................................................................... 675