Table of Contents

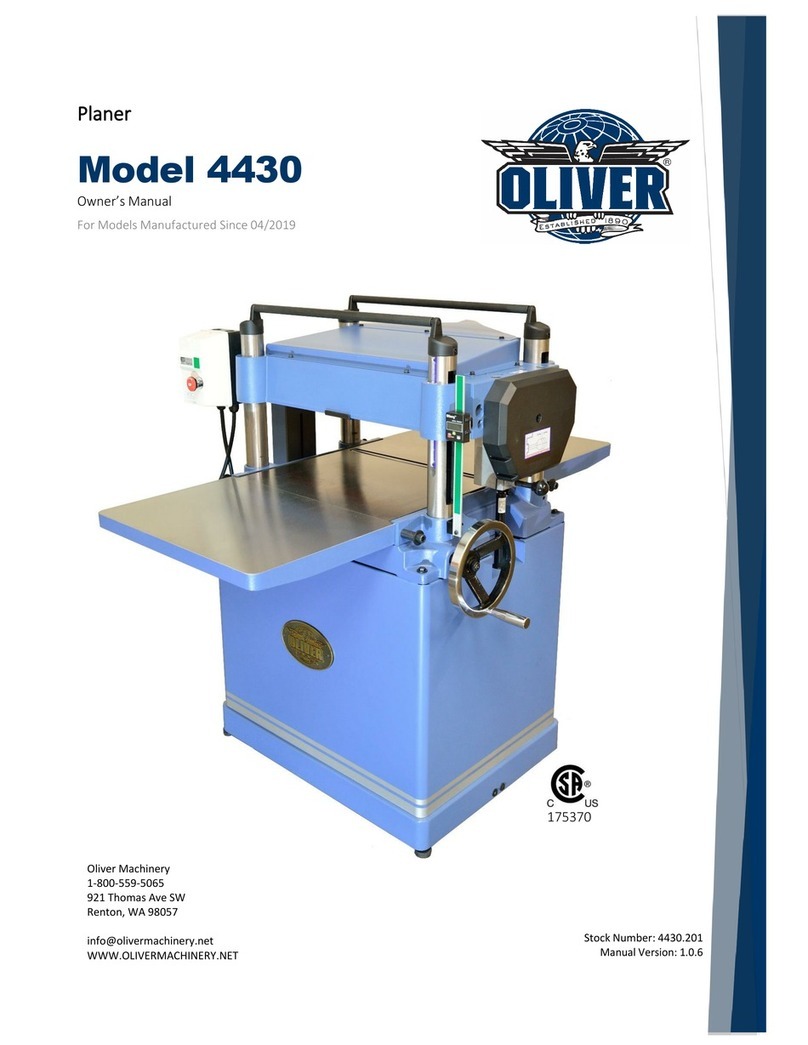

Introduction···················································6

Specifications·················································7

Quick View·················································7

Product Dimensions····································7

Shipment Info·············································7

Electricals···················································7

Motor ························································8

Planer Capacity and Performance ···············8

Cutterhead and Headstock··························8

Measurements ···········································8

Table··························································9

Safety·························································9

Others························································9

Identification ···············································10

Safety ··························································13

General Safety Guidelines·························13

Safety Guidelines Specific to Planer···········14

Electricals·····················································16

Minimum Circuit Size Required for Model

10014 Planer ············································16

Grounding ················································16

Electrical Wiring ·······································16

Setup ···························································18

Shop Preparation······································18

Space Requirement ··································18

Load Limits ···············································18

Electricals ·················································18

Lighting ·····················································18

Safety Labels·············································18

Dust Collection ·········································18

Receiving··················································19

Unboxing ·················································19

Inventory ·················································20

Removing Machine from Crate··················21

Cleaning ···················································22

Assembly ·················································22

Installing Height Adjustment Handwheel 23

Installing Dust Hood·································23

Installing Extension Tables·······················24

Dust Collection ·········································26

Wiring and Grounding ······························26

Wiring Instructions··································· 26

Break-in Period·········································26

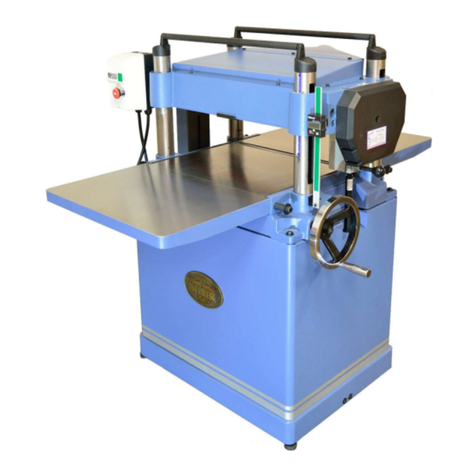

Controls and Components·····························27

ON / OFF Switches····································27

Cutterhead Height Adjustment ·················27

Cutterhead Height Scale ···························27

Digital Readout (DRO)·······························28

Feed Rate Control·····································28

Components for Planing Wood ·················29

Test Run···················································30

Operation ····················································31

Step 1: Preparation···································31

Step 2: Setting Depth of Cut and Feed Rate32

Step 3: Select Feed Direction·····················33

Step 4: Planing Wood to Desired Thickness33

Common Cutting Problems ·······················35

Snipe ························································ 35

Chipping ··················································· 35

Indentation ·············································· 35

Fuzzy Grain···············································35

Accessories ··················································36

Cutter Inserts ···········································36

Touchup Paint ··········································36

Maintenance················································37

Maintenance Schedule ·····························37

Lubrication Schedule ································37

Instructions for Maintenance and

Adjustments ············································39

Remove Planer Top Cover························39

Adjust Chip Deflector Clearance ··············39