Table of Contents Page Number

Warranty ........................................................................................................................................................ 2

Warnings .................................................................................................................................................... 3-4

Table of Contents .......................................................................................................................................... 5

Specifications ................................................................................................................................................ 5

Contents of the Shipping Container .............................................................................................................. 6

Uncrating the Machine .................................................................................................................................. 6

Machine Preparation and Setup ................................................................................................................... 6

Electrical Connections ................................................................................................................................... 7

Assembly ....................................................................................................................................................... 8

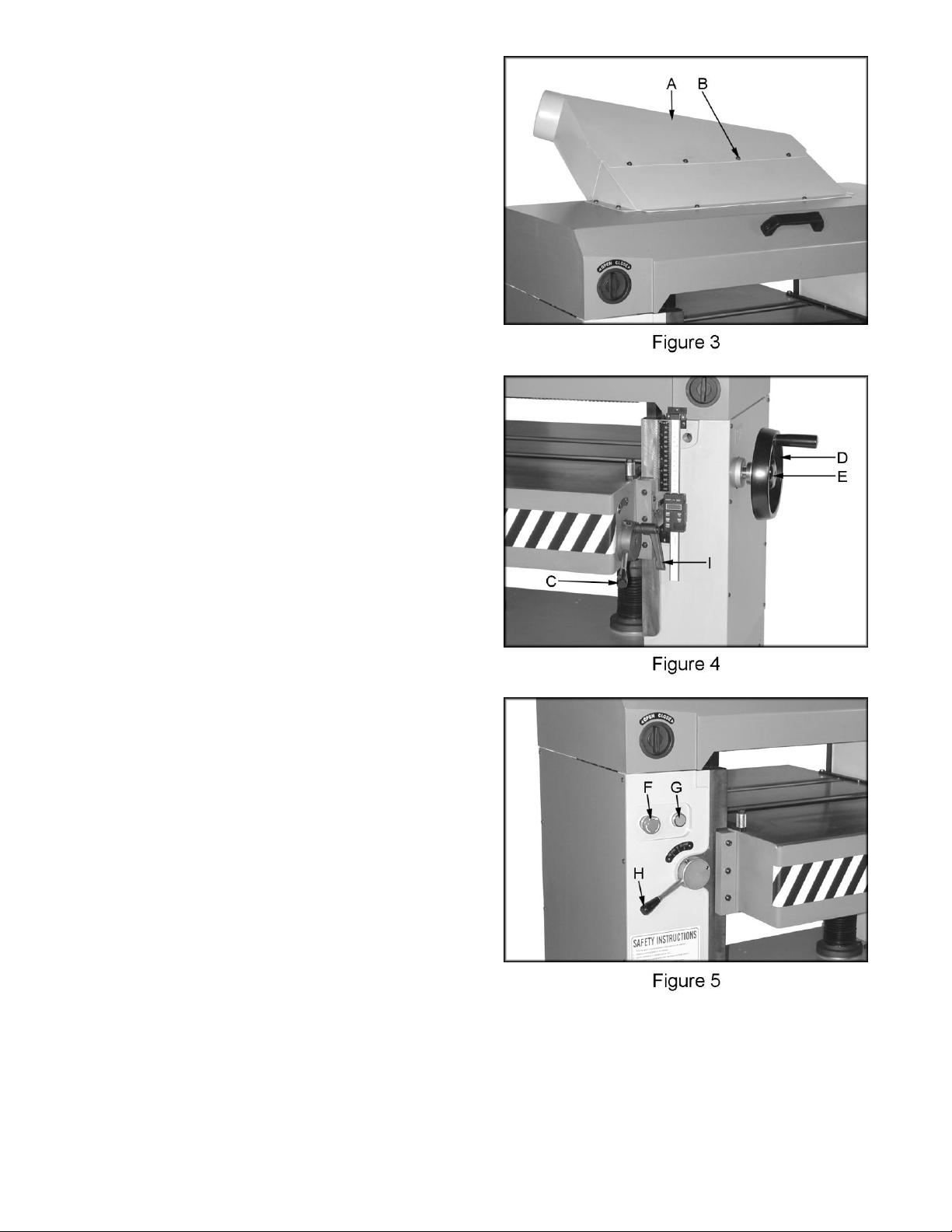

Control Panel ................................................................................................................................................ 8

Changing Feed Rate ..................................................................................................................................... 8

Table Roller Adjustment ................................................................................................................................ 8

Raising and Lowering Table.......................................................................................................................... 9

Table Stop ..................................................................................................................................................... 9

Opening Hood ............................................................................................................................................... 9

Calibrating the Thickness Scale .................................................................................................................... 9

Digital Readout ............................................................................................................................................ 10

Setting / Changing Knives ........................................................................................................................... 11

Helical Cutterhead Option ........................................................................................................................... 12

Setup of Feed Rollers, Chipbreaker and Pressure Bar .............................................................................. 13

Anti-Kickback Fingers ........................................................................................................................... 14

Adjustment of In-Feed Roller ................................................................................................................ 14

Adjustment of Chipbreaker ................................................................................................................... 14

Adjustment of Pressure Bar .................................................................................................................. 15

Adjustment of Out-feed Roller .............................................................................................................. 15

Helical Cutterhead ....................................................................................................................................... 16

V-Belt Adjustment ....................................................................................................................................... 16

Adjusting Table Gibs ................................................................................................................................... 16

Adjusting Table Rollers ............................................................................................................................... 17

Maintenance ................................................................................................................................................ 17

Lubrication ................................................................................................................................................... 18

Troubleshooting .......................................................................................................................................... 19

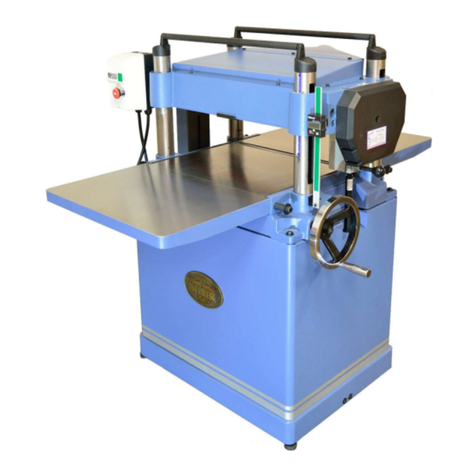

Specifications

Stock No. ..................................................................................... (7.5HP, 1Ph HSS Straight Knife) 4455.001

Stock No. ..................................................................................... (7.5HP, 3Ph HSS Straight Knife) 4455.002

Stock No. ........................................................................ (7.5HP, 1Ph Carbide Helical Cutterhead) 4455.101

Stock No. ........................................................................ (7.5HP, 3Ph Carbide Helical Cutterhead) 4455.102

Maximum Stock Width (in.) ......................................................................................................................... 22

Maximum Depth of Cut (in.) ..................................................................................................................... 3/16

Maximum Stock Thickness (in.) .................................................................................................................... 9

Minimum Stock Thickness (in.) .................................................................................................................. 1/8

Minimum Stock Length (in.) ........................................................................................................................ 10

Dust Port Diameter (in.) ................................................................................................................................ 5

Minimum CFM Required ........................................................................................................................... 900

Segmented Infeed Roller Diameter (in.) ....................................................................................................... 3

Outfeed Roller Diameter (in.) ........................................................................................................................ 3

Feed Speeds (FPM) ........................................................................................................................ 20 and 30

Bed Rollers ................................................................................................................................. 2, Adjustable

Table Size (L x W/in.) .............................................................................................................. 32-1/4 x 23-3/4

Cutterhead Diameter (in.) .............................................................................................................................. 3

Number of Knives .......................................................................................................................................... 4

Cutterhead Speed (RPM) ....................................................................................................................... 5,000

Table Support .................................................................................................................................. 2-Column

Motor .......................................................................................................................... 7.5HP, 1Ph, 220V Only

........................................................................................................ 7.5HP, 3Ph, 220V/440V, Prewired 220V

Gross Weight (lbs.) ................................................................................................................................ 1,568