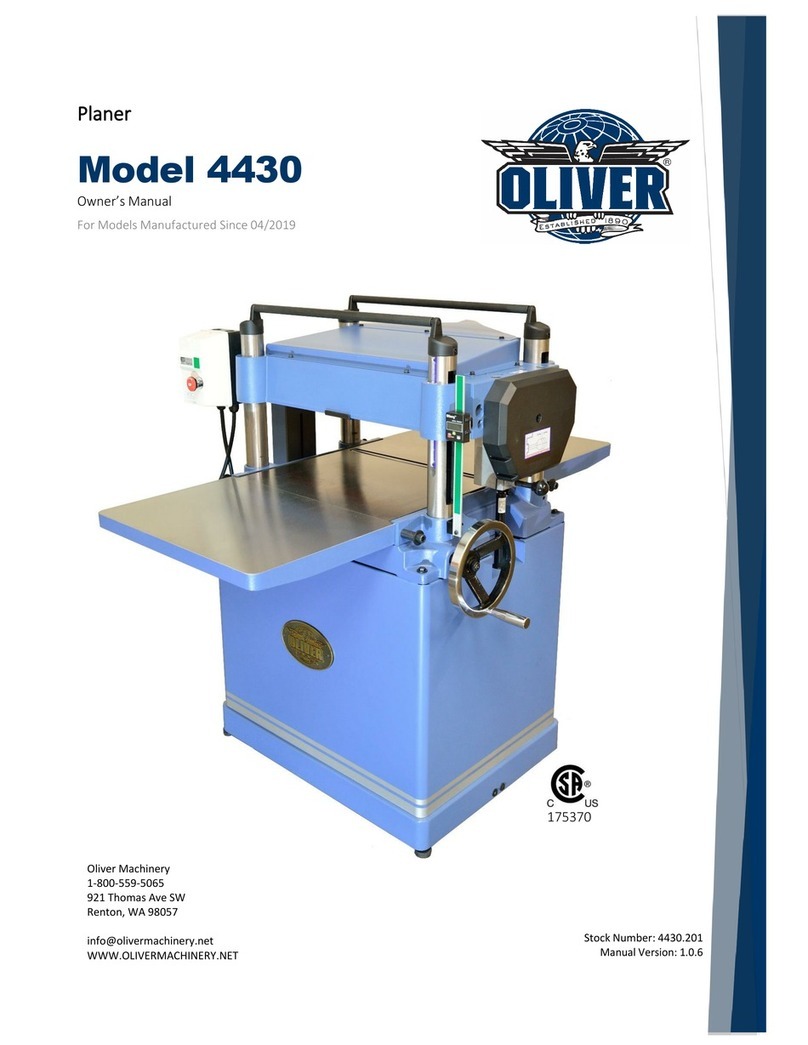

Warranty

Oliver makes every effort possible to assure that its woodworking equipment meets the

highest possible standards of quality and durability. All products sold by Oliver are

warranted to the original customer to be free from defects for a period of 2 (two) years on

all parts, excluding electronics and motors, which are warranted for 1 year. Oliver’s

obligation under this warranty shall be exclusively limited to repairing or replacing (at

Oliver’s option) products which are determined by Oliver to be defective upon delivery

F.O.B. (return freight paid by customer) to Oliver, and on inspection by Oliver. This

warranty does not apply to defects due, directly or indirectly, to misuse, abuse,

negligence, accidents, unauthorized repairs, alterations, lack of maintenance, acts of

nature, or items that would normally be consumed or require replacement due to normal

wear. In no event shall Oliver be liable for death, personal or property injury, or damages

arising from the use of its products.

Warning

Read this manual thoroughly before operating the machine. Oliver Machinery disclaims

any liability for machines that have been altered or abused. Oliver Machinery reserves

the right to effect at any time, without prior notice, those alterations to parts, fittings, and

accessory equipment which they may deem necessary for any reason whatsoever.

For More Information

Oliver Machinery is always adding new Industrial Woodworking products to the line. For

complete, up-to-date product information, check with your local Oliver Machinery

distributor, or visit www.olivermachinery.net