4 | Page Oliver Machinery 4065 Table Saw

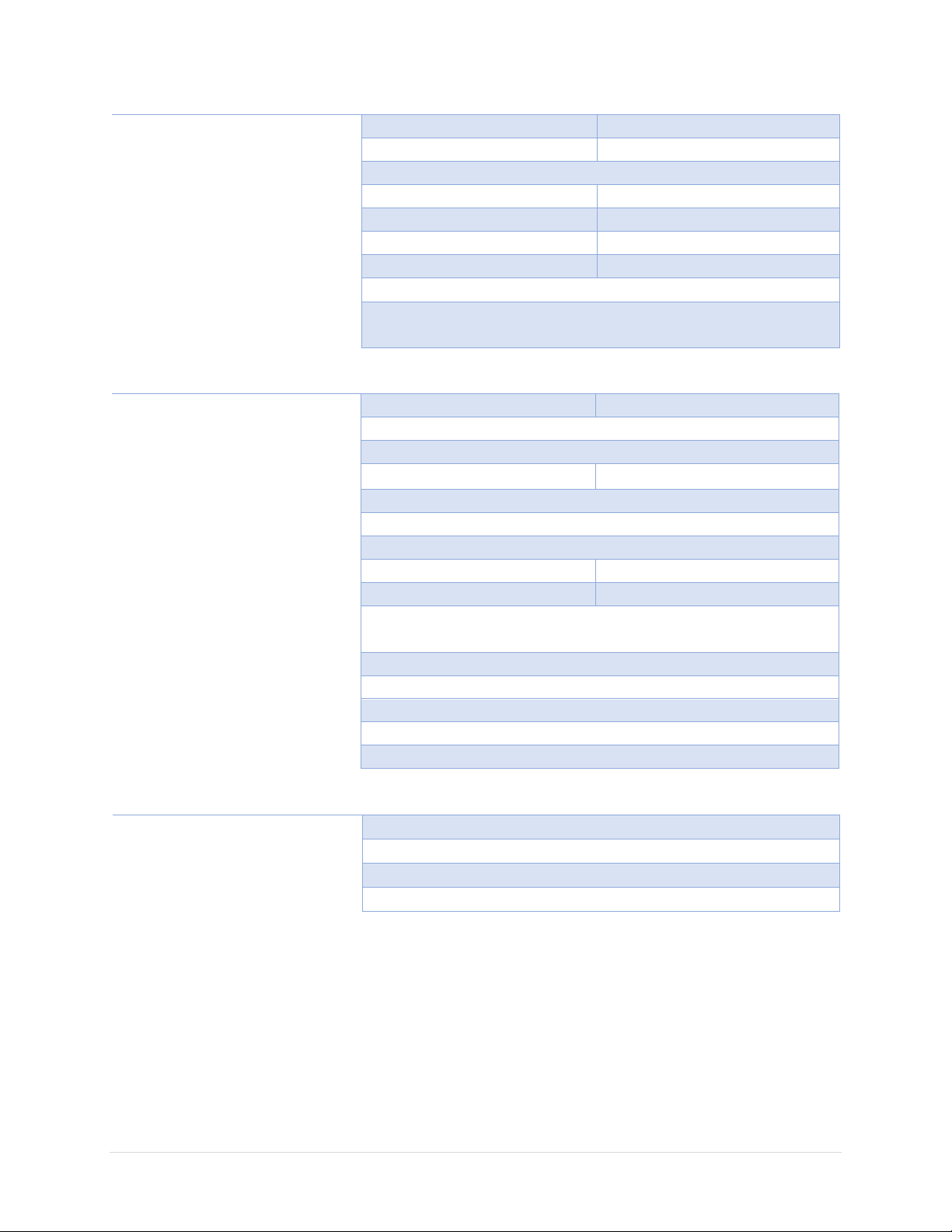

Table of Contents

Introduction...................................................5

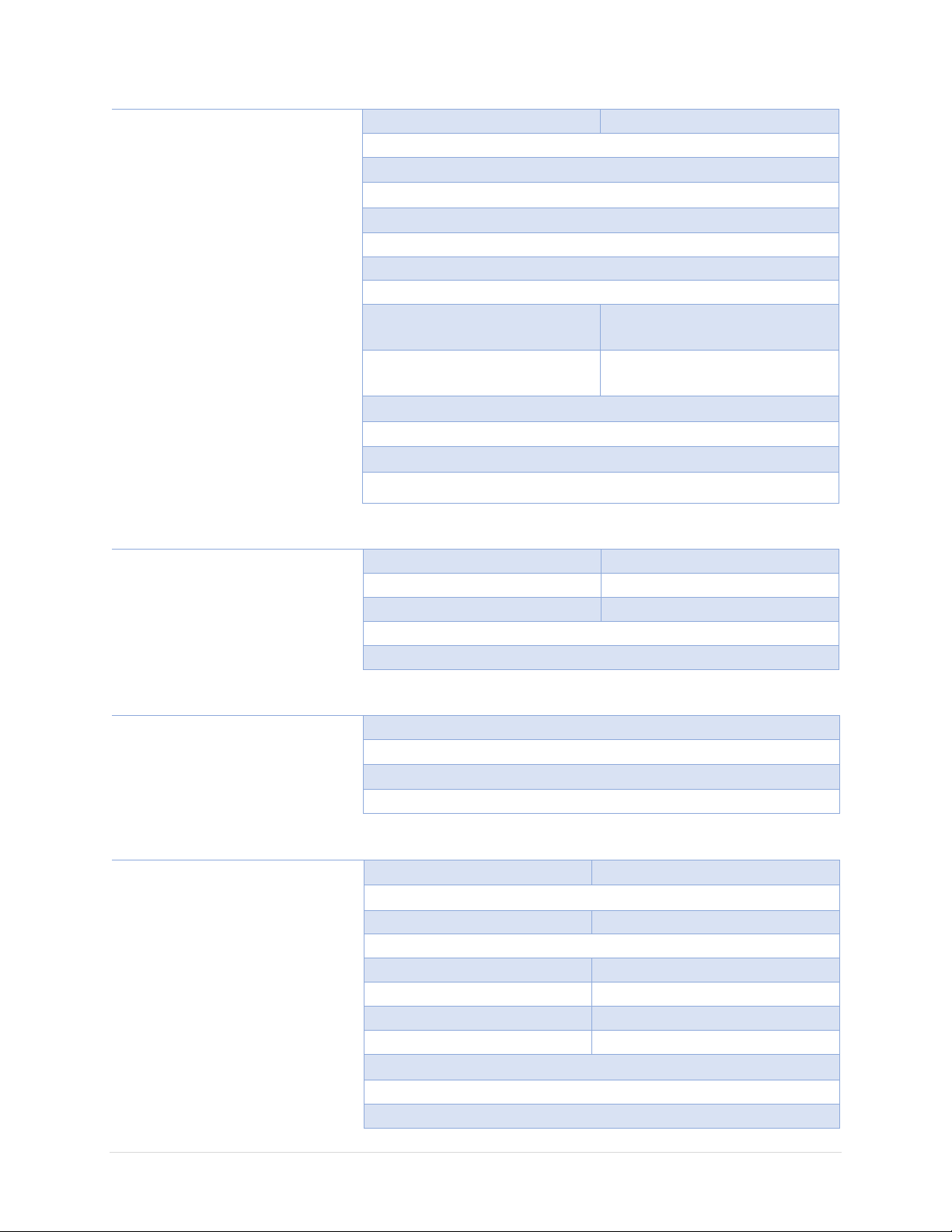

Specifications.................................................6

Identification ...............................................10

Safety ..........................................................12

Electricals.....................................................14

Minimum Circuit Size Required for Model

4065 Table Saw ............................................14

Grounding.....................................................14

Electrical Wiring ...........................................15

230V/460V Conversion.................................16

Setup ...........................................................17

Shop Preparation..........................................17

Receiving ......................................................18

Unboxing & Inventory ..................................19

Lifting Table Saw Main Unit from Pallet.......21

Cleaning........................................................21

Leveling Main Unit........................................22

Essential Mechanical Inspections Before

Assembly ......................................................22

Electrical Connection and Tests ...................26

Assembly .....................................................27

Rails and Extension Table Installation..........27

Fence Setup..................................................30

Dust Collection .............................................32

Moving and Leveling the Saw.......................32

Accessories ..................................................33

Operation ....................................................34

Safety Guidelines for Preparing for a Cut.....34

Safety Guidelines for Using the Table Saw...38

Changing Saw Blade .....................................39

Swapping Riving Knife / Blade Guard ...........40

Using the Digital Readout.............................40

Making a Rip Cut ..........................................41

Making a Cross Cut.......................................43

Making a Miter Cut.......................................45

Making a Bevel Cut.......................................45

Cutting with Dado Set ..................................46

After Using the Table Saw............................ 47

Calibrations and Adjustments.......................48

Blade to Miter Slot Alignment ..................... 48

Fence Lock Tightness Adjustment................ 49

Fence to Miter Slot Alignment..................... 49

Fence Squareness Adjustment.....................50

Fence Height Adjustment ............................50

Fence Scale Adjustment...............................51

Miter Gauge Angle Indicator Adjustment.... 51

Blade Tilt Angle Pointer Adjustment............52

Blade Angle Positive Stops Adjustments...... 52

Spreader/Riving Knife Mounting Bracket

Alignment Adjustment................................. 54

Maintenance................................................55

Dust Accumulation Removal........................ 55

Trunnion Components Cleaning and

Lubrication ...................................................56

Belt Tension Adjustment.............................. 57

Belt Replacement......................................... 58

Table Insert Setup ........................................59

Troubleshooting...........................................61

Wiring Diagrams ..........................................65

For Stock # 4065.002 (230V/460V, 3Ph)...... 65

For Stock # 4065.003 (230V/460V, 3Ph)...... 66

Parts List......................................................67

Table and Blade Guard................................. 67

Cabinet .........................................................68

Motor and Blade Lift Assembly.................... 69

Trunnion Assembly ...................................... 70

Rails ..............................................................71

Extension Table............................................ 72

Rip Fence Assembly...................................... 73

Miter Gauge .................................................74

Maintenance Record ....................................84

Notes...........................................................85

Warranty and Service...................................86