Table of Contents Page Number

Warranty........................................................................................................................................................ 2

Warnings ....................................................................................................................................................3-4

Table of Contents.......................................................................................................................................... 5

Specifications ................................................................................................................................................ 5

Contents of the Shipping Containers ............................................................................................................ 6

Uncrating the Machine .................................................................................................................................. 6

Machine Preparation and Setup ................................................................................................................... 6

Dust Collection .............................................................................................................................................. 7

Electrical Connections................................................................................................................................... 7

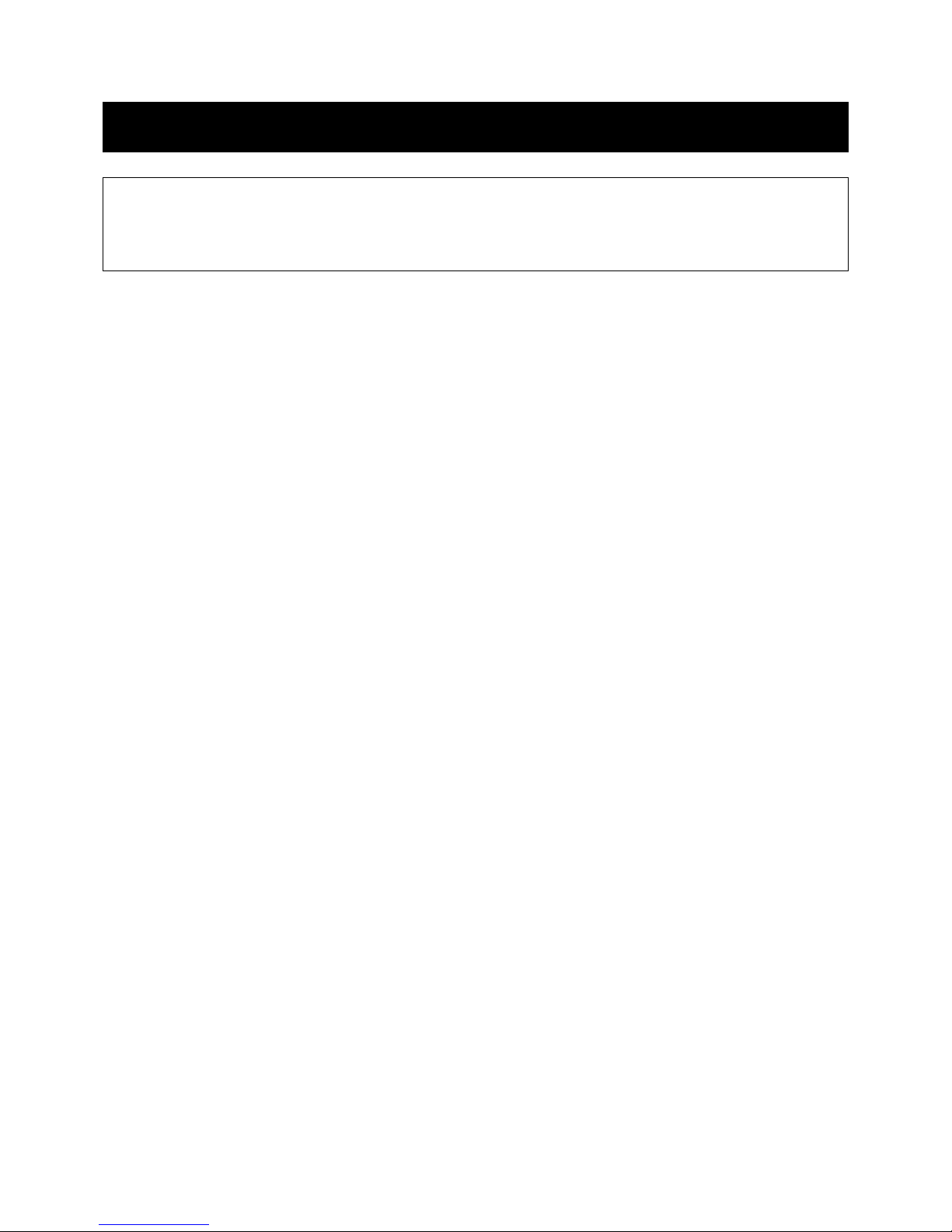

Fence............................................................................................................................................................ 8

Assembly....................................................................................................................................................... 8

Adjustment of Fence to Blade....................................................................................................................... 8

Adjustment of Rail to blade ........................................................................................................................... 8

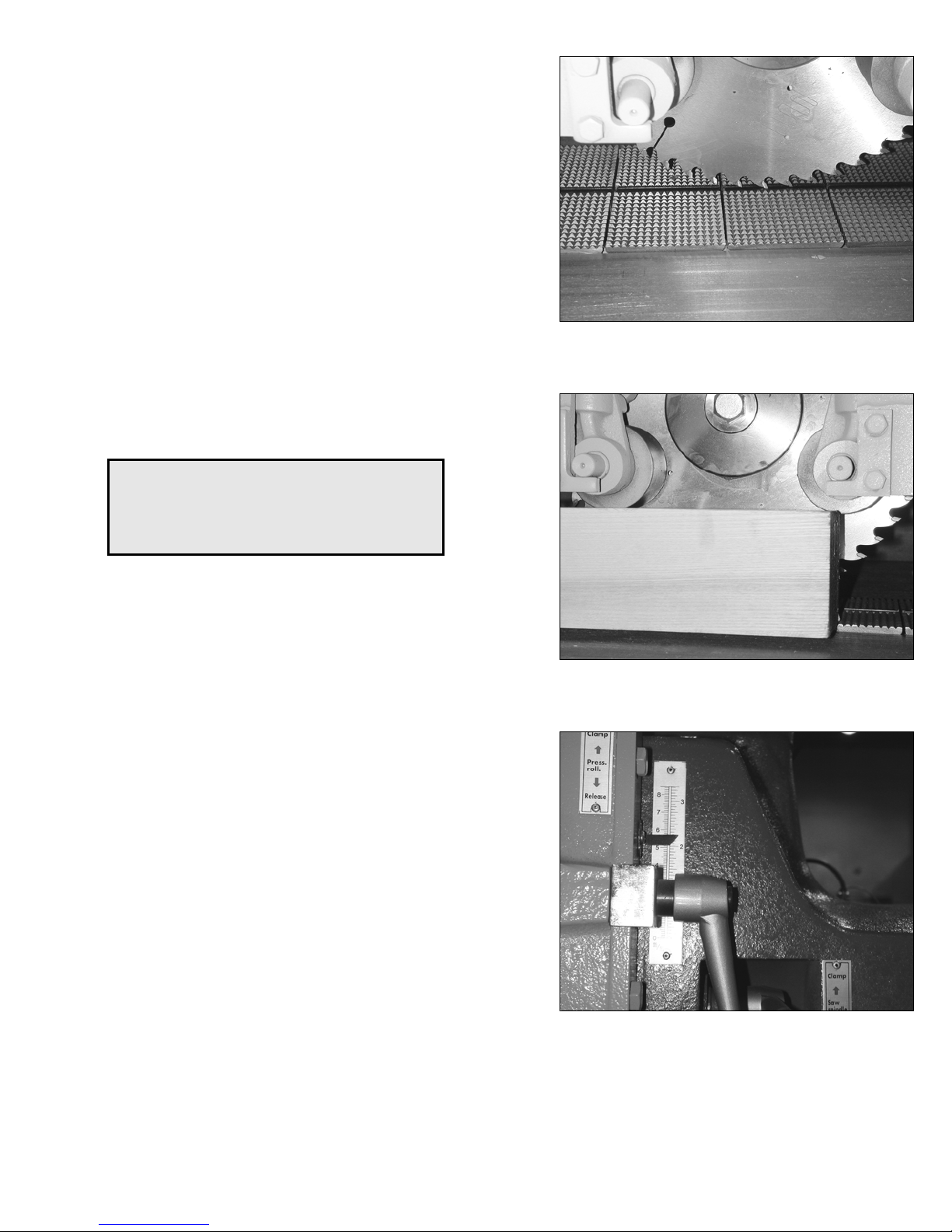

Saw Blade .................................................................................................................................................... 9

Choosing the Correct Saw Blade .................................................................................................................. 9

Replacing the Blade ...................................................................................................................................... 9

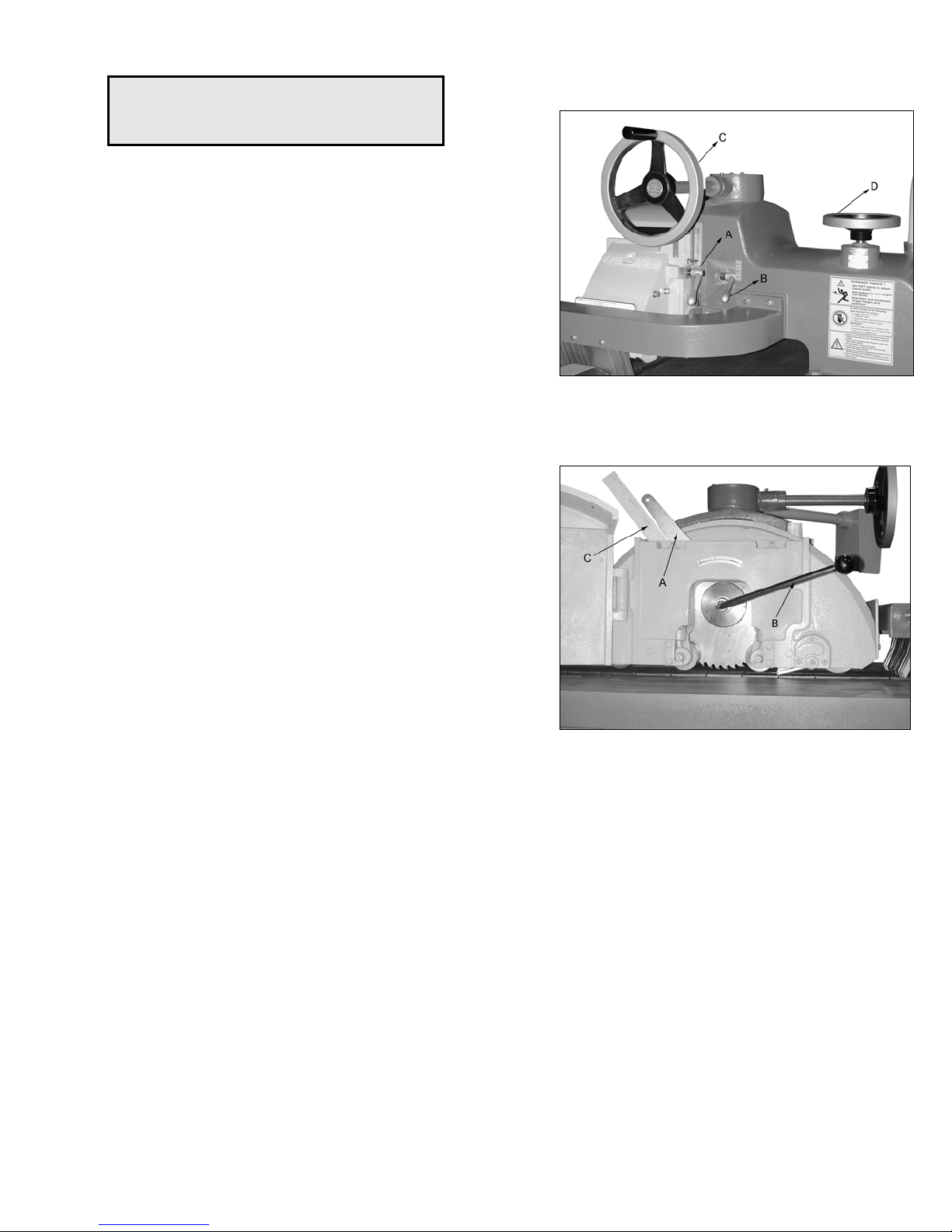

Setting the Saw Blade Height ..................................................................................................................... 10

Pressure Roller/Carriage.......................................................................................................................... 10

With Respect to Work Piece ....................................................................................................................... 10

Height Adjustment....................................................................................................................................... 10

Chain Oiler ................................................................................................................................................. 11

Adjusting the Interval/Duration.................................................................................................................... 11

Recommended Oil ...................................................................................................................................... 11

Operation ................................................................................................................................................... 12

Proper position of operator.......................................................................................................................... 12

Pre-start....................................................................................................................................................... 12

Start............................................................................................................................................................. 12

Feed Rate.................................................................................................................................................... 13

Maintenance .............................................................................................................................................. 13

Lubrication................................................................................................................................................... 13

Other ........................................................................................................................................................... 13

Troubleshooting .......................................................................................................................................... 14

Specifications

Model No................................................................................................................................................. 4910

Stock No........................................................................................................................................... 4910.001

Arbor Diameter (in.)....................................................................................................................................... 1

Blade Diameter (in.) .................................................................................................................................... 12

Blade Speed (RPM) ............................................................................................................................... 4,500

Feed Speed 3 Speed: .............................................................................................................. 45,60,70 FPM

Cutting Depth (in.) ...................................................................................................................................3-3/8

Maximum Ripping Width (in.)................................................................................................................. 13.75

Minimum Board Length (in.)........................................................................................................................ 14

Pressure Rollers............................................................................................................................................ 6

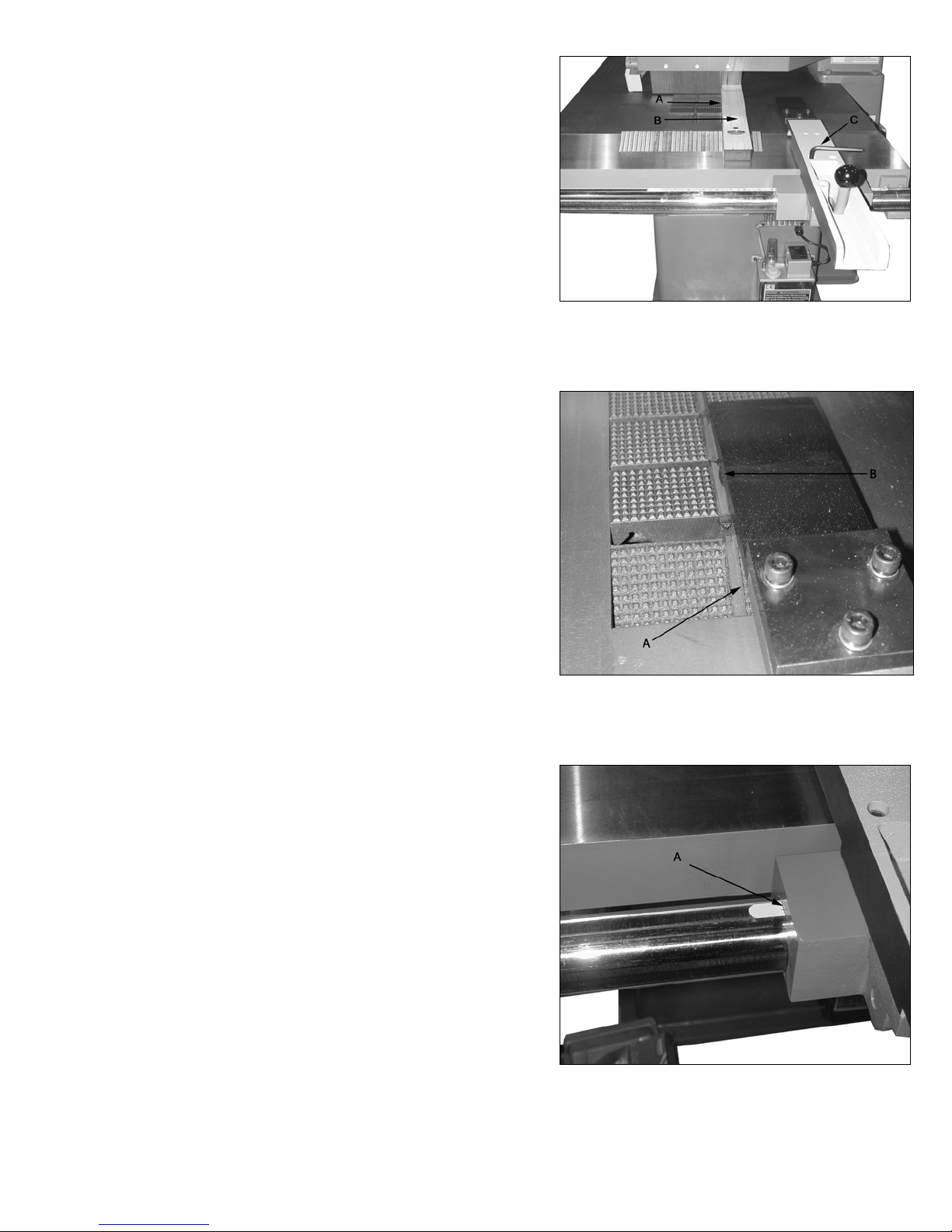

Anti-Kickback Device(s) ................................................................................................................................ 3

Table Size (W x L/in.).......................................................................................................................... 30 x 50

Table Height (in.)......................................................................................................................................... 30

Dust Collection Port (in.) ............................................................................................................................... 4

Feed Motor..................................................................................................................... 1HP, 3Ph, 220/440V

Controls..................................................................................................................................... 24V Magnetic

Motor ........................................................................................................................... 7.5HP, 3Ph, 220/440V

Shipping Dimension (L x W x H/in.) ............................................................................................ 45 x 59 x 58

Gross Weight (lbs.) ................................................................................................................................. 2310

CFM............................................................................................................ 400CFM at 4500FPM air velocity

5