Complete Teardown, Cleaning, and Reassembly of the Olympus BH2-5RE Modular Revolving Nosepiece Page 5 of 18

Revision 3

Introduction

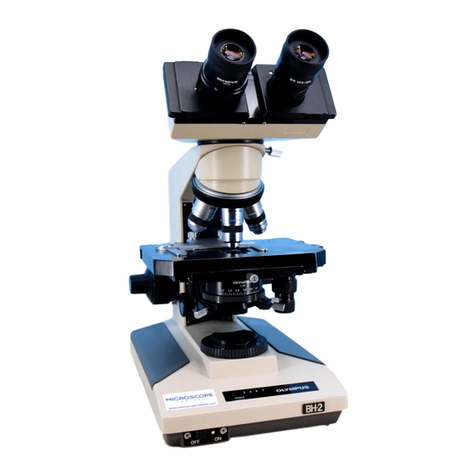

The microscopes in the Olympus BH-2 line have largely

been replaced in the professional and clinical world,

due to their advancing age and the lack of repair parts

from Olympus. A great many of these microscopes

were produced in their day, and because of this they

are readily available on the used market for very

reasonable prices. Thanks to their excellent build

quality and solid optical performance, these scopes are

now very popular with hobbyists, providing an

affordable, high-quality alternative to the Chinese-made

scopes prevalent today.

One issue that might be encountered when purchasing

either the BHS or BHT version of these microscopes is

that the grease in the BH2-5RE modular revolving

nosepiece assembly may be dried and gummy, resulting

in a stiff or gritty feel of the revolving nosepiece.

Another issue that may be encountered is with the

mechanical detents in the revolving nosepiece. After

many years of hard service, especially if the nosepiece

assembly has not been periodically lubricated

throughout its life, one or more of the detent stops may

be worn to the point where the detents are sloppy, and

the affected objectives do not maintain proper radial

indexing. At best, this is annoying to the operator, and

at worst can render the revolving nosepiece unusable.

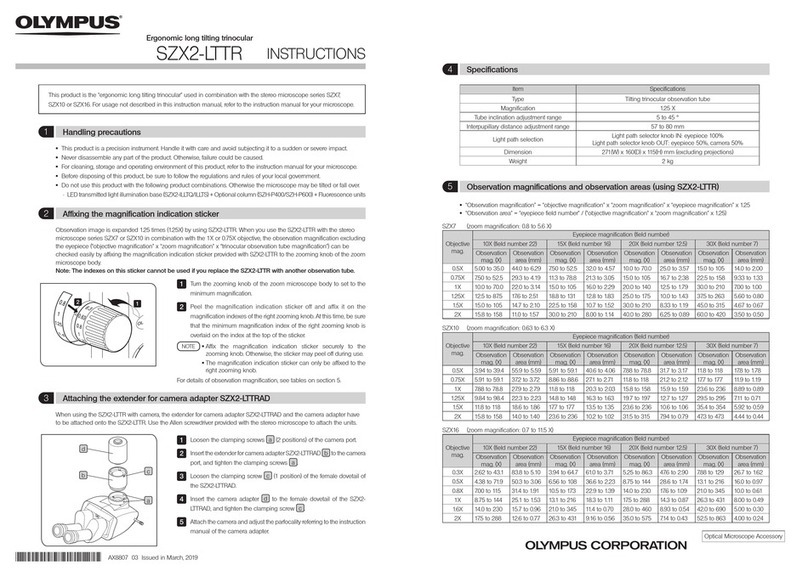

This document describes the complete teardown,

cleaning, lubrication, and reassembly of the BH2-5RE

(five-position) modular revolving nosepiece assembly as

used on a BHS or BHT microscope stand. Completion of

this maintenance procedure should restore the proper

feel to the nosepiece turret. Additionally, this

maintenance should reduce further wear of the

mechanical detent stops. Note that if the detents stops

are already excessively worn, there is no repair for this

other than the replacement of the revolving turret.

Scope of this Document

The procedures detailed in this document directly apply

to the BH2-5RE (five-position) revolving modular

nosepiece assembly used on the Olympus BHS, BHSP,

BHT, and BHTP microscope stands. This procedure is

also applicable the BH2-6RE (six-position) modular

revolving nosepiece assembly, due to its similarity with

the five-position nosepiece, although a separate

document exists in this series detailing the BH2-6RE.

Note that the original Olympus service literature did not

address the teardown and repair of the various

revolving nosepiece assemblies used on BH-2 stands, as

these were field-replaceable assemblies that were

considered unserviceable by Olympus.

Tools Needed

The following tools will be needed to complete the

teardown, cleaning, lubrication, and reassembly of the

BH2-5RE modular revolving nosepiece assembly.

•Center punch or nailset tool

•Electric heat gun (item T1 of Appendix 1)

•Lens-spanner tool (item T3 of Appendix 1)

•Screwdriver set, JIS (item T2 of Appendix 1)

A Few Words about JIS Screws

Screws with JIS heads are frequently found in much of

the older equipment designed and manufactured in

Japan. JIS screws look very much like standard Phillips

screws, but they differ in that JIS screws were designed

to not cam-out under torque, whereas Phillips screws

were designed to intentionally cam-out, as a means to

limit the torque applied to the fasteners. Because of

this crucial difference in the geometry of the two driver

types, JIS screws will be damaged by standard Phillips

drivers if too much torque is applied. JIS screws can

usually be identified by the presence of a single dot, or

by an “X”, stamped into one of the four quadrants of

the cross-point depression (see Figure 1).

Figure 1 –A typical JIS Screw

Supplies Needed

The following supplies will be needed to complete the

teardown, cleaning, lubrication, and reassembly of the

BH2-5RE modular revolving nosepiece assembly.

•Cleaning solvent (see recommendations below)

•Lubricant (see recommendations below)

•Adhesive, black (item S1 of Appendix 1)

Recommended Lubricant Types

Plastilube® Brake Grease or Mobilgrease28® grease

(item S2 of Appendix 1) are recommended for use in

the BH2-5RE modular revolving nosepiece assembly.

Both Plastilube® Brake Grease and Mobilgrease28® are

medium-consistency greases which will remain stable

and serviceable for many years to come.