Olympus K Operating instructions

Other Olympus Microscope manuals

Olympus

Olympus BX53-P User manual

Olympus

Olympus U-DA User manual

Olympus

Olympus SZ-III User manual

Olympus

Olympus BX-RFAA User manual

Olympus

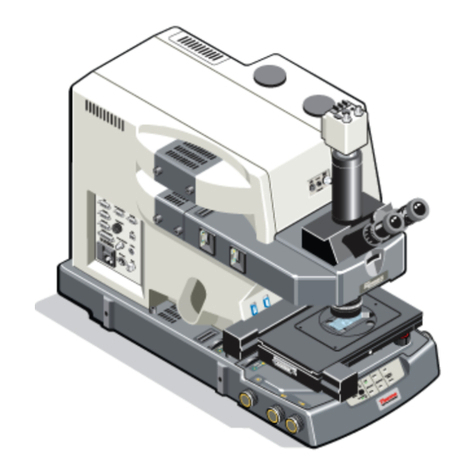

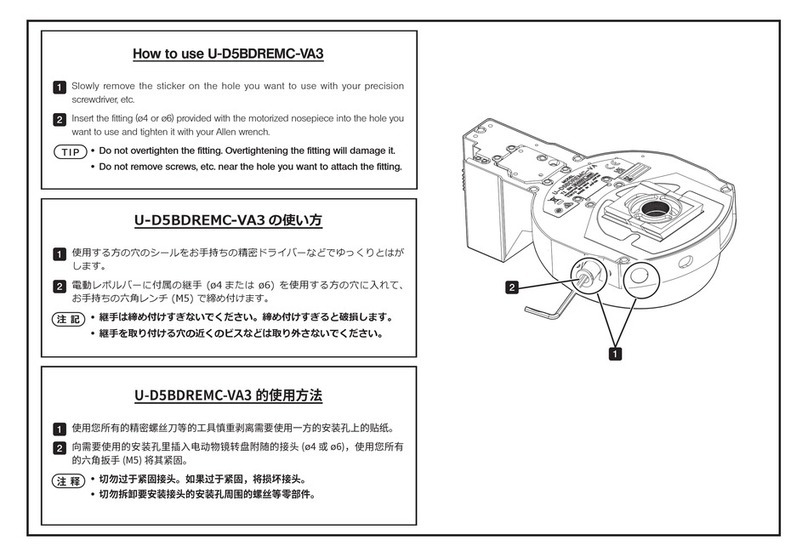

Olympus U-D5BDREMC-VA3 Operating instructions

Olympus

Olympus BX-URA2 User manual

Olympus

Olympus DP22 User manual

Olympus

Olympus BX60M User manual

Olympus

Olympus CX41 User manual

Olympus

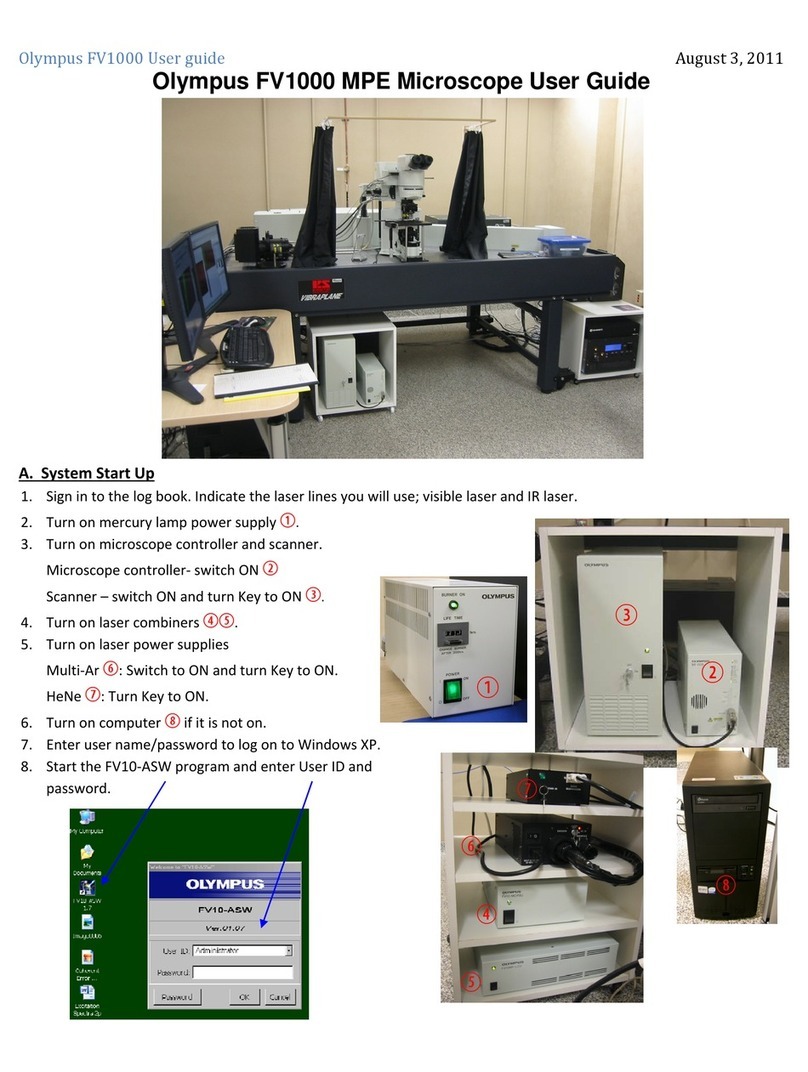

Olympus Fluoview FV1000 User manual

Olympus

Olympus VANOX Operating instructions

Olympus

Olympus IMT-2-11 User manual

Olympus

Olympus V60 User manual

Olympus

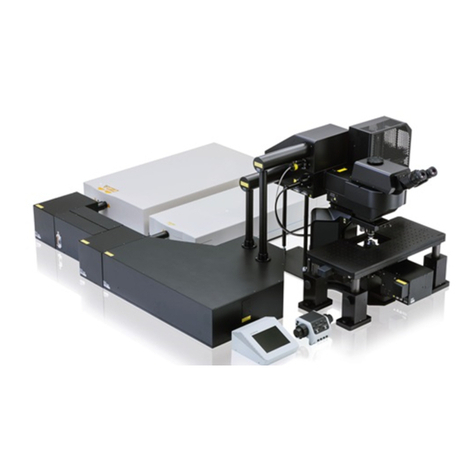

Olympus FLUOVIEW FVMPE-RS User manual

Olympus

Olympus SZ4045TR User manual

Olympus

Olympus Fluoview FV1000 Manual

Olympus

Olympus IX73 User manual

Olympus

Olympus DP21 User manual

Olympus

Olympus CX33 User manual

Olympus

Olympus U-D7RES User manual