BOLOGNA - FLY MOWER

9

Checks to be carried out on the tractor

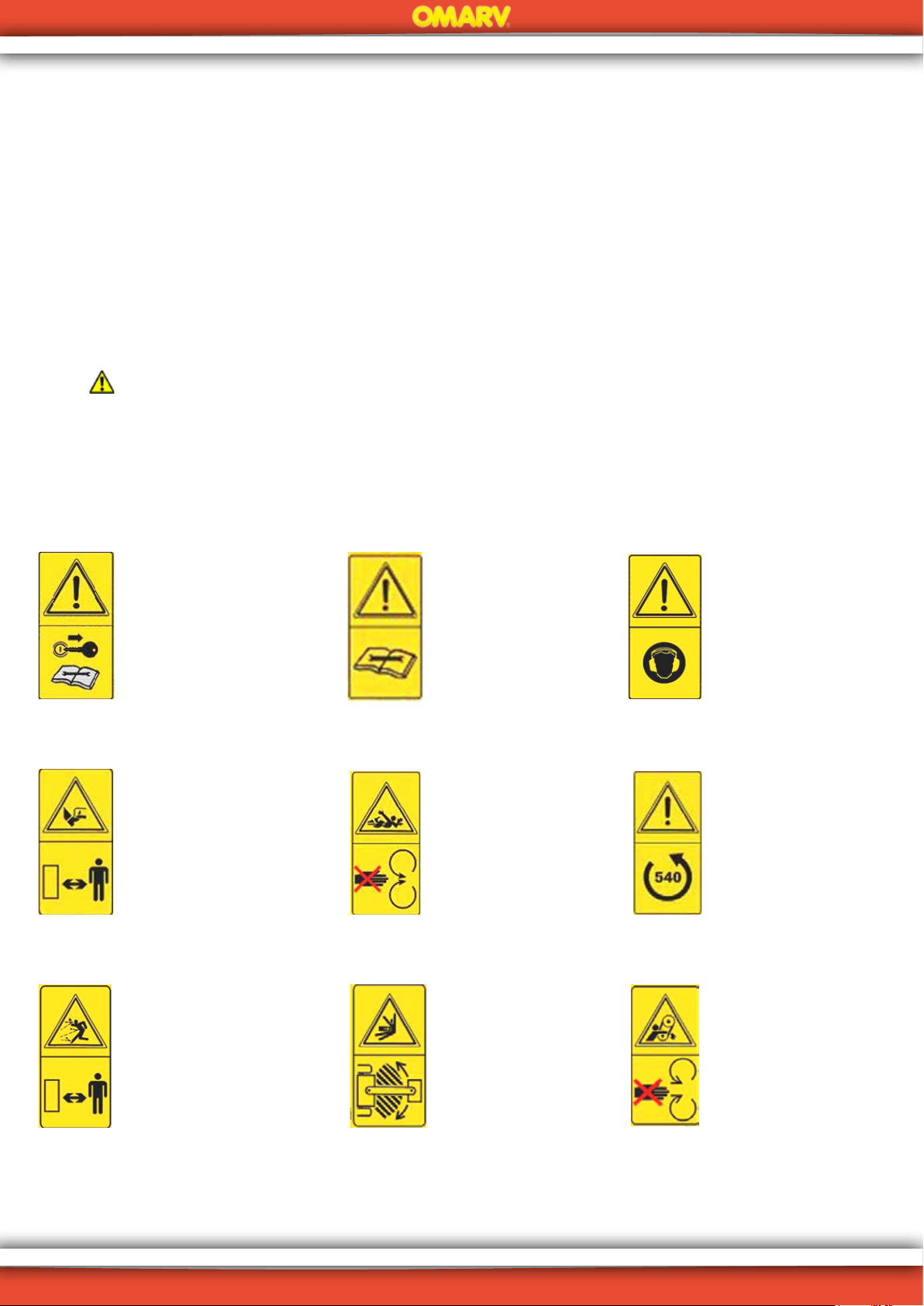

• Ensure that the drive shaft is tted correctly both on the power drive of the tractor and on the universal shaft of the machine.

• Check that the universal shaft is exposed for at last 1/3 third of the thread in its most extended position.

• Ensure that the guards are in perfect order, that they can be moved freely and that the xing chains are not under strain when

themachine is fully raised or lowered.

• Check that in the position of continuous working, universal shaft does not make an angle greater than 20° against the align-

ment of the power drive of the tractor.

• Ensure that the drive shaft does not touch the guard of the power drive of the tractor, the guards of the transmission shafts or

other parts of the machine.

• No operation regarding the drive shaft or the power drive should be made with the tractor motor running. The ignition key

should be taken out and shaft of the power drive should be in the off position.

• As soon as the shredding operation is nished the drive shaft must be disengaged from the power drive of the tractor and

returned to the support supplied for it.

• During use, maintenance, repairs, on the road, or during delivery of the machine the operator must wear safety footwear, safety

gloves, safety helmet and safety goggles for protection from falling objects or materials projected from the normal working of

the machine.

• The operator’s clothes should be as close tting as possible. Never use wide or oppy clothing.

• Never allow inexperienced or untrained person to use the machine. All use of the machine must be carried out slowly to avoid

carelessness that might create space that is free from any obstacles.

• Negligence or lack of attention could endanger your safety.

• Objects such as ropes, wire, cables, chains etc can hook onto the rotating elements of the cutting mechanism and be thrown

out at high speed causing very dangerous situations for the safety of the operator. You should avoid the blades coming into

contact with such object.

• If wire or similar materials become wrapped around the rotor try to free up the rotor (wearing safety gloves) with the help of

shears. Do not try to carry out the job by inverting the direction of rotation.

• Take great care during shredding on sloping ground. The machine could sway and make the tractor lose its balance, causing

serious injury or death to the operator. If this should happen do not remain in the vicinity and do not allow anyone to remain in

the rotation or oscillation zone of the machine.

• Check that there is nobody in the oscillation area of the machine before starting to rotor or the potential enacting of hydraulic

displacement.

• Do not allow anybody to climb onto the tractor or onto the machine. Do not carry out any operation if there is anyone nearby or

on the machine. Do not allow anyone to come near especially not children.

• Check the machine periodically inspecting the bolts in general, worn or broken parts, pinched or broken cables loose con-

nections or connections with too much play. Ensure that all the joint pins are adequately blocked. Always keep the machine

scrupulously clean and free form foreign objects. Clean immediately, any stains of oil or any other inammable material, to avoid

danger of re.

• Serious injury can be caused by neglecting maintenance.

• Do not continue to use the machine if a cutter is lost or so badly worn as to cause vibration. Consult the relevant section of the

manual for instruction on replacement procedures.

• Always replacement both the worn blade and the one opposite to it at the same time.