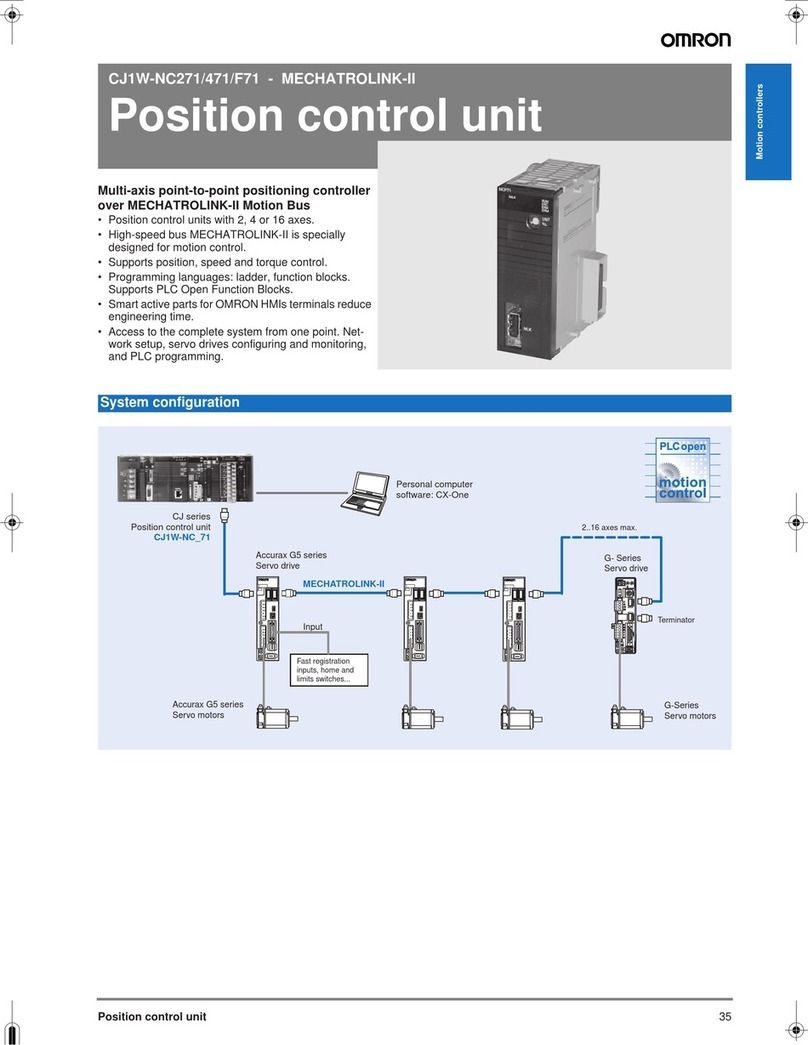

50 Motion controllers

Motion control unit

Specifications

Model CS1W-MCH71

Classification CS-series CPU bus unit

Applicable PLCs CS-series, (CS1@-CPU@@H)

Backplanes on which MC unit can be mounted CPU backplane or CS-series expansion I/O backplane

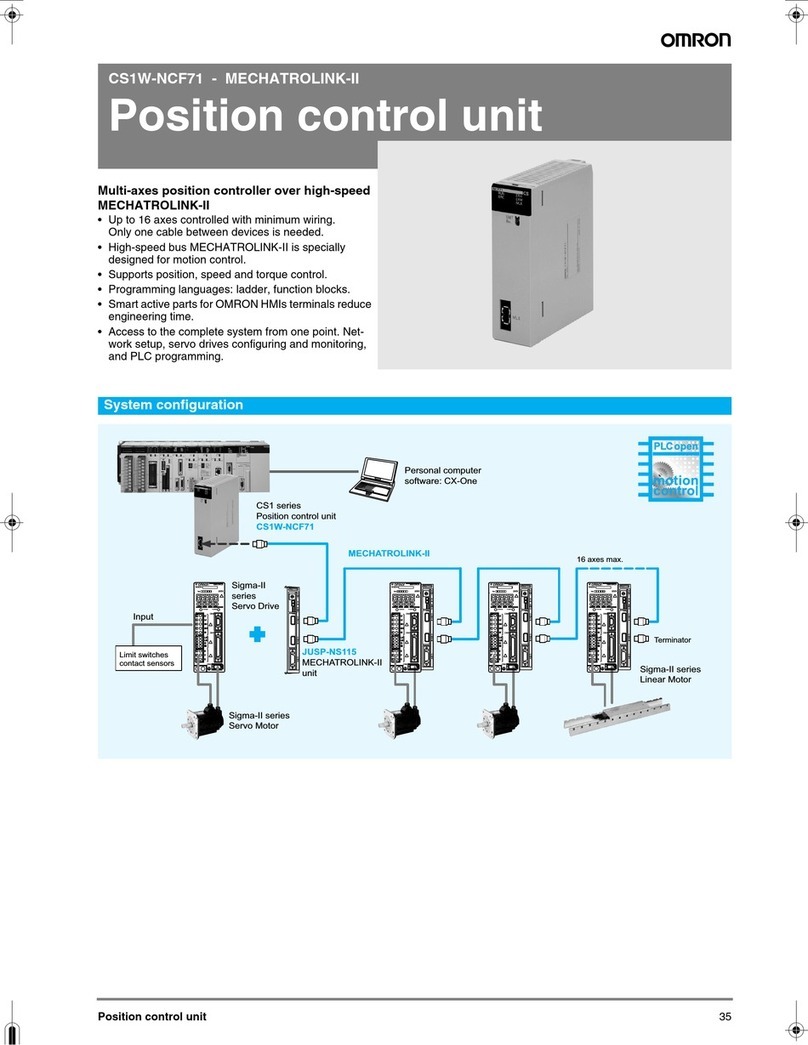

Control method MECHATROLINK-II (position, speed and torque control)

Controlled devices Sigma-II series servo drives (ver. 38 or later) with MECHATROLINK-II Interface, various I/O units and inverters V7, F7,

G7 with MECHATROLINK-II interface (for inverter version support contact your OMRON sales office)

Programming language BASIC type motion control language

Controlled axes 32 max, including 30 physical or virtual axes and 2 virtual axes

Operating modes RUN mode, CPU mode, Tool mode/system (depending on tool)

Automatic/manual mode Automatic mode: mode for executing programs in the unit

Manual mode: mode for executing commands from the CPU unit (via allocated words)

Minimum setting unit 1, 0.1, 0.01, 0.001, 0.0001 (unit: mm, inch, degree, pulse)

Maximum command value -2,147,483,648 to 2,147,483,647 pulses (32 bits with sign); infinite axis feed mode supported.

Example: 16,384 pulses/rev after multiplication, a minimum setting unit of 0.001 mm and 1 mm/rev would result

in -1,310,720,000 to 1,310,719,999 command units.

Control functions

by command from

CPU unit

Servo lock/unlock Locks and unlocks the servo driver.

Jogging Executes continuous feeding for each axis independently at selectable speed.

Origin search Determines the machine origin in the direction set in the system parameters.

Can be executed with an absolute encoder.

Absolute origin setting Sets the origin for when an absolute encoder is used. (Offset value: 32 bits [pulses] with sign)

Machine lock Stops the output of move commands to axes.

Single block Executes motion programs one block at a time.

Control functions by

motion program Positioning (PTP) Executes positioning independently for each axis at a specified speed or the speed system parameter.

(Simultaneous specification: up to eight axes/block, simultaneous execution: up to 32 blocks/unit)

Linear interpolation Executes linear interpolation for up to eight axes at a time at the specified interpolation feed speed.

(Simultaneous specification: up to eight axes/block, simultaneous execution: up to 32 blocks/system)

Circular interpolation Executes circular interpolation for two axes in either clockwise or counterclockwise at the specified interpolation

feed speed. Helical circular interpolation is also possible with single-axis linear interpolation added.

(Simultaneous specification: two or three axes/block, simultaneous execution: up to 16 blocks/system)

Other functions Origin searches, interrupt feeding, timed positioning, traverse positioning, independent electronic CAM, synchronized

electronic CAM, link operation, electronic gear, follow-up synchronization, speed reference, torque reference

Acceleration/deceleration curve,

acceleration/deceleration time Trapezoidal or S-curve, 60,000 ms max. (S-curve: constant 30,000 ms max.)

External I/O One port for MECHATROLINK-II servo communications, one deceleration stop input, two general inputs,

two general outputs

Feed rate Rapid, interpolation feed rate: 1 to 2,147,483,647 (command units/min)

Override 0.00% to 327.67% (setting unit: 0.01%; can be set for each axis or task.)

Motion

programs Number of tasks,

number of programs Up to 8 tasks and 256 programs/unit (8 parallel branches per task max.)

Program numbers 0000 to 0499 for main program; 0500 to 0999 for subroutine

Program capacity In motion program conversion, 8,000 blocks/unit max. (2 Mbytes); number of blocks: 800 per program

Data capacity Position data: 10,240 points/unit; cam data: 32 max.; 16,000 points/unit

Subroutine nesting Five levels max.

Start Programs in other tasks can be started from a program or from the PLC

Deceleration stop Decelerates to a stop regardless of the block.

Block stop Decelerates to a stop after the block being executed is ended.

Single block Executes the program one block at a time.

Data exchange

with CPU unit Unit BIT area Uses one unit number (25 words). Used for unit and tasks: 11 to 25 words (depending on the number of tasks)

Unit data area Uses one unit number (100 words). Used for unit and tasks: 32 to 74 words (depending on the number of tasks)

Axes BIT area Axes: 0 to 64 words (depending on the maximum axis number used). User configurable.

Axes data area Axes: 0 to 128 words (depending on the maximum axis number used). User configurable.

General purpose General I/O: 0 to 1,280 words (depending on the settings). User configurable.

Saving programs and data Memory card backup (in CPU unit, 100,000 times max.)

Self-diagnostic functions Watchdog, RAM check, etc.

Error detection functions Deceleration stop inputs, unit number errors, CPU errors, software limit errors, etc.

Error log function Read by IORD instruction from CPU unit.

Support software Microsoft Windows 2000 or NT 4.0 (Processor: Pentium, 100 MHz min., with at least 64 MB of memory)

External power supply voltage 24 VDC (21.6 to 26.4 VDC)

Internal current consumption 0.8 A or less for 5 VDC; 0.3 A or less for 24 VDC

Weight (not including connectors) 300 g max.

Y203-EN2-02-Katalog.book Seite 50 Mittwoch, 24. Mai 2006 2:22 14