Indicates a potentially hazardous situation which, if

not avoided, is likely to result in minor or moderate

injury or property damage. Read this manual

carefully before using the product.

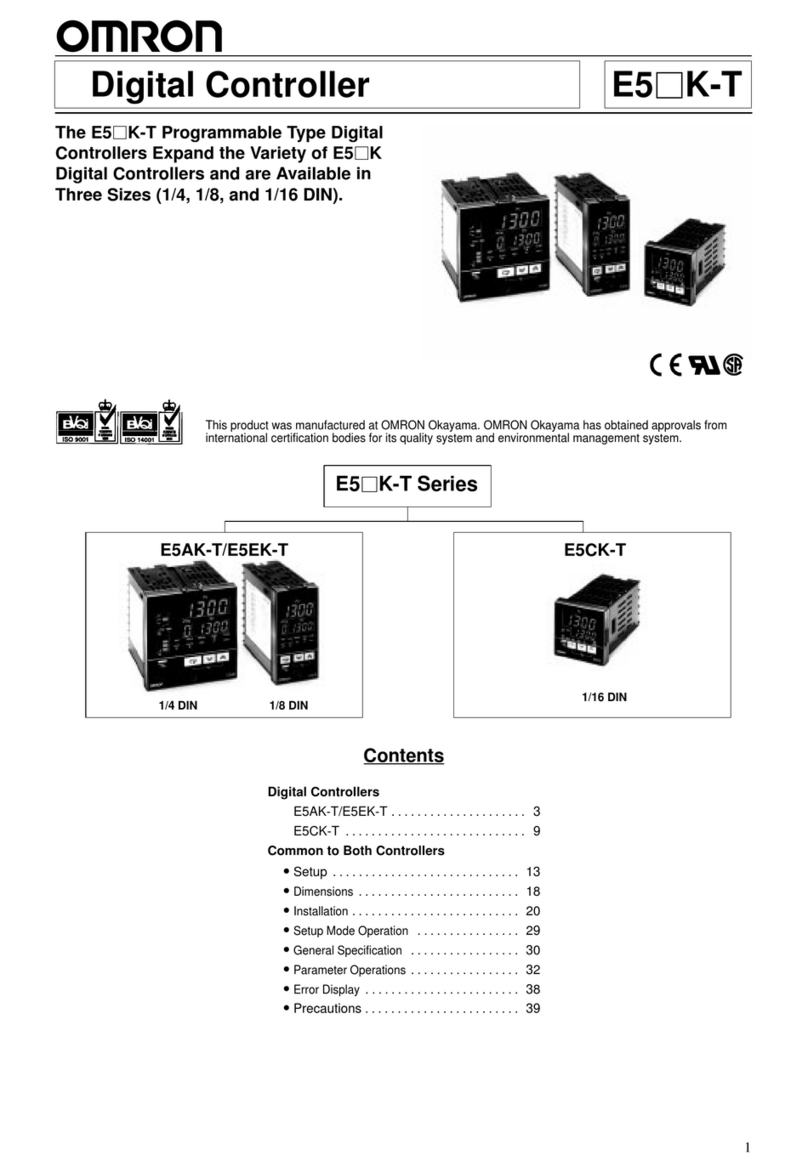

E5EC-T

Digital Controller

Precautions for Safe Use

Refer to the E5@C-T Digital Controllers User’s Manual (Cat. No. H185) for

detailed application procedures.

INSTRUCTION MANUAL

Thank you for purchasing the OMRON E5EC-T Digital Controller.

This manual describes the functions, performance, and

application methods needed for optimum use of the product.

Please observe the following items when using the product.

• This product is designed for use by qualified personnel with

a knowledge of electrical systems.

• Before using the product, thoroughly read and understand

this manual to ensure correct use.

• Keep this manual in a safe location so that it is available for

reference whenever required.

OMRON Corporation

©All Rights Reserved

Power supply voltage 100 to 240 VAC, 50/60 Hz or

24 VAC, 50/60 Hz / 24 VDC

Operating voltage range 85 to 110% of the rated voltage

Power consumption 8.7 VA max. (100 to 240 VAC)

5.5 VA max. (24 VAC)/3.2 W max. (24 VDC)

Indication accuracy Thermocouple:

(Ambient temperature: 23°C) (±0.3 % of indication value or ±1°C,

whichever is greater) ±1 digit max.

Platinum resistance thermometer:

(±0.2 % of indication value or ±0.8°C,

whichever is greater) ±1 digit max.

Analog input: ±0.2 % FS ±1 digit max.

Event input Output current: approx. 7 mA per contact.

Contact input ON:1 kΩmax., OFF: 100 kΩmin.

No-contact input ON: residual voltage 1.5 V max.,

OFF: leakage current 0.1 mA max.

Potentiometer input

Must be between 100 Ωand 10 kΩfor

maximum open position

Control output 1 Relay output :SPST-NO

250VAC, 5A (resistive load)

Electrical life of relay: 100,000 operations

Voltage output (for driving SSR):

12 VDC ±20%, 40 mA

Linear current output: 4 to 20 mA DC, 0 to 20mA DC

Load: 500 Ωmax.

Control output 2

Relay output: SPST-NO, 250 VAC, 5 A (resistive load)

Electrical life of relay: 100,000 operations

Control method 2-PID control

Auxiliary outputs Relay outputs:SPST-NO, 250 VAC,

2 A (resistive load),

Electrical life of relay: 100,000 operations

Transfer output 4 to 20 mA DC with load of 500 Ωmax.

1 to 5 VDC with load of 1 kΩmin.

Ambient temperature -10 to 55°C (Avoid freezing or condensation)

Ambient humidity 25 to 85%

Storage temperature -25 to 65°C (Avoid freezing or condensation)

Altitude Max. 2,000m

Recommended fuse

T2A, 250 VAC, time-lag, low-breaking capacity

Weight Approx. 210 g (Digital Controller only)

Degree of protection Front panel: IP66

Rear case: IP20, Terminal section: IP00

Installation environment Installation category II, pollution degree 2

(as per IEC61010-1)

Memory protection

Non-volatile memory (No. of write operations: 1,000,000)

Temporary overvoltage Short term: 1200 V+ power supply voltage

Long term: 250 V+ power supply voltage

CAUTION

EN

Safety Precautions

Key to Warning Symbols

When an error has occurred, the No.1 display shows the error code. Take necessary measure

according to the error code, referring the table below.

Check the setting of the Input Type parameter, check the input wiring,

and check for broken or shorts in the temperature sensor.

Turn the power OFF then back ON again. If the display remains the same, the

controller must be repaired. If the display is restored to normal, then a probable

cause can be external noise affecting the control system. Check for external noise.

After the check of Input error, turn the power OFF then back ON again. If

the display remains the same, the controller must be repaired. If the display

is restored to normal, then a probable cause can be external noise affecting

the control system. Check for external noise.

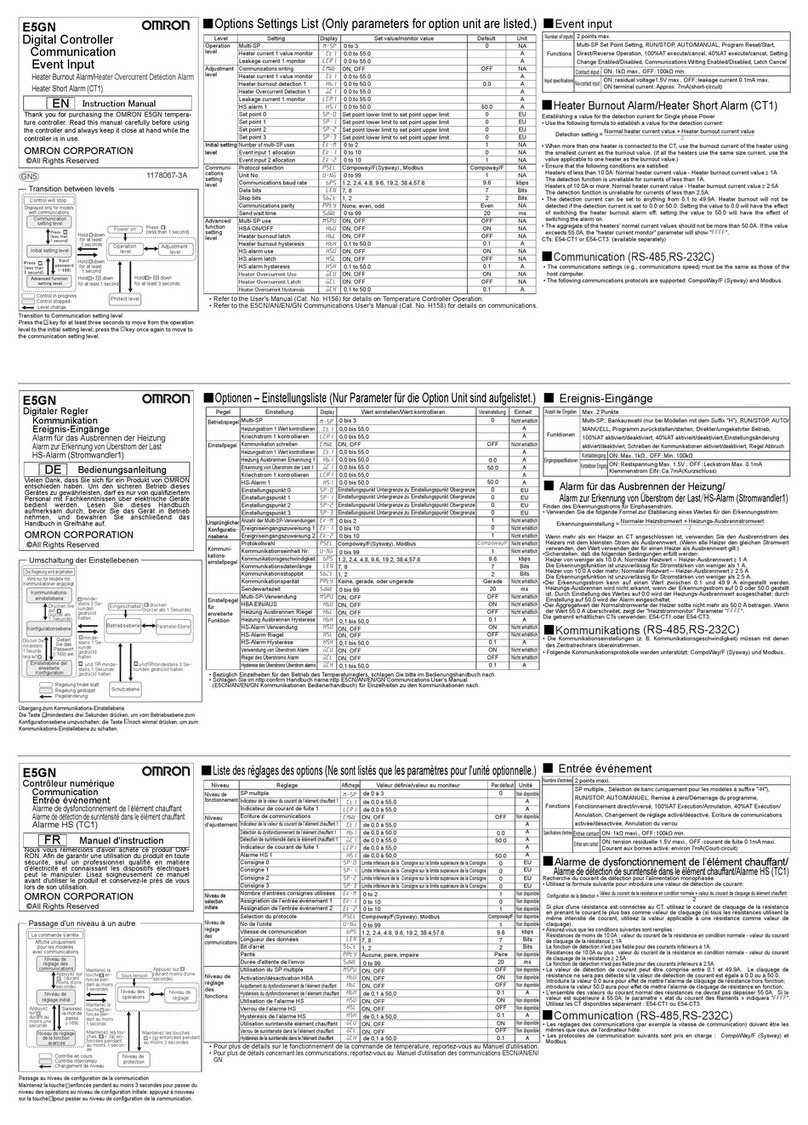

No.1 display Meaning

A/D converter

error

*

Memory error

Input error

*

s.err (S. Err)

e111 (E111)

Action

OFF

Alarm

Status at error

OFF

OFF

Operates as above

the upper limit.

OFF

OFF

e333 (E333)

Error Display (troubleshooting)

Specifications

Operation Menu

Alarms

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp The Netherlands

Phone 31-2356-81-300

FAX 31-2356-81-388

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg, IL 60173-5302 U.S.A

Phone 1-847-843-7900

FAX 1-847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark, Singapore 119967

Phone 65-6835-3011

FAX 65-6835-2711

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku, Kyoto 600-8530 JAPAN

• The default alarm type is "2".

*1: Upper and lower limits can be set for parameters 1, 4 and 5 to provide for

different types of alarm. These are indicated by the letter "L" and "H".

*2: Refer to the tables above for details of input types and alarm types.

*3:

Only the value set to the ins: Temperature Input Shift parameter is applied to the

entire temperature input range. When the process value is 200°C, the process value is

treated as 201.2°C after input shift if the input shift value is set to 1.2°C. The process

value is treated as 198.8°C after input shift if the input shift value is set to -1.2°C.

*4: Operation is stopped when moved to the initial setting level.

(control/alarm are both stopped.)

* The grayed-out setting items are not displayed for some models and some

settings of other setting items.

Adjustment Level

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which apply to the

combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request, Omron will provide

applicable third party certification documents identifying ratings and limitations of use which apply to the Product. This

information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the

end product, machine, system, or other application or use. Buyer shall be solely responsible for determining

appropriateness of the particular Product with respect to Buyer’s application, product or system. Buyer shall take

application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY

WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND

THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

Suitability for Use

Dimensions (mm)

144

19

60

4

(64)

011

Dimensions

Installation

Individual mounting (mm)

Side-by-side mounting (mm)

• Insert the main unit through the mounting hole in the panel

(1-8 mm thickness). Insert the mounting brackets (supplied)

into the fixing slots located on the top and bottom of the rear

case.

• Tighten the two mounting screws on the top and bottom of

the adapter to keep them balanced, and finally tighten them

to a torque of between 0.29 and 0.39 N·m.

• When more than one machine is installed, make sure that the

ambient temperature does not exceed the specified limit.

Waterproofing is

impossible with

side-by-side installation.

When waterproofing is

required, fit watertight

packing on the

backside of front panel.

nim0

2

1

45

29

+ 0.6

0

8.0

+

0

(48 x number of units–2.5) + 1.0

0

29 8.0+

0

Sold Separately

• Terminal cover: (E53-COV24)

• USB-Serial Conversion Cable (E58-CIFQ2)

• Conversion Cable (E58-CIFQ2-E)

In the pack:

• Main unit

• Instruction manual

• Watertight packing (Y92S-P9):

• Two adapters (Y92F-51):

• Front-panel Setup Tool port cover (Y92S-P7):

* Do not remove the terminal block. Doing so may result in failure or malfunction.

* Setup Tool ports are provided on the top and front of the Digital Controller. Use these ports to connect a personal

computer to the Digital Controller when using the Setup Tool. The E58-CIFQ2 USB-Serial Conversion Cable is

required to connect to the top-panel port. The E58-CIFQ2-E USB-Serial Conversion Cable is required to connect to

the front-panel port. (Do not use the product with the USB-Serial Conversion Cable left permanently connected.)

Refer to the instruction manual provided with the USB-Serial Conversion Cable for details on connection methods.

* If the front-panel port cover is lost or damaged, order it separately. The Waterproof Packing should be periodically

replaced because it may deteriorate, shrink, or harden depending on the operating environment.

Names of Parts on Front Panel

Solderless terminal size: M3

Wiring

• Up and Down keys

Each press of Ukey increments or advances

the values displayed on the No.2 display.

Each press of Dkey decrements or returns the

values displayed on the No.2 display.

• No.1 display

Process value or set data type

• No.2 display

Set point, set data read-out value or changed

input value

• Mode key

Press this key to change the contents of the display.

Press this button for 1 second or longer for reverse scroll.

• Hold the Mkey and the Dkey together for at least 1 second to switch Run/Reset.

•

Hold the Okey and the Mkey together for at least 3 seconds to switch to protect level.

• No. 3 display

Program No., segment No,. segment remaining

time or MV (valve opening)

• Front-panel Setup Tool port

This port is used to connect the

Controller to a computer to use the

Setup Tool.

• Level key

Use this key to change levels.

• °C / °F : temperature unit

Either Cor Fis displayed when the

displayed value is a temperature.

• Shift key (PF key)

Pressing this key operates the function that

has been set on "PF Setting" of the

advanced function setting level. The default

PF Setting parameter is for shifting the digit.

Operation indicators

•TUNE:

Lit during AT (auto-tuning).

•CMW:

Lit when communications writing is

enabled and not lit when it is disabled.

•

SUB1 to 4: Auxiliary outputs 1 to

4 indicators

•

FSP:

Lit when the Fixed SP mode is

ON.

Program status (the direction of

change in the SP)

•

OUT1 to 2: Control outputs 1 to

2 indicators

Lit for other than 0% output for

linear current output.

•

RST:

Lit during a program reset.

•

MANU:

Lit during Manual Mode.

•

HOLD:

Lit during a program hold.

•

WAIT:

Lit during a program wait.

• :

Lit when Setting Change Protect is

ON (disables the Up and Down Keys).

•

:

48

96

Be sure to observe the following precautions to prevent operation failure, malfunction, or adverse effects on the

performance and functions of the product. Not doing so may occasionally result in unexpected events.

Use the product within specifications.

(1) The product is designed for indoor use only. Do not use the product outdoors. Do not use or store the product

in any of the following locations.

•Places directly subject to heat radiated from heating equipment.

•Places subject to splashing liquid or oil atmosphere.

•Places subject to direct sunlight.

•Places subject to dust or corrosive gas (in particular, sulfide gas and ammonia gas).

•Places subject to intense temperature change.

•Places subject to icing and condensation.

•Places subject to vibration and large shocks.

(2) Use/store within the rated temperature and humidity ranges. Provide forced-cooling if required.

(3)

To allow heat to escape, do not block the area around the product. Do not block the ventilation holes on the product.

(4) Be sure to wire properly with correct polarity of terminals.

(5) Use the specified size of crimped terminals (M3, width 5.8 mm or less) for wiring. To connect bare wires to the

terminal block, use copper braided or solid wires with a gage of AWG24 to AWG18 (equal to cross- sectional

area of 0.205 to 0.8231 mm2). (The stripping length is 6 to 8 mm.) Up to two wires of same size and type, or

two crimped terminals can be inserted into a single terminal.

(6) Do not wire the terminals which are not used.

(7) Allow as much space as possible between the controller and devices that generate a powerful high- frequency

or surge. Separate the high-voltage or large-current power lines from other lines, and avoid parallel or

common wiring with the power lines when you are wiring to the terminals.

(8) Use this product within the rated load and power supply.

(9) Make sure that the rated voltage is attained within two seconds of turning ON the power using a switch or relay

contact. If the voltage is applied gradually, the power may not be reset or output malfunctions may occur.

(10) Make sure that the Digital Controller has 30 minutes or more to warm up after turning ON the power before

starting actual control operations to ensure the correct temperature display.

(11) A switch or circuit breaker should be provided close to this unit. The switch or circuit breaker should be within

easy reach of the operator, and must be marked as a disconnecting means for this unit.

(12) Wipe off any dirt from the Digital Controller with a soft dry cloth. Never use thinners, benzine, alcohol, or any

cleaners that contain these or other organic solvents. Deformation or discoloration may occur.

(13) Design system (control panel, etc) considering the 2 second of delay that the controller’s output to be set after

power ON.

(14) The output will turn OFF when you move to the Initial Setting Level. Take this into consideration when

performing control.

(15) The number of non-volatile memory write operations is limited. Therefore, use RAM write mode when

frequently overwriting data during communications or other operations.

(16) When disassembling the Temperature Controller for disposal, use suitable tools.

(17) Do not connect cables to both the front-panel Setup Tool port and the top-panel Setup Tool port at the same

time. The Digital Controller may be damaged or may malfunction.

(18) Do not exceed the communications distance that is given in the specifications and use the specified

communications cable. Refer to the E5@C-T Digital Controllers User’s Manual (Cat. No. H185) for the

communications distance and cable specifications.

(19) Do not turn the power supply to the Digital Controller ON or OFF while the USB-Serial Conversion Cable is

connected. The Digital Controller may malfunction.

(20) The terminals can reach temperatures of up to 75°C.

Control output

CAUTION

Minor injury due to electric shock may occasionally occur.

Do not touch the terminals while power is being supplied.

Electric shock, fire, or malfunction may occasionally occur. Do not allow metal objects, conductors,

cuttings from installation work, or moisture to enter the Digital Controller, the Setup Tool ports, or

between the pins on the connectors on the Setup Tool cable. Attach the cover to the front-panel

Setup Tool port whenever you are not using it to prevent foreign objects from entering the port.

Do not use the product where subject to flammable or explosive gas. Otherwise, minor injury from

explosion may occasionally occur.

Never disassemble, modify, or repair the product or touch any of the internal parts. Minor electric

shock, fire, or malfunction may occasionally occur.

CAUTION - Risk of Fire and Electric Shock

a) This product is UL listed as Open Type Process Control Equipment. It must be mounted in an enclosure that

does not allow fire to escape externally.

b) More than one disconnect switch may be required to de-energize the equipment before servicing.

c) Signal inputs are SELV, limited energy.

d) Caution: To reduce the risk of fire or electric shock, do not interconnect the outputs of different Class 2 circuits.

If the output relays are used past their life expectancy, contact fusing or burning may occasionally occur.

Always consider the application conditions and use the output relays within their rated load and

electrical life expectancy. The life expectancy of output relays varies considerably with the output load

and switching conditions.

Loose screws may occasionally result in fire. Tighten the terminal screws to the specified torque of 0.43

to 0.58 N•m.

Set the parameters of the product so that they are suitable for the system being controlled. If they are

not suitable, unexpected operation may occasionally result in property damage or accidents.

A malfunction in the Digital Controller may occasionally make control operations impossible or prevent

alarm outputs, resulting in property damage. To maintain safety in the event of malfunction of the Digital

Controller, take appropriate safety measures, such as installing a monitoring device on a separate line.

Warning Symbols

* Error shown only for "Process value / Set point". Not shown for other status.

If the input value exceeds the display limit (-1999 to 9999), though it is within the control range, [[[[ will be displayed

under -1999 and ]]]] above 9999. Under these conditions, control output and alarm output will operate normally. Refer

to the E5@C-T Digital Controllers User’s Manual (Cat. No. H185) for the controllable ranges.

stb

0.00

p

8.0

i

233

wt-b

off

ins

0.0

M

M

M

M

M

d

40

M

at

off

cmwt

off

spmd

psp

fsp

0

M

M

M

M

ol-h

100.0

ol-l

0.0

db

2.0

oc-h

0.8

M

M

of-r

50.0

M

M

plcm

1234

M

ct1

0.0

hb1

0.0

M

M

Communications Writing

SP Mode

AT Execute / Cancel

100%AT Execute at-2

40%AT Execute at-1

Heater Current 1 to 2

Value Monitor

(Unit: A)

Heater Burnout

Detection 1 to 2

(Unit: A)

Fixed SP

PV

Input Shift *3

Wait Band

Integral Time

(Unit: Seconds)

Proportional

Band

Standby Time

Derivative Time

(Unit: Seconds)

Adjustment level is for entering set values and shift values for control.

Manual Reset Value

Clears the offset

during P or PD control.

MV Upper Limit

MV Lower Limit

Communications

Monitor

Opening/Closing

Hysteresis

Position Proportional

Dead Band

orl

0.0

M

MV Change

Rate Limit

Operation stopped.

(Control/alarm are both stopped.)

*4

Initial Setting Level

Use the following ranges for scaling: -1999

to 9999, -199.9 to 999.9, -19.99 to 99.99,

-1.999 to 9.999

Analog

input type

Current input

Voltage input

Check the wiring before turning ON the power supply.

*1

*1

*1

Alarm type

Vary with

"L", "H" values

Vary with

"L", "H" values

Vary with

"L", "H" values

No alarm function Output off

Deviation upper/lower limit

standby sequence ON

Absolute value upper limit

Absolute value lower limit

Absolute value upper limit

standby sequence ON

Absolute value lower limit

standby sequence ON

LBA (only for alarm 1)

Deviation lower limit

standby sequence ON

Deviation upper limit

standby sequence ON

Deviation upper/lower range

Deviation upper limit

Deviation upper/lower limit

Deviation lower limit

Alarm output function

Positive alarm value (X)

Negative alarm value (X)

Setting

PV Change Rate Alarm

X

ON

OFF SP

X

ON

OFF SP

ON

OFF SP

X

X

ON

OFF SP

LH

ON

OFF SP

X

ON

OFF SP

X

ON

OFF SP

X

ON

OFF 0

ON

OFF

X

0

X

ON

OFF 0

X

ON

OFF 0

ON

OFF

X

0

X

ON

OFF 0

X

ON

OFF 0

X

ON

OFF 0

X

ON

OFF 0

X

ON

OFF 0

ON

OFF

X

0

ON

OFF

X

0

ON

OFF

X

0

ON

OFF

X

0

LH

ON

OFF SP

SP

ON

OFF

X

ON

OFF

X

0

1

0

2

3

4

5

6

7

8

9

SP absolute value upper limit

SP absolute value lower limit

14

15

MV absolute value upper limit

MV absolute value lower limit

16

17

10

11

12

13

SP

X

ON

OFF

ON

OFF

X

0

POWER ON

4 to 20mA

0 to 20mA

1 to 5V

0 to 5V

0 to 10V

25

26

27

28

29

Setting range

Input type Input

Pt100

JPt100

Thermocouple

Infrared

Thermosensor

ES1B

K

J

T

E

L

U

N

R

S

B

W

PL II

Setting

10 to 70°C

60 to 120°C

115 to 165°C

140 to 260°C

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Input Type

-200 to 850

-199.9 to 500.0

0.0 to 100.0

-199.9 to 500.0

0.0 to 100.0

-200 to 1300

-20.0 to 500.0

-100 to 850

-20.0 to 400.0

-200 to 400

-199.9 to 400.0

-200 to 600

-100 to 850

-200 to 400

-199.9 to 400.0

-200 to 1300

0 to 1700

0 to 1700

100 to 1800

0 to 2300

0 to 1300

0 to 90

0 to 120

0 to 165

0 to 260

-300 to 1500

-199.9 to 900.0

0.0 to 210.0

-199.9 to 900.0

0.0 to 210.0

-300 to 2300

0.0 to 900.0

-100 to 1500

0.0 to 750.0

-300 to 700

-199.9 to 700.0

-300 to 1100

-100 to 1500

-300 to 700

-199.9 to 700.0

-300 to 2300

0 to 3000

0 to 3000

300 to 3200

0 to 3200

0 to 2300

0 to 190

0 to 240

0 to 320

0 to 500

Platinum

resistance

thermometer

Temperature inputs

*The default is“5”.

*s.err will be displayed when a platinum resistance thermometer is mistakenly connected while

input type is not set for it. To clear the s.err display, correct the wiring and cycle the power supply.

Operation Level

°C °F

LH

ON

OFF

SP

styp

ramp

sp

0

M

pr

0

M

time

0.00

M

rpt

0

link

end

M

M

M

pid

1

M

MM

d.seg

end

U

Eend 0 to 7

s-no

8

M

M

7

6

5

4

3

2

1

d.prg

0

D

7

6

5

4

3

2

1

d.seg

0

al1l

0

M

al-1

0

al1h

0

M

M

of1

0.00

M

ts1s

0

on1

0.00

M

M

25

0

U

D

U

D

d.pid

1

M

Refer to the E5@C-T Digital Controllers User’s Manual (Cat. No. H185) for information on

the Advanced Function Setting Level, Manual Control Level, and other functions.

Refer to the E5@C-T Digital Controllers Communications Manual (Cat. No. H186) for

information on communications.

Other functions

Protect Level

Hold Oand Mkeys

down for at least

3 seconds

Program Setting Level

PID Setting Level

Press O

(less than 1 second)

Press O

(less than 1 second)

Press O(less than 1 second) Press O(less than 1 second)

PID Set

No.

Alarm

Value 1 to 4

Alarm

Upper

Limit 1 to 4

Alarm

Lower

Limit 1 to 4

Number of

Segments Used

Display Program

Selection

Display Segment Selection,

END or 0 to Number of

Segments −1

Segment

n Format

(Only at

Slope Setting)

Segment

n SP

Segment n Slope

(Only at Slope

Setting)

Segment

n Time

Time Signal 1 to 2

Set Segment

Time Signal 1 to 2

ON Time

Time Signal 1 to 2

OFF Time

In this level, the SPs and times

are input for the programs.

For other information, refer to the E5@C-T

Digital Controllers User’s Manual

(Cat. No. H185).

Program

Link

Destination

Program

Repetitions

Press Ufor at least 1 sec.

in Program SP Mode

Display PID Selection

(The No.3 display has

been omitted.)

PV/SP (1) (2) of

Operation

Level

Do not connect anything to the terminals that are shaded gray.

2

(no polarity)

Input Power Supply

100 to 240 VAC

1

24 VAC/DC

Sensor Temperature/Analog Input

V

−

23

V24

+

22

TC

22

+

−

mA

−

+

23

22

23

24

Pt I

24

22

23

24

080

Communications, four event inputs,

two CTs, and transfer output

082

Communications, four event inputs, and

transfer output

Control Outputs

One relay One voltage

(for driving SSR)

Two relays

One linear current

RX

PR

QX

CX

070

Four event inputs

and one CT

068

Communications, two event

inputs, and one CT

Options

064

Communications

and two event inputs

Auxiliary Outputs

Auxiliary outputs 1 to 4

Connections

(The applicability of the electric terminals varies with the type of machine.)

* When complying with EMC standards, the line connecting the sensor must be 30 m or less.

If the cable length exceeds 30 m, compliance with EMC standards will not be possible.

A

B

B

3

4

5

6

R

OUT1 +

−

3

4

5

6

Q

OUT1

+

−

3

4

5

6

C

OUT1 3

4

5

6R

R

OUT1

OUT2

Potentiometer

input

19

20

21

C

W

O

The E5EC-T is set for a K thermocouple (input type of 5) by default. If a different sensor

is used, an input error (s.err) will occur. Check the setting of the Input Type parameter.

+

+

-

19

20

21

13

14

15

17

18

16

EV1

EV2

B(+)

A(-)

RS-485

+

+

-

21

19

20

17

18

15

16

13

14

EV1

EV2

B(+)

A(-)

RS-485

CT1

+

+

-

+

+

-

21

19

20

16

17

18

13

14

15

EV1

EV2

EV3

EV4

CT1

065

Four event inputs

+

+

-

+

+

-

19

20

16

17

18

13

14

15

EV1

EV2

EV3

EV4

33

31

32

30

29

28

21-

19

20

++

+

+

-15

16

17

18

13

14

V

I

EV5

EV6

B(+)

A(-)

RS-485

Transfer

output

+

+

-

EV1

EV2

COM

CT1

CT2

+

+

-

+

+

-

28

29

30

32

31

33

13

14

15

16

17

18

19

20

21

+

-

+

V

I

EV1

EV2

EV5

EV6

B(+)

A(-)

RS-485

Transfer

output

7

8

11

12

9

10 Auxiliary output 2

Auxiliary output 1

Auxiliary output 4

Auxiliary output 3

Control outputs Options

E5EC T M

1

2

Relay

250 VAC, 5 A

(resistive load)

Linear current

0 to 20 mA DC

Voltage (for driving SSR)

12 VDC, 40 mA

Load: 500 Ωmax.

4 to 20 mA DC

Relay

250 VAC, 5A (resistive load)

Control output 1 Auxiliary outputControl output 2

Relay

250 VAC, 2 A

(resistive load)

21

Restricts which settings can be displayed or

changed, and restricts change by key operation.

oapt

0

pmsk

on

icpt

1

wtpt

off

pfpt

off

M

M

M

M

M

Operation /

Adjustment

Protect

Initial Setting /

Communication

Protect

Setting Change

Protect

Parameter Mask

Enable

PF Key Protect

Input Type *2

Scaling Upper Limit

(only when setting

analog input)

Scaling Lower Limit

(only when setting

analog input)

Decimal Point

(only when setting

analog input)

Temperature

Unit

SP Upper Limit

SP Lower Limit

in-t

5

in-h

100

in-l

0

dp

0

d-u

c

°C= c

°F= f

Initial setting level enables users to specify their preferred

operating conditions (input type, alarm type, etc.)

M

M

M

M

M

M

pru

m

pvst

sp

tspu

0

M

M

M

M

M

M

M

M

M

alt1

2

alh1

0.2

M

M

M

Transfer

Output Type

tr-t

off

Transfer Output

Upper Limit

tr-h

100.0

Transfer Output

Lower Limit

tr-l

0.0

Event Input

Assignment 1

Event Input

Assignment 2

Event Input

Assignments 3 to 6

Move to Advanced

Function Setting

Level

amov

0

Transfer

Output Signal

trst

4-20

M

M

M

M

ev-2

adv

ev-1

rr-1

M

M

ev-3

none

M

M

Close/Floating

Motor Calibration

clfl

flot

calb

off

mot

30

M

M

M

Travel Time

*2

Alarms 1 to 4 Type

Alarms 1 to 4

Hysteresis

Program Time Unit

Reset Operation

PV Start

Control Outputs 1

Signal

t-u

h-m

t-pr

time

rtsm

stop

p-on

cont

eset

rst

All PID AT Upper

Limit SP

sl-h

1300

M

sl-l

-200

Step Time/Rate of

Rise Programming

Time Unit of Ramp Rate

Startup Operation

Operation End

Operation

o1st

4-20

Control Period (Heating)

(Unit: Seconds)

*Voltage output

(for driving SSR): 2

cp

20

orev

or-r

In Direct operation (Cooling)

= or-d

In Reverse operation (Heating)

=

or-r

Direct/Reverse Operation

M

Hold Oand

Mkeys down

for at least 1

second

25

0

Hold Odown for at least 1 second

(No.1 display flashes, then the control stops.)

Hold Odown for at least 3 seconds

hold

off

ct1

0.0

pgsg

0.00

prg

0

a-m

r-r

rst

25

0

M

25

0

M

M

M

M

M

M

seg

0

M

M

stbm

0.00

prgt

0.00

M

M

rptm

0

M

M

s.err is displayed when

connected sensor is

different from input type.

Process Value/Set Point (1)

Process Value/Set Point (2)

s.err is displayed when

connected sensor is

different from input type.

Auto/Manual Switch

PID control only.

Program Number

Elapsed Program

Time Monitor

Program Execution

Repetition Monitor

Remaining Standby

Time Monitor

Segment Number

Hold

Program No. Monitor/

Segment No. Monitor

Heater Current 1 to 2

Value Monitor

(Unit: A)

Run/Reset

(of the program)

Operation level should normally

v-m

0.0

Valve Opening

Monitor

be used during operations.

Conformance to EN/IEC Standards

This is a class A product. In residential areas it may cause radio

interference, in which case the user may be required to take

adequate measures to reduce interference.

Conformance to Safety Standard

Reinforced insulation is provided between input power

supply, relay outputs, and between other terminals.

Do not allow temporary overvoltages on the primary circuit to exceed

the following values.

Check the power supply voltage to the Digital Controller.

Short-term overvoltage: 1,200 V + Power supply voltage

Long-term overvoltage: 250 V + Power supply voltage

Always externally connect the recommended fuse that is specified

in the Instruction Manual before you use the Digital Controller.

Analog Input

•

If you input an analog voltage or current, set the Input Type

parameter to the correct input type.

• Do not use the Digital Controller to measure a circuit with

Measurement Category II, III, or IV.

•

Do not use the Digital Controller to measure an energized circuit to

which a voltage that exceeds 30 Vrms or 60 VDC is applied.

The protection provided by the Digital Controller may be impaired if the

Digital Controller is used in a manner that is not specified by the

manufacturer.

23

24

11

12

35

36

19

20

21

22

9

10

31

32

33

34

2

25

7

8

175

6

29

30

3

4

26

27

28

113

14

15

16

18