©All Rights Reserved

2.Overvoltage category III.

3.This equipment is for protection class 1.

4.Climatic class: 3K3

: According to EN50178(=VDE0160).

Overvoltage category II.

: According to UL60950-1 and EN60950-1.

Surrounding Air Temperature

according to

UL508:40 °C

terminals ( ).

Safety standards

EN

Fig. 1

S8JX-P (300/600W)

OMRON Corporation

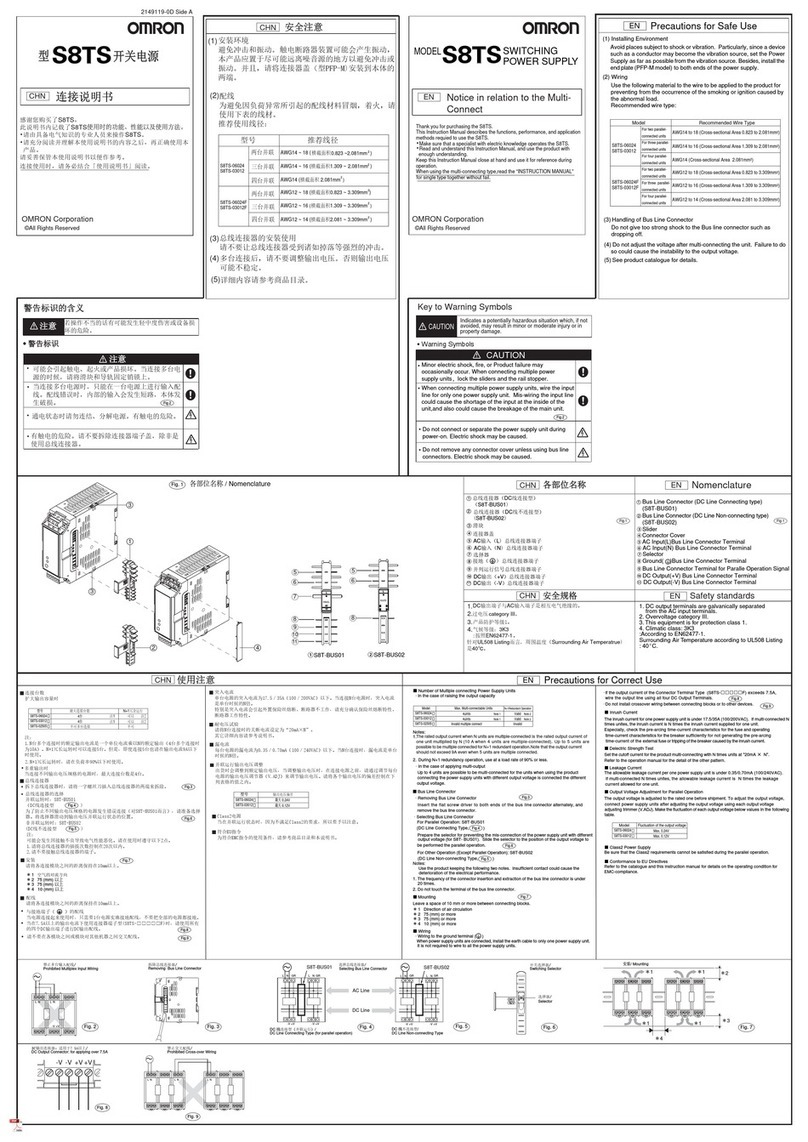

䜘ս〠Nomenclature Nomenclature

EN

ᆹޘ㿴Ṭ

䜘ս〠

CHN

Fig.1

Fig.1

Fig.1

Fig.1

INSTRUCTION MANUAL (1/2)

EN

2194719-3E (Side-A)

©All Rights Reserved

ᝏ䉒ᛘ䍝ҠҶS8JXӗ૱DŽ

↔䈤᰾Җ䇠䖭ҶS8JX֯⭘ᰦⲴ࣏㜭ǃᙗ㜭ԕ৺֯⭘ᯩ⌅DŽ

Ь䈧⭡ާ༷⭥≄⸕䇶ⲴуъӪઈᶕS8JXDŽ

Ь䈧ݵ࠶䰵䈫ᒦ⨶䀓ᵜ֯⭘䈤᰾ҖⲴᇩѻˈ↓⺞֯⭘ᵜ

ӗ૱DŽ

䈧࿕ழ؍㇑ᵜ֯⭘䈤᰾Җԕׯ৲㘳DŽ

䈧࣑ᗵ䰵䈫S8JX-P֯⭘䈤᰾Җ(2/2)ԕ৺ᵜ䈤᰾ҖDŽ

OMRON Corporation

ᔰޣ⭥Ⓚ

֯⭘䈤᰾Җ(1/2)

CHN

ර

Key to Warning Symbols

:DUQLQJ6\PEROV

䆖ḷ䇶Ⲵѹ

䆖ḷ䇶

2. 䗷⭥ category IIIDŽ

3. 䘉њ䇮༷Ѫ䱢ᣔㅹ㓗1DŽ

᤹➗EN50178(=VDE0160) DŽ

䗷⭥category IIDŽ

ṩᦞUL60950-1 ઼EN60950-1DŽ

CAUTION

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury or in

CAUTION

property damage.

CAUTION

Minor electric shock, fire, or Product failure may occasionally

occur. Do not disassemble, modify, or repair the Product or

touch the interior of the Product.

Minor burns may occasionally occur. Do not touch the Product

while power is being supplied or immediately after power is

turned OFF.

Minor fires may occasionally occur. Tighten terminal screws to

a WRUTXHRILQOE01P01PVRWKDWWKH\

do not become loose.

Minor electric shock, fire, or Product failure may occasionally

occur. Do not allow any pieces of metal or conductors or any

clippings or cuttings resulting from installation work to enter the

Product.

Working voltage can be 370V max. inside. This voltage can be

also available 30s after the switch off.

(1) Installing/Storage Environment

1.

Store the product with ambient temperature –25 to +75°C, and relative

humidity 25 to 90%.

2. The internal parts may occasionally deteriorate and be broken due to

adverse heat radiation depending on the mounting status.

Do not use at a temperature that exceeds the operating temperature range

for the mounting type.

3. The internal parts may occasionally be deteriorated or broken. Do not use

the

product in the condition over the operation ambient temperature range.

4.

Use the product where the relative humidity is 25 to 85%.

5. Avoid places where the product is subjected to direct sunlight.

6. Avoid places where the product is subjected to penetration of liquid, foreign

substance, or corrosive gas.

7. Avoid places subject to shock or vibration.

A device such as a contact breaker may be a vibration source. Set the

Power Supply as far as possible from possible sources of shock or vibration.

8. If the Power Supply is used in an area with excessive electronic noise,be

sure to separate the Power Supply as far as possible from the noise

sources.

9. The internal parts may occasionally deteriorate and be broken due to

adverse heat radiation.Do not loosen the screws on the Power Supply.

(2) Arrangement/Wiring

1. Connect the ground completely. A protective earthing terminal stipulated in

safety standards is used. Electric shock or malfunction may occur if the

ground is not connected completely.

2.

The light ignition may possibly be caused. Ensure that input and output

terminals are wired correctly.

3. Use the following wiring meterial to prevent smoking or ignition of wiring

material caused by abnormal loads.

Over heating or fire can result from inadequately sized wiring materials when

problems occur at the load. As a general rule, always select wire sizes

suitable for at least 1.6 times the rated current. Refer to the wiring

manufacturer’s recommended allowable current and voltage drop

specifications for information when selecting wiring materials.

Fig.2

4. Do not apply more than 75 N force to the terminal block when tightening it.

5. Be sure to remove the sheet covering the product for machining before

power-on.

Output Voltage Adjustment

1. The output voltage adjuster (V.ADJ) may possibly be damaged. Do not add

unnecessary power.

2.

Do not exceed the rated output capacity and current after adjusting the

output voltage.

Precautions for Safe Use

EN

ᆹޘ⌘

CHN

(1) ᆹ㻵ᆈۘ⧟ຳ

1.䈧൘⧟ຳᓖѪ–25+75 ˈሩ⒯ᓖѪ2590%ⲴᶑԦлۘ

㯿ᵜӗ૱DŽ

⭡Ҿᆹ㻵⣦ᘱнࠪ⧠Ⲵᮓ✝н㢟Պሬ㠤䜘ݳಘԦᙗ㜭ᚦᡆ

ᦏൿDŽ䈧н㾱൘䎵ࠪ䈕ᆹ㻵㊫රⲴ䘀㹼ᓖ㤳തⲴᓖл֯⭘ᵜ

ӗ૱DŽ

㜭Պᕅ䎧䜘ݳԦᦏǃᚦDŽ䈧н㾱൘䎵䗷֯⭘ᓖ㤳തⲴ

ᛵߥл֯⭘ᵜӗ૱DŽ

䈧൘ሩ⒯ᓖ2585%Ⲵ൪ᡰ֯⭘ᵜӗ૱DŽ

䈧н㾱൘ᰕݹⴤሴⲴ⧟ຳл֯⭘ᵜӗ૱DŽ

䈧н㾱൘⏢փˈᔲ⢙ԕ৺㞀㲰ᙗ≄փ㜭䘋ޕӗ૱䜘Ⲵ൪ᡰл

֯⭘ᵜӗ૱DŽ

䚯ݽߢ઼ࠫᥟࣘDŽ

䀖⭥ᯝ䐟ಘ㻵㖞㜭Պӗ⭏ᥟࣘˈᵜӗ૱ᓄ㖞Ҿቭ㜭䘌ಚ丣

ⓀⲴൠᯩԕ䚯ݽߢࠫᡆᥟࣘDŽ

ྲᵜӗ૱൘ާᴹ䖳ཊ⭥ᆀಚ丣Ⲵ⧟ຳлᐕᰦˈ䈧ቭ㜭ᢺᵜ

ӗ૱᭮㖞൘䘌ಚ丣ⓀⲴൠᯩDŽ

ྲᮓ✝н࡙ˈᵜӗ૱䜘ݳಘԦᙗ㜭㜭ᚦᡆᦏൿˈᡰԕ䈧

н㾱㠚ᤗᶮ⭥ⓀᵜփкⲴ㷪эDŽ

3.

4.

6.

7.

8.

9.

(2) 䇮㖞䝽㓯

ǂ㜭⭏䖫ᗞⲴ䎧⚛DŽ䈧⌘н㾱ሶ䗃ޕ䗃ࠪㄟᆀ䈟䝽㓯DŽ

ǂѪ䱢→ഐ䍏䖭ᔲᑨᡰᕅ䎧Ⲵ䝽㓯ᶀᯉⲴ߂✏ǃ䎧⚛ˈ䈧䘹ᤙ仍ᇊ

⭥⍱٬1.6ؽԕкⲴ㓯ᖴDŽޣҾ㓯ᶀⲴ䘹ᤙ䈧৲㘳⭥㓯লᇦⲴ᧘㦀

ݱ䇨⭥⍱઼⭥䱽ㅹ䍴ᯉDŽ

2.

3.

(3) 䗃ࠪ⭥䈳ᮤ

1.

2.

5.

䗃ࠪ⭥䈳㢲䫞(V.ADJ)㜭Պ㻛ᦏൿDŽᡰԕ䈧ᯭ࣐нᗵ㾱Ⲵ

ཆ࣋DŽ

䈧⺞؍൘䗃ࠪ⭥䈳ᮤˈн㾱䎵䗷仍ᇊ䗃࣏ࠪ⦷઼仍ᇊ䗃ࠪ⭥

⍱DŽ

Mounting

Standard mounting

Side mounting

Standard mounting (DIN rail)

S8JX-P300䕕䕕CD/ S8JX-P600䕕䕕CD

Install the Power Supply so that heat is effectively dissipated to

improve and maintain

the reliability of the Power Supply over a long period of time.

ᆹ㻵

ḷ߶ᆹ㻵

ח䶒ᆹ㻵

ḷ߶ᆹ㻵˄DINሬ䖘˅

S8JX-P300䕕䕕CD/ S8JX-P600䕕䕕CD

ᆹ㻵⭥ⓀᰦѪҶ㜭䮯ᵏ儈᭸ൠ֯⭘⭥Ⓚˈ䈧⌘⨶ᴹ᭸ൠᮓ✝DŽ

䟷⭘ᕪࡦ仾ߧⲴᮓ✝ᯩᔿDŽѪҶ㜭ᗇࡠ䏣ཏⲴ仾ߧ᭸ˈ䈧н㾱տ䙊仾

˄仾ᡷⲴ㻵䝽䶒઼৽䶒˅DŽ

ᖃᆹ㻵ᵪ༣кⲴ㷪эᰦˈ㷪э൘⭥Ⓚחケࠪнݱ䇨䎵䗷6mmDŽ

ᆹ㻵㷪эⲴᢝ⸙˄᧘㦀٬˅˖1PDŽ

ᕪ⛸᧘㦀䠁ᶯѪᆹ㻵䶒ᶯDŽ

㛼䶒ᆹ㻵ԕ֯⭘ᨀⲴᆹ㻵᭟DŽ

Fig.2

䗃ޕ⭥䘹ᤙ

仍ᇊ৲ᮠ˖

100ࡠ240 VACݱ䇨㤳ത˖85ࡠ264 VACˈ80ࡠ370 VDC

⌘˖

EUᤷԔ઼⿽ᆹޘḷ߶ULǃENㅹⲴ䘲⭘㤳തѪ100ࡠ240 VAC

85ࡠ264 VACDŽ

ӵሩҾUL508㘼䀰ˈ仍ᇊ৲ᮠѪ100-240 VACDŽ

㺠߿ᴢ㓯

㺠߿ᴢ㓯䈧৲㘳S8JXӗ૱ⴞᖅDŽ

Overload Protection

The load and the power supply are automatically protected from overcurrent damage by this

function.

Overload protection is activated if the output current rises above 105% of the rated current.

When the output current returns within the rated range, overload protection is automatically

cleared.

Notes:

1.

If operation is continued when the Power Supply has been short-circuited or in an overcurrent

status, internal parts in the Power Supply may occasionally deteriorate or be damaged.

2.The internal parts may possibly be deteriorated or damaged. Do not use the product for

applications where the load causes frequent inrush current and overload.

Overvoltage Protection

This power supply automatically protects itself and the load from overvoltage.

Overvoltage protection is activated if the output voltage rises above approx.

120% of the rated output voltage. The alarm indicator lights simultaneously.

To reset the power supply, leave the power supply off for more than 3 minutes and then turn it on

again.

Note:

Be sure to clear the cause of the overvoltage, before turning on the power supply.

If There Is No Output Voltage

The overload, overvoltage, or overheat protection functions may be operating. Alternatively,

the built-in fan may be stopped or the remote control function may be OFF. Check the following

five possible causes and contact your OMRON representative if there is still no output voltage.

&KHFNWKH2YHUORDG3URWHFWLRQ6WDWXV

Check whether the load is in overload status or is shorted.

Remove wires to load when checking.

$WWHPSWWR&OHDUWKH2YHUYROWDJH3URWHFWLRQ)XQFWLRQ

Turn input power OFF and leave it OFF for at least 3 minutes.

Then turn it ON again to see if this clears the condition. Check if the +S pin or –S pin is opened.

Check if the output voltage is adjusted to more than +20% of the ratedvalue with “V.ADJ” .

&KHFNWKH2YHUKHDW3URWHFWHG6WDWXV

Turn OFF the input power and leave it OFF until the product cools sufficiently. Turn it ON again

to see if this clears the condition.

&KHFNLIWKH%XLOWLQ)DQ0RWRU+DV6WRSSHG

Check if the built-in fan motor has stopped. The fan is a consumable product.

&KHFNWKH5HPRWH&RQWURO)XQFWLRQ

Check if the +RC and –RC pins are open. Make the correct connections as specified.

Precautions for Correct Use

EN

CHN ֯⭘⌘

4.

5.

Minor injury due to electric shock may occasionally occur. Do not

touch the terminals while power is being supplied. Always close

the terminal cover after wiring.

䪸ሩUL508㘼䀰ˈઘതᓖ(

Surrounding Air Temperature

)ᱟ40 DŽ

㜭Պᕅ䎧䀖⭥ǃ䎧⚛ᡆӗ૱ᦏൿDŽѕ⾱࠶ǃ᭩䙐ǃ

؞⨶ᵜӗ૱ᡆ䀖᪨ӗ૱䜘DŽ

㜭Պᕅ䎧䖫ᓖⲴ✛ՔDŽ䙊⭥ѝԕ৺⭥Ⓚࡊ࠷ᯝ䈧н

㾱傜к᧕䀖⭥ⓀᵜփDŽ

㜭Պᕅ䎧⟳✗DŽ䈧൘㿴ᇊᢝ⸙01P

01P)л㍗പㄟᆀ㷪эDŽ

㜭Պᕅ䎧ഐ䀖⭥ᡰሬ㠤Ⲵ䖫ՔDŽ䙊⭥ѝѕ⾱䀖᪨ㄟᆀˈ

䝽㓯䴰ޣ䰝ㄟᆀⴆDŽ

䙊⭥ᰦˈᵜփ䜘⭥ᴰབྷѪ370VDŽ࠷ᯝ⭥Ⓚ30。

Պ↻⮉↔⭥DŽ

㜭ᕅ䎧䖫ᓖ䀖⭥ˈ⟳✗ˈᵪಘ᭵䳌ㅹড䲙DŽ䈧н㾱֯

䠁ˈሬ㓯ᡆᆹ㻵࣐ᐕᰦӗ⭏Ⲵ㊹ቈ䘋ޕᵜӗ૱DŽ

㤕нᖃⲴ䈍ᴹ㜭⭏䖫ѝᓖՔᇣᡆ䇮༷ᦏ

ൿⲴড䲙DŽ

1.

2.

(3)

g

4. ≄ىㅹ㓗˖ 3K3

CHN

(Cross section 0.517 to 3.309mm )

The current rating for the output terminal is 60A per terminal. Make sure to use two terminals

together if a current exceeding the terminal rating is used.

8VHPLQ

60°C or 60/75°C wire.

8VHFRSSHUFRQGXFWRUVRQOy.(The stripping length is 7 to 8 mm for input terminals.)

Model Terminal

Input (M4)

Output (M5)

2

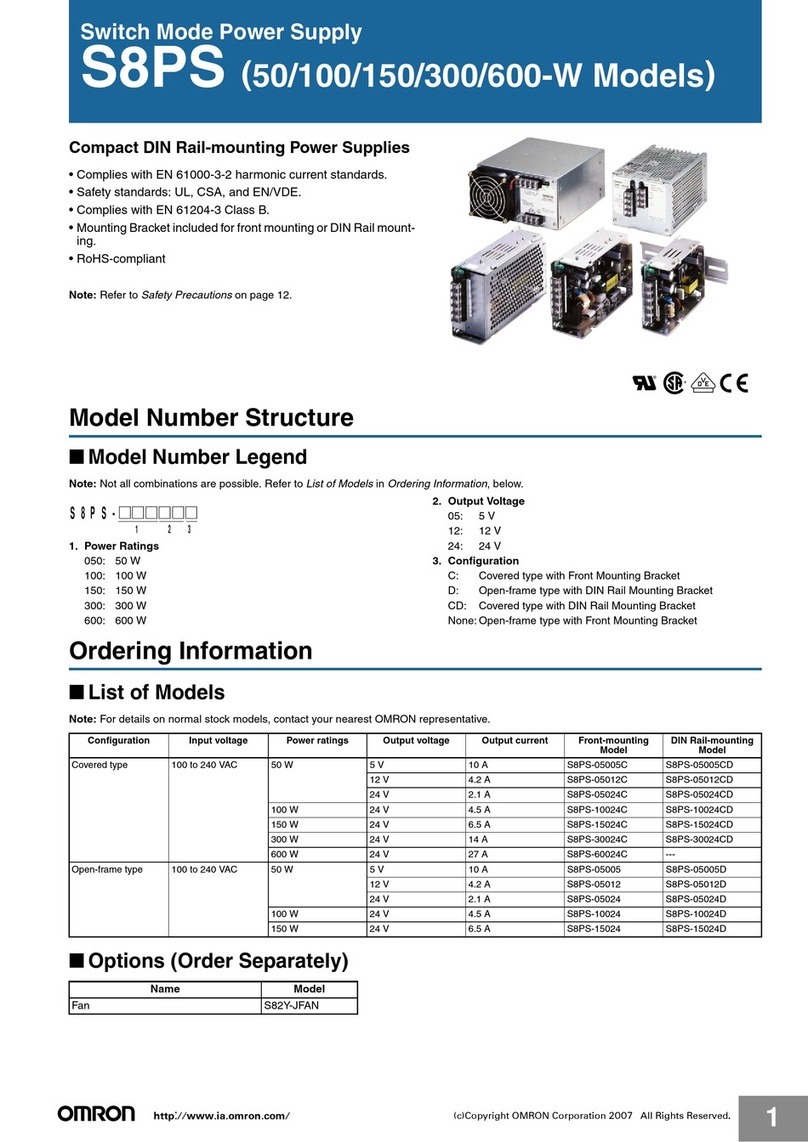

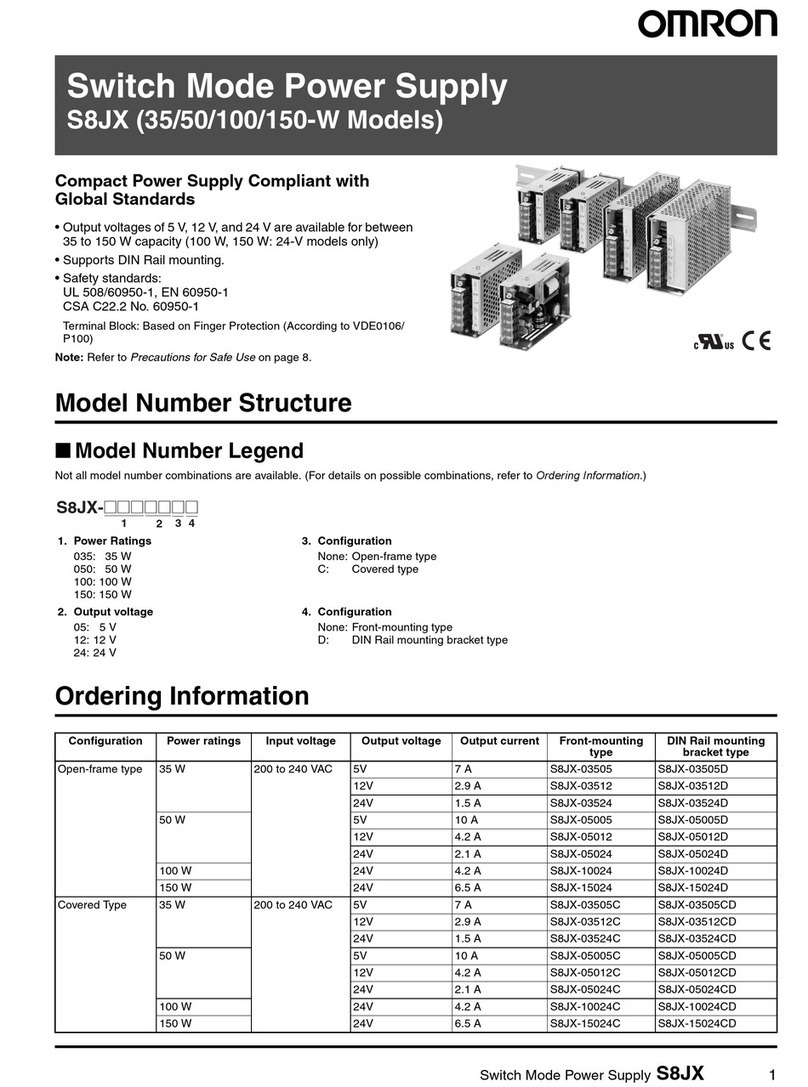

Thank you for purchasing the S8JX.

This Instruction Manual describesthe functions, performance,and

applicationmethods required to use the S8JX.

Makesure thata specialist with electric knowledgeoperates theS8JX.

Readand understand this Instruction Manual,and use the product with

enough understanding.

KeepthisInstruction Manual closeathand anduseit for referenceduring

operation.

Read the S8JX-P Instruction Manual (2/2) together with this manual

without fail.

Recommended Wire Type Torque

10 in.lb.(1.1m)

20 in.lb.(2.1m)

A forced-air cooling method with a fan is used.

Do not cover the air holes ( provided at fan mounted

side and the opposite side ) to have enough air-cooling.

The screws must not protrude more than 6mm inside the Power Supply when screw holes

provided on the chassis are used. Mounting screw tightening torque screw holes

(recommended value):1.27 1m

0HWDOSODWHLVVWURQJO\UHFRPPHQGHGDVWKHPRXQWLQJSDQHO

5HDUPRXQWLQJLVSRVVLEOHXVLQJSURYLGHGPRXQWLQJEUDFNHW

Derating Curve

For Derating Curve, refer to the S8JX Catalog.

Selecting input Voltage

Rating:

100 to 240 VAC (allowable range: 85 to 264 VAC, 80 to 370 VDC)

Note:

The applicable range of EU directives and various safety standards (UL, EN, others) is 100 to

240 VAC (85 to 264 VAC).

For UL508 only, the rating is 100-240 VAC.

Dielectric Strength Test

Rated dielectric strength:

3000VAC between <input terminals together > and <output terminals together> for 1

minute. When testing, set the cutoff current for the withstand voltage test device to 20mA.

Notes:

1.Sudden switching of 3000VAC may possibly cause a voltage surge, damaging the power

supply. Increase/decrease test voltage gradually.

2.When performing the test, be sure to short-circuit all the output terminals to protect them from

damage.

Overheat Protection

If the temperature inside the power supply rises abnormally due to the ambient temperature rising

or the fan stopping, the overheat protection circuit activates and stops output to protect the power

supply unit.

To reset, turn off the input power, allow the unit to cool sufficiently, and then turn on the input

power again.

Conformance to EU Directives

Refer to the catalogue and this instruction manual for details on the operating condition for

EMC-compliance.

䈧ᆼޘ᧕ൠDŽ⺞؍᧕ൠㄟᆀ༴Ҿᆹޘ֯⭘⣦ᘱDŽ

ᖃ᧕ൠнᆼޘᰦˈ㜭Պᕅ䎧䀖⭥઼䈟ࣘDŽ

AWG12 to 20

⇿њ䗃ࠪㄟᆀⲴ仍ᇊ⭥⍱Ѫ60ADŽྲ⭥⍱䎵䗷ㄟᆀⲴ仍ᇊ٬ᰦˈ䈧⺞؍ᰦ

֯⭘єњㄟᆀDŽ

䈧֯⭘60 ԕкᡆ60/75 Ⲵ㓯ᶀDŽ

䈧֯⭘ሬփ䜘࠶Ѫ䬌㓯Ⲵ㓯ᶀDŽо䗃ޕח䘎᧕Ⲵ㼨㓯䮯ᓖѪPPࡠPPDŽ

ර ᧘㦀֯⭘㓯ᖴ ᢝ⸙

(⁚ᡚ䶒〟 0.517 to 3.309mm )

2

10 in.lb.(1.131m)

㍗പㄟᆀᰦˈ䈧н㾱⭘75NԕкⲴ࣋৫᤹ㄟᆀDŽ

Ѫ֯ᮓ✝䙊ˈ䙊⭥ࡽ䈧л࣐ᐕᰦ㾶ⴆ൘ӗ૱кⲴ㮴㟌DŽ

g

g

g

g

䗷䖭؍ᣔ

䈕࣏㜭ԕ㠚ࣘ؍ᣔ䍏䖭઼⭥Ⓚݽ䗷⭥⍱ⲴᦏᇣDŽྲ䍏䖭䎵䗷仍ᇊ٬Ⲵ

105%ˈ䗷䖭؍ᣔᔰᐕDŽᖃ䗷䖭⣦ᘱ䀓䲔ᰦˈ䗷䖭؍ᣔ㠚ࣘ⎸DŽ

ᖃ䗷䖭⣦ᘱᤱ㔝。ԕкᰦˈ⭥Ⓚ䗃ࠪ࠷ᯝˈᰦ؍ᣔഎ䐟ࣘᤷ⽪⚟ՊӞ䎧DŽ

⌘˖

1ྲ൘⭥Ⓚ⸝䐟ᡆ䗷⭥⍱⣦ᘱлᤱ㔝䘀㹼ˈ⭥Ⓚ䜘ݳಘԦᙗ㜭㜭ᚦᡆᦏ

ൿDŽ

2䈧н㾱൘䗷䖭ᡆ䗃ࠪח⎚⎼⭥⍱仁㑱⭏Ⲵᛵߥл֯⭘䈕ӗ૱DŽ⭥Ⓚ䜘ݳಘ

Ԧᙗ㜭㜭ᚦᡆᦏൿDŽ

䗷⭥؍ᣔ

䈕⭥Ⓚ㜭ཏ㠚ࣘ؍ᣔ㠚䓛৺䍏䖭ݽ䗷⭥ⲴᦏᇣDŽ

ྲ䗃ࠪ⭥䎵䗷仍ᇊ䗃ࠪ⭥㓖120%ԕкᰦˈ䗷⭥؍ᣔᔰᐕˈᣕ䆖ᤷ⽪

⚟ᰦӞ䎧DŽ

ྲ㾱䇙⭥Ⓚ༽սˈ䈧ݸሶ⭥Ⓚ䗃ޕ࠷ᯝᒦ᭮㖞3࠶䫏ԕк❦䟽ᯠᔰ⭥ⓀDŽ

⌘

൘䟽ᯠᔰѻࡽ䈧⺞؍ᕅ䎧䗷⭥Ⲵഐᐢ㻛ᧂ䲔DŽ

AC input terminal (L), (N)

(The fuse is located on the (L) side.)

For DC input, (L) side must be (+).

Note:

DC input is out of the scope of safety standard certificate.

Protective earthing terminal ( )

(A protective earthing terminal stipulated insafety standards is

used. Connect the ground completely.)

DC output terminal (–V), (+V)

Output indicator (DC ON: green)

Output voltage adjuster (V.ADJ)

Alarm indicator (ALM: red)

Signal input/output connector Instruction Manual (2/2)

1.DC output terminals ( ) are galvanically isolated from the AC input

Fig.2

㙀⭥ᇎ傼

仍ᇊ㙀⭥˖

3000VACҾ<ᡰᴹ䗃ޕㄟᆀ>઼<ᡰᴹ䗃ࠪㄟᆀ>ѻ䰤ᤱ㔝1࠶䫏DŽ

ᇎ傼ᰦˈ㙀⭥⍻䈅㻵㖞Ⲵ࠷ᯝ⭥⍱䇮㖞Ѫ20mADŽ

⌘˖

1ケ❦࣐䖭3000VAC儈㜭ӗ⭏⭥ߢࠫ㘼ᦏൿ⭥ⓀDŽ䈧㕃ធ໎࣐

߿ሿᇎ傼⭥DŽ

2ᇎ傼ᰦˈ⸝᧕ᡰᴹ䗃ࠪㄟᆀԕ䚯ݽㄟᆀᦏDŽ

Fig.3

Fig.4

Fig.2

Fig.3

Fig.4

㔍㕈⭥䱫ᇎ傼

ᇎ傼䟷⭘ⴤ⍱500VDC⅗㺘DŽ

⌘˖

ᇎ傼ᰦˈ⸝᧕ᡰᴹ䗃ࠪㄟᆀԕ䚯ݽㄟᆀᦏDŽ

EN60950-1઼EN50178ḷ߶ሩᇒᡧⲴ㾱≲˖

ᇒᡧᗵ享൘⭥ⓀS8JX-P600ƶƶƶƶࡽⲴ˄L˅ח࣐ањㅖḷ߶

˄IEC60127˅Ⲵ儈࠶ᯝ㜭࣋⟄ᯝಘˈഐѪ⭥Ⓚ䜘Ⲵ؍䲙энㅖ

IEC60127Ⲵḷ߶DŽ

Insulation Resistance Test

When testing the insulation resistance of the power supply, use a DC ohmmeter at 500VDC.

Note:

When performing the test, be sure to short-circuit all the output terminals to protect them from

damage.

EN 60950-1 and EN 50178 Requirement to the customer:

Customers must insert an approved (IEC 60127) high-breaking-capacity fuse in front of the

power supply S8JX-P600䕕䕕䕕䕕 on the (L) side, as the fuse in this power supply does not

comply with IEC 60127.

AC䗃ޕㄟᆀ(L)ˈ(N)

(؍䲙эսҾ(L)חDŽ)

DC䗃ޕᰦˈ(L)חᗵ享Ѫ(+)DŽ

⌘˖

DC䗃ޕн൘ᆹޘḷ߶䇔䇱㤳തѻDŽ

᧕ൠ؍ᣔㄟᆀ( ǂ)

(֯⭘ᆹޘ㿴Ṭᡰ㿴ᇊⲴ᧕ൠ؍ᣔㄟᆀˈ䈧⺞؍࿕ழ᧕ൠDŽ)

䗃ࠪ⭥䈳㢲䫞(V.ADJ)

䗃ࠪᤷ⽪⚟(DC ON˖㔯㢢)

ᣕ䆖ᤷ⽪⚟(ALM˖㓒㢢)

ؑ䗃ޕ䗃ࠪ䘎᧕ಘ֯⭘䈤᰾Җ(2/2)

DC䗃ࠪㄟᆀ(–V)ˈ(+V)

䗃ࠪ⭥䈳ᮤ

ࠪলᰦ˖䇮ᇊ䗃ࠪ⭥Ѫ仍ᇊ⭥DŽ

䈳ᮤ㤳ത˖֯⭘ӗ૱↓䶒Ⲵ"V.ADJ" 䘋㹼䈳ᮤˈ䈳ᮤ㤳തӾ仍ᇊ⭥Ⲵ

–10%ࡠ+15%48 V㊫රӗ૱кѪ±10%DŽ

亪ᰦ䪸䖜ᰦ໎བྷ䗃ࠪ⭥ˈ䘶ᰦ䪸䖜ᰦ߿ሿ䗃ࠪ⭥DŽ

⌘˖

1. 䈧⺞؍൘䗃ࠪ⭥䈳ᮤˈн㾱䎵䗷仍ᇊ䗃࣏ࠪ⦷઼仍ᇊ䗃ࠪ⭥⍱DŽ

2. 䙊䗷"V.ADJ" Ⲵ䈳㢲ˈ䗃ࠪ⭥㜭кࡠ⭥㤳തѻкDŽ

ᡰԕ䈳ᮤ䗃ࠪ⭥ᰦˈ䈧⺞䇔⭥ⓀⲴ䗃ࠪ⭥ᒦ䱢→䍏䖭䚝ࡠൿDŽ

Default Setting: Set at the rated voltage.

Adjustable Range: Adjustable from –10% to +15% (±10% on the 48 V type) of the rated voltage

using "V.ADJ " on the front of the unit.

Turning clockwise increases the output voltage, and turning counterclockwise decreases the

output voltage.

Notes:

1.Do not exceed the rated output capacity and current after adjusting the output voltage.

2.The output voltage may increase beyond the allowable voltage range when the operation is

performed for "V.ADJ" . When adjusting the output voltage, check the output voltage of the

power supply and be sure that the load is not destroyed.

Output Voltage Adjustment

AWG 6 to 20

(⁚ᡚ䶒〟 0.517 to 13.30mm )

2

20 in.lb.(2.251m)

ㄟᆀ

䗃ޕ

(M4)

䗃ࠪ

(M5) AWG12 to 20

(Cross section 0.517 to 13.30mm )

2

AWG6 to 20

MODEL

S8JX-P (300/600W)

SWITCHING POWER SUPPLY

S8JX-P300

S8JX-P600

S8JX-P300

S8JX-P600

䗷✝؍ᣔ

ྲ⭡Ҿ⧟ຳᓖ儈ᡆ仾ᡷڌ→㘼䙐ᡀ⭥Ⓚ䜘ᓖᔲᑨ儈ˈ䗷✝؍ᣔ⭥

䐟Պࣘᒦڌ→䗃ࠪˈԕ؍ᣔ⭥ⓀঅݳDŽ

ྲ㾱༽սˈ䈧ޣ䰝䗃ޕ⭥Ⓚˈ֯ӗ૱ݵ࠶ߧতˈ❦䟽ᯠᔰ䗃ޕ⭥ⓀDŽ

ྲ⋑ᴹ䗃ࠪ⭥

䗷䖭ǃ䗷⭥ᡆ䗷✝؍ᣔ࣏㜭㜭↓൘䘀㹼DŽᡆ㘵ˈ㖞仾ᡷڌ→ᡆ䚕᧗࣏㜭

ޣ䰝DŽྲ❦⋑ᴹ䗃ࠪ⭥ˈ䈧Ựḕᱟᆈ൘ԕл5⿽㜭Ⲵഐˈᒦ㚄㌫⅗

嗉ԓ㺘DŽ

Ựḕ䗷䖭؍ᣔ⣦ߥ˖

Ựḕ䍏䖭ᱟ༴Ҿ䗷䖭⣦ᘱᡆ⸝䐟⣦ᘱDŽ

Ựḕᰦ䈧〫䲔᧕൘䍏䖭кⲴ䘎㓯ˈⴻк䘠⣦ᘱᱟᐢ㻛⎸䲔DŽ

ѪҶ⎸䲔䗷⭥؍ᣔ࣏㜭˖

ޣ䰝䗃ޕ⭥Ⓚˈ᭮㖞3࠶䫏ԕкDŽ

❦ሶަᔰˈⴻк䘠⣦ᘱᱟᐢ㻛⎸䲔DŽỰḕ+Sᕅ㝊ᡆ–Sᕅ㝊ᱟᔰ䐟DŽ

Ựḕᱟ⭘"V.ADJ" ሶ䗃ࠪ⭥䈳ᮤѪ仍ᇊ٬Ⲵ+20%ԕкDŽ

Ựḕ䗷✝؍ᣔ⣦ߥ˖

ޣ䰝䗃ޕ⭥Ⓚˈᒦ؍ᤱޣ䰝⣦ᘱˈⴤ㠣ӗ૱ݵ࠶ߧতDŽ❦ሶަᔰˈⴻк

䘠⣦ᘱᱟᐢ㻛⎸䲔DŽ

Ựḕ㖞仾ᡷ⭥ᵪᱟڌ→˖

Ựḕ㖞仾ᡷ⭥ᵪᱟڌ→DŽ仾ᡷѪ⎸㙇ӗ૱DŽ

Ựḕ䚕᧗࣏㜭˖

Ựḕ+RC઼–RCᕅ㝊ᱟᔰ䐟DŽṩᦞᤷᇊ䘋㹼↓⺞Ⲵ䘎᧕DŽ

ㅖEUᤷԔ

䈧৲㘳୶૱ⴞᖅ઼ᵜ֯⭘䈤᰾Җᶕ㧧ᗇㅖEMCᤷԔⲴ֯⭘ᶑԦDŽ

g

g

g

g

)оAC䗃ޕㄟᆀᱟӂ⭥≄㔍㕈ⲴDŽ

1. DC䗃ࠪㄟᆀ(()

⅗嗉㠚ࣘ˄ѝഭ˅ᴹ䲀ޜ

ൠ൰˖ѝഭк⎧ᐲ⎖ьᯠ䬦ѝ䐟

ѝ䬦བྷᇔ

⭥䈍˖˄˅

CHN /

ࡦ䙐୶ CHN ᢰᵟ䈒

⅗嗉˄к⎧˅ᴹ䲀ޜ

ൠ൰˖ѝഭк⎧ᐲ⎖ьᯠ䠁ẕ࣐ࠪᐕ䠁䐟

⭥䈍˖˄˅

ᢰᵟ䈒✝㓯˖

㖁൰˖KWWSZZZIDRPURQFRPFQ

S8JX-P300 S8JX-P600

:W006:W003

2

3

57 3

7

6

4

5

12

1

64

Fig. 2 ḷ߶ᆹ㻵/Standard mounting Fig. 3 ח䶒ᆹ㻵

/ Side mounting Fig. 4 ḷ߶ᆹ㻵˄DINሬ䖘˅

/Standard mounting (DIN rail)

൘DINሬ䖘к䘋㹼ᆹ㻵ᰦˈ䈧֯⭘䫱ࡦDINሬ䖘

/When mounting on DIN rails, use iron DIN rails.

50

mm min

50

mm min

15

mm min

15

mm min

50

mm min

50

mm min

15

mm min

15

mm min

Suitability for Use

EN

Omron Companies shall not be responsible for conformity with any standards, codes or

regulations which apply to the combination of the Product in the Buyer’ s application or use of

the Product. At Buyer’ s request, Omron will provide applicable third party certification

documents identifying ratings and limitations of use which apply to the Product. This information

by itself is not sufficient for a complete determination of the suitability of the Product in

combination with the end product, machine, system, or other application or use. Buyer shall be

solely responsible for determining appropriateness of the particular Product with respect to

Buyer’ s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO

LIFE OR PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT

THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

CHN ֯⭘ᰦⲴ⌘һ亩

൞ᇘᡭⲺᓊ⭞ѣθ⅝嗏у䍕䍙ӝфԱᇘᡭㄥӝᡶ⎿Ⲻ㿺ṲȽ

㿺㤹ૂḽؓᤷж㠪ᙝȾ䈭ࣗᗻ㘹㲇ᵢӝሯӄᡶᓊ⭞Ⲻ㌱㔕Ƚᵰಞૂ

䇴༽䰪Ⲻ䘸⭞ᙝȾֵ⭞ᰬ䈭⌞ᝅᒬ䚫ᆾᵢӝⲺ⾷↘Ӂ亯Ⱦ

൞⋗ᴿ⺤䇚᮪Ѡ㌱㔕䇴䇗ᰬᡶ㘹㲇ࡦⲺ伄䲟θԛ⋗ᴿ⺤䇚൞䇴༽ૂ㌱

㔕ѣ䈛⅝嗏ӝⲺ仓ᇐֵ⭞ᶗԬૂ↙⺤ᆿ㻻ᶗԬⲺ߫сθ⾷↘ሼᵢ

ӝᓊ⭞ӄሯӰ䓡䍘ӝᆎ൞ћ䠃ধ䲟Ⲻ൰Ⱦ

䈜㿷ӝ㿺ṲҜѣؓ䇷ރ䍙Ӂ亯ᇯȾ