©All Rights Reserved

OMRON Corporation

3116647-5A (Side-B)

EN Contact address

OMRON ELECTRONICS LLC

Phone: 1-800-55-OMRON

Phone: 1-847-843-7900

Fax : 1-847-843-7787

OMRON CANADA INC.

Phone: 1-416-286-6465

Phone: 1-866-986-6766

Fax : 1-416-286-6648

UNITED KINGDOM

OMRON ELECTRONICS LTD.

Phone: 44-1908-258-258

Fax : 44-1908-258-158

1

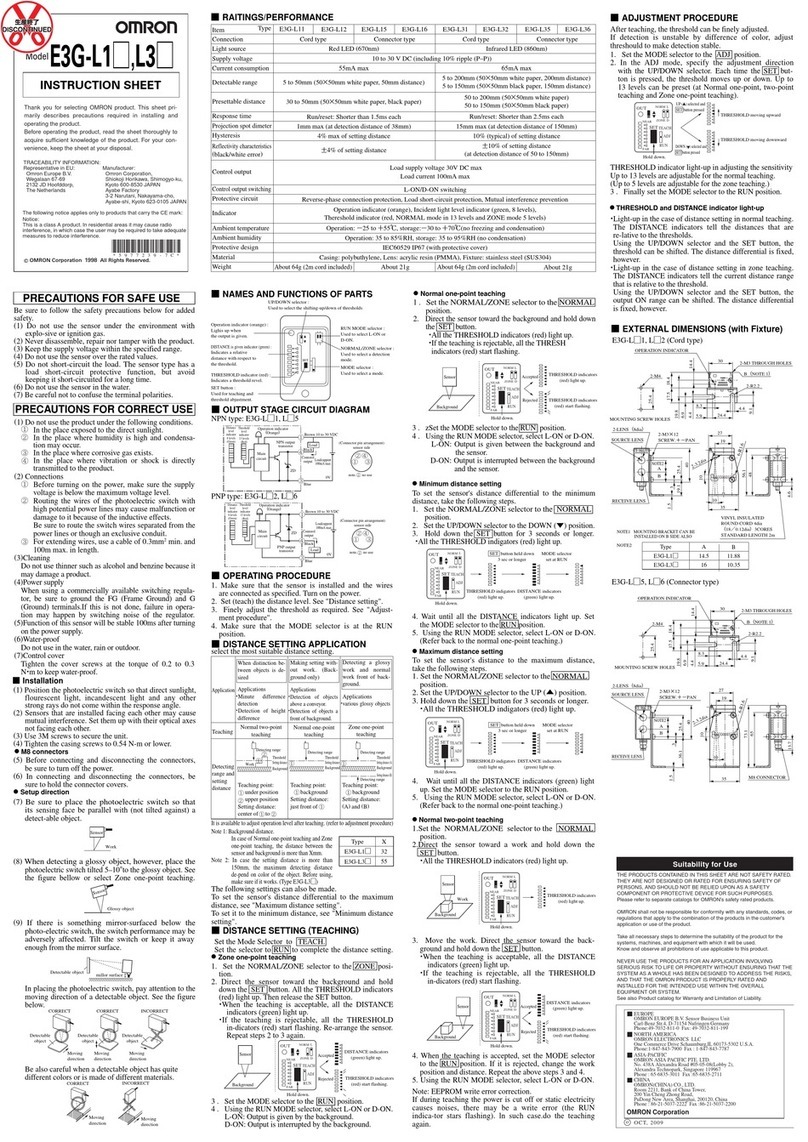

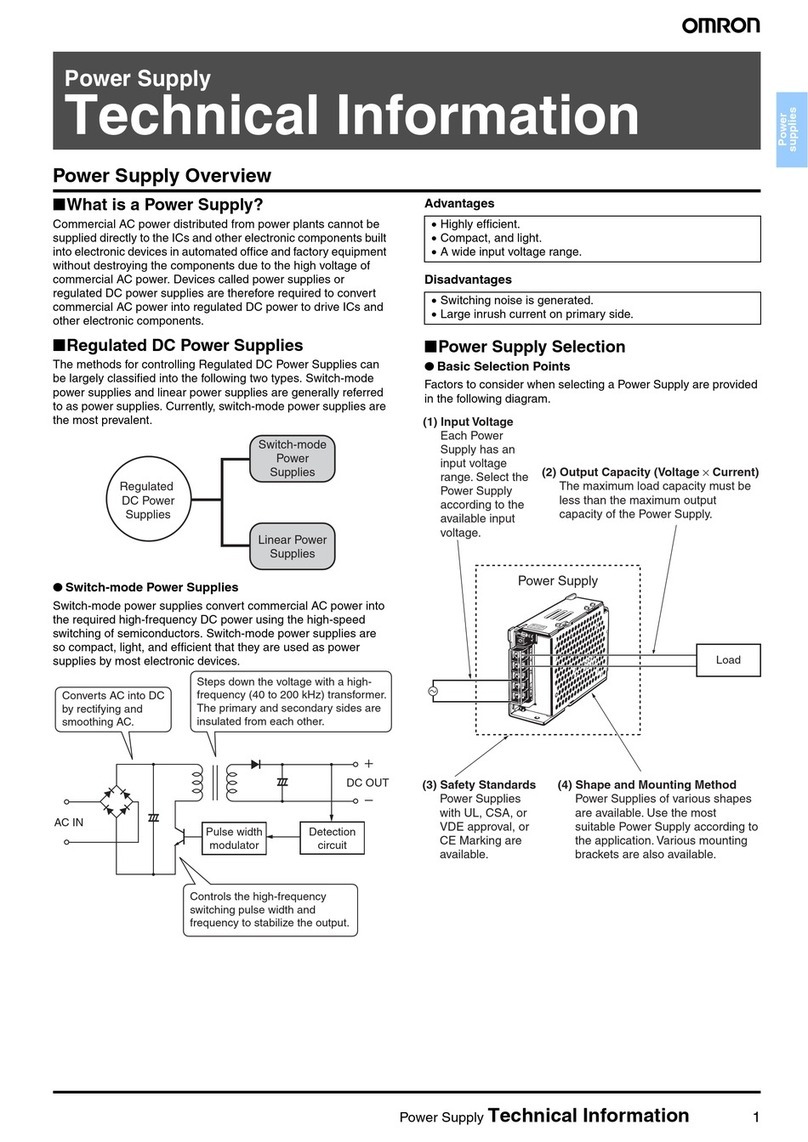

Fig. Nomenclature

Fig.1

Safety standards

EN

① Overvoltage category II.

: Complies with GB4943-2011.

② Use in pollution degree2 environment.

: Complies with GB4943-2011.

③ Conformance to GB4943.1-2011 standards for ambient temperature.

35℃(S8FS-G150□□□)

④ (S8FS-G150□□□)series power supply could be used in information technology

products.

: Complies with GB4943-2011.

≤2000m

⑤Only for safe use below 2000 meters altitude.

: Complies with GB4943-2011.

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku, kyoto, 600-8530 Japan

OMRON Europe B.V.

Wegalaan 67-69, 2132 JD Hoofddorp, The Netherlands

S8FS-G SWITCHING

POWER SUPPLY

MODEL

INSTRUCTION MANUAL

EN

Thank you for purchasing the S8FS-G.

This Instruction Manual describes the functions, performance, and

application methods required to use the S8FS-G.

• Make sure that a specialist with electric knowledge operates the S8FS-G.

• Read and understand this Instruction Manual, and use the product with

enough understanding.

Keep this Instruction Manual close at hand and use it for reference during operation.

⑧

⑦

④

⑤

⑨

⑥

②

③

①

This diagram show the S8FS-G150C

S8FS-G150

Nomenclature

EN

①and ②

Input terminals (L), (N)

(The fuse is located on the (L) side.)

③Protective earthing terminal (

)

(This is the protective earthing terminal

specified in the safety standards. Always

ground this terminal.)

④, ⑤, ⑥and ⑦

DC output terminals (–V), (+V)

⑧Output indicator (DC ON: green)

⑨Output voltage adjuster

EN Key to Warning Symbols

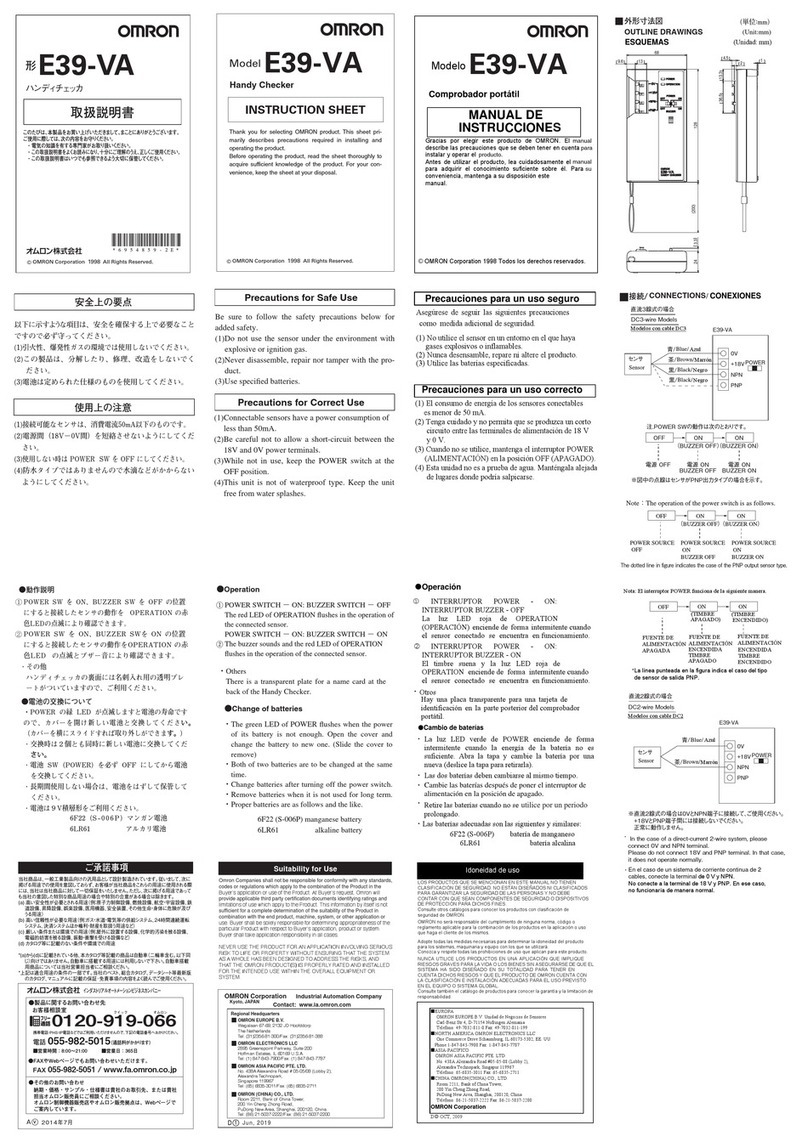

Fig.2

Precautions for Safe Use

EN

CAUTION

CAUTION

• Warning Symbols

Suitability for Use

EN

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which

apply to the combination of the Product in the Buyer’ s application or use of the Product. At Buyer’ s

request, Omron will provide applicable third party certification documents identifying ratings and limitations

of use which apply to the Product. This information by itself is not sufficient for a complete determination of

the suitability of the Product in combination with the end product, machine, system, or other application or

use. Buyer shall be solely responsible for determining appropriateness of the particular Product with

respect to Buyer’ s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FORAN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURINGTHAT THE SYSTEM AS A WHOLE HAS

BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY

RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or in property damage.

• Minor electric shock, fire, or Product failure may occasionally occur. Do not

disassemble, modify, or repair the Product or touch the interior of the Product.

• Minor electric shock, fire, or Product failure may occasionally occur. Do not

allow any pieces of metal or conductors or any clippings or cuttings resulting

from installation work to enter the Product.

(1) Installation and Storage Environment

1. Store the Product at a temperature of −25 to 75°C and a humidity of 90% or less.

2. Take adequate measures to ensure proper heat dissipation to increase the

long-term reliability of the Product.

The S8FS-G150 are cooled by natural convection.

Mount them so that air convection will occur around them.

3. The internal parts may occasionally deteriorate or be damaged. Do not use the

Product beyond the derating curve range.

4. Refer to the Product catalog for the derating curve for each mounting direction.

5. Use the Product at a humidity of 90% or less.

6. Avoid places where the Product is subjected to direct sunlight.

7. Avoid places where the Product is subjected to penetration of liquid, foreign

substance, or corrosive gas.

8. Avoid places subject to shock or vibration.

A device such as a contact breaker may be avibration source. Set the Power

Supply as far as possible from possible sources of shock or vibration.

9. If the Power Supply is used in an area with excessive electronic noise, be sure to

separate the Power Supply as far as possible from the noise sources.

10. The internal parts may occasionally deteriorate and be broken due to adverse heat

radiation. Do not loosen the screws on the Power Supply.

(2) Installation and Wiring

1.

Connect the ground completely. A protective earthing terminal stipulated in safety standards

is used. Electric shock or malfunction may occur if the ground is not connected completely.

2. The light ignition may possibly be caused. Ensure that input and output terminals

are wired correctly.

3. Use the following wiring material to prevent smoking or ignition of wiring material

caused by abnormal loads.

Notes:

1. The current rating per terminal of the output terminals is shown below. If the current exceeds the rating

on a terminal, always use two terminals simultaneously.

• S8FS-G150: 20 A

2. After completing the wiring, create the following clearance and creepage distance between the terminal

wires and metal case.

Between any two of wires connected to the L, N and FG ( ) terminals and between wires connected

to L, N terminals and the metal case: 6.4mm min.

Between any two of wires connected to the +V, -V and FG ( ) terminals and between wires

connected to +V, -V terminals and the metal case: 3.2mm min.

4. Do not apply more than 150 N force to the terminal block when tightening it to avoid

the terminal block damaged.

5. Be sure to remove the sheet covering the product for machining before power-on.

(3) Output Voltage Adjustment

1. The output voltage adjuster (V.ADJ) may possibly be damaged. Do not add

unnecessary power.

2.

Do not exceed the rated output capacity and current after adjusting the output voltage.

(4) Refer tothe other Instructions Manual (3114994-5) for details on the optional models

(S8FS-GE, S8FS-G-R, and S8FS-G-W).

(5) Refer to the product datasheet for details.

• Minor injury due to electric shock may occasionally occur. Do not touch the

terminals while power is being supplied. Always close the terminal cover after

wiring. Working voltage can be 370 V max. inside. This voltage can be also

available 30s after the switch off.

• Minor fires may occasionally occur. Tighten terminal screws to the specified

torque (M3.5 screws: 6.55 to 10.00 lb-in (0.74 to 1.13 N•m), M4 screws: 9.56

to 11.68 lb-in (1.08 to 1.32 N•m)).

• Minor burns may occasionally occur. Do not touch the Product while power is

being supplied or immediately after power is turned OFF.

Terminal Model Torque

Recommended

wire type

Input 6.55 to 10.00 lb-in

(0.74 to 1.13 N•m)

Output

Protective earthing

terminal

AWG12 to 16

AWG12 to 14

S8FS-G150

S8FS-G150

AWG12 to 16

6.55 to 10.00 lb-in

(0.74 to 1.13 N•m)

S8FS-G150

Precautions for Correct Use

EN

Fig.3

Fig.2

■Mounting

Standard mounting

Standard Mounting on DIN Rail

S8FS-GCD

• When the screw holes provided on the chassis are used, the screws must not

protrude more than 3 mm

inside the Power Supply. If you must use screws that are longer than given above,

refer to the product datasheet.

Tighten the mounting screws to the following torque:

M3 screws: 0.48 to 0.59 N·m

M4 screws: 1.08 to 1.32 N·m

• Metal plate is strongly recommended as the mounting panel.

■Input Voltage Tolerance

Rating: 100 to 240 VAC

• Mains supply tolerance for AC input: -10 to +10% (90 to 264 VAC)

■Parallel Operation

This Power Supply is not designed for parallel operation. If you attempt parallel

operation, overheating may damage internal parts.

Parallel operation is possible with the optional models (S8FS-G60024-W).

■Output Voltage Adjustment

Default Setting: Set at the rated voltage

Adjustable Range: Adjustable with "V.ADJ "

⑨

on the front surface of the product

from –10% to +15% of the rated output voltage.

Turning clockwise increases the output voltage, and turning counterclockwise

decreases the output voltage.

Note:

The output voltage may increase beyond the voltage adjustment range +15% or

more when the V.ADJ adjuster ⑨ is used.

When adjusting the output voltage, check the output voltage of the Power Supply

and be sure that the load is not destroyed.

■Dielectric Strength Test

Rated dielectric strength:

3,000 VAC between < input terminals ①②together > and < output terminals ④⑤⑥

⑦

together > for 1 minute.

When testing, set the cutoff current for the withstand voltage

test device to 20 mA.

Notes:

1. If a tester switch is used to apply or cut off 3,000 V suddenly, the resulting

impulse voltage may occasionally damage the Product.

2. When performing the test, be sure to short-circuit all the output terminals to

protect them from damage.

■Insulation Resistance Test

When testing the insulation resistance of the Power Supply, use a DC ohmmeter

at 500 VDC.

Note:

When performing the test, be sure to short-circuit all the output terminals to protect

them from damage.

■Overload Protection

The load and the Product are automatically protected from overcurrent damage

by the overload

protection function. When the current returns to within the rated range, the Product

will automatically return to normal operation.

Notes:

1. Internal parts may possibly deteriorate or be damaged if a short-circuited,

overload, or boost load state continues during operation.

2. Internal parts may possibly deteriorate or be damaged if the Product is used for

applications with frequent inrush current or overloading at the load end. Do not

use the Product for such applications.

■Overvoltage Protection

This Product automatically protects itself and the load from overvoltage.

Overvoltage protection is activated if the output voltage rises above approx.

120% of the rated output voltage. To reset the Product, leave the Product off for

more than 3 minutes and then turn it on again.

Note:

Be sure to clear the cause of the overvoltage, before turning on the Product.

■Conformance to EU Directives

Refer to the catalogue and this instruction manual for details on the operating

condition for EMC-compliance.

If you use the S8FS-G150 at 80% or more of the rated load, the harmonics

standard will not be met. Do not connect the Product to a public power source when

you operate it at 80% or more of the rated load.

S8FS-G150

20 mm min. 20 mm min.

20 mm min. 20 mm min.

∗ ∗

Fig. 2 Standard mounting Fig. 3 Standard mounting (DIN rail)

20 mm min.