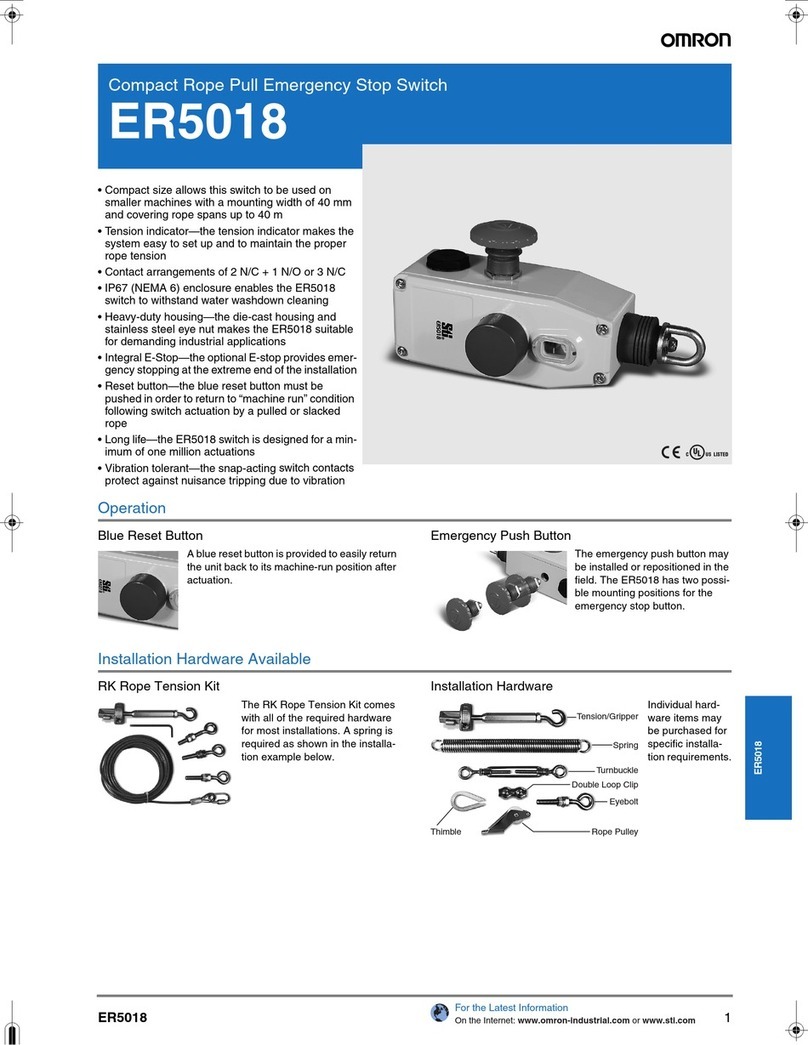

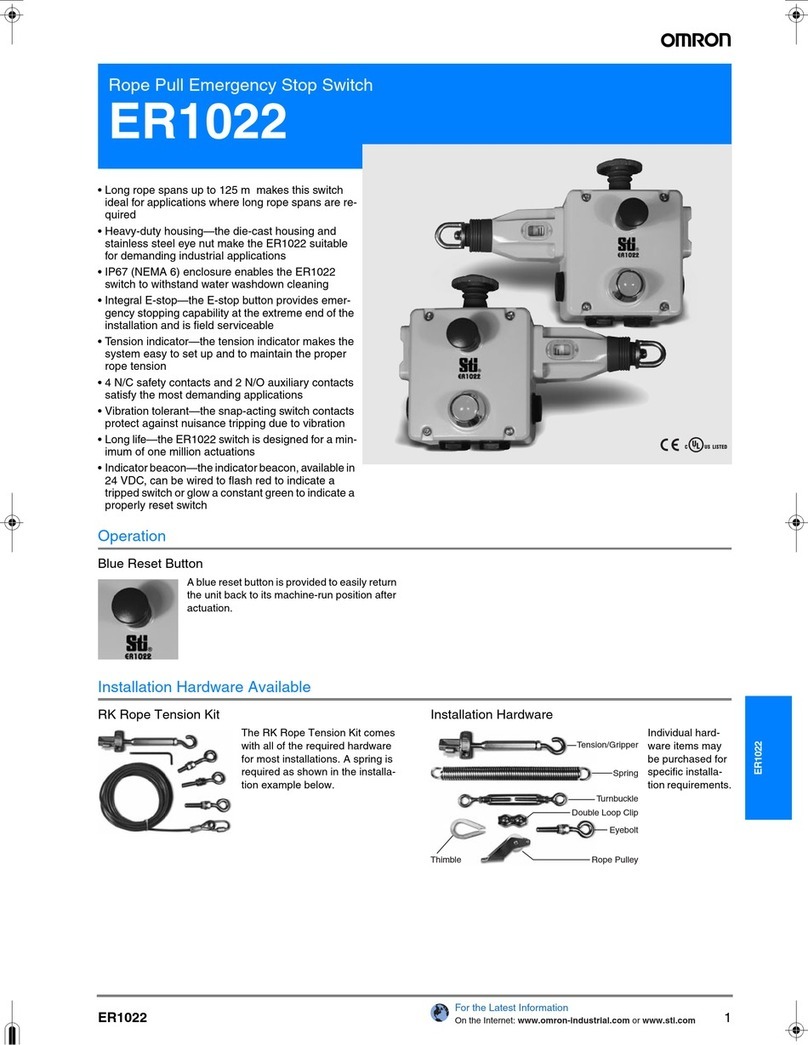

Tension Indicator

Indicator shown with steel rope properly adjusted.

1. Installation of all Safety Rope Switch systems must be in accordance with a risk assessment for the

individual application. Installation must only be carried out by competent personnel and in accordance

with these instructions.

2. Rope support eyebolts must be fitted at 2.5m. min. to 3m. max. intervals along all rope lengths

between switches. The rope must be supported no more than 500mm from the switch eyebolt or Safety

Spring (if used). It is important that this first 500mm is not used as part of the active protection coverage.

3. M5 mounting bolts must be used to fix the switches. Tightening torque for mounting bolts to ensure

reliable fixing is 4Nm. Tightening torque for the lid screws, conduit entry plugs and cable glands must be

1.5Nm to ensure IP seal. Only use correct sizing glands for conduit entry and cable outside diameter.

Exclusion of Liability Under the Following Circumstances

- incorrect use

- non-compliance with safety regulations

- installation and electrical connection not performed by authorized

personnel.

- failure to perform functional checks.

EC Declaration of Conformity

The manufacturer named below herewith declares that the product fulfills

the provisions of the directive(s) listed below and that the related standards

have been applied.

OMRON Robotics and Safety Technologies, Inc.

4225 Hacienda Drive, Pleasanton, CA 94588 USA

Directives applied:

Machinery directive 2006/42/EC

RoHS directive 2011/65/EC & 2015/863/EU

Standards applied:

EN 60947-5-1:2017

EN 60947-5-5:1998+/- A2:2017

EN 60204-1:2018

Pleasanton, CA 94588

Hank Liu

Quality Representative and Authorized Signatory

The signed EC Declaration of Conformity is included with the product.

Mechanical Reliability B10d: 1.5 x 106operations at 100mA load

ISO 13849-1: Up to PLe depending upon system architecture

Safety Data - Annual Usage: 8 cycles per hour/24 hours per day/365 days

PFHd: <1.0 x 10-7

Proof Test Interval (Life): 21 years

MTTFd: 214 years

Enclosure / Cover: Die-cast – painted yellow

External Parts Stainless steel

IP Rating IP67

Rope Spans Max ER1022, ER1032 (heavy duty), dual head 200m.,

single head 125m.

ER6022 (standard duty) = 80m.

ER5018 (mini duty) = 100N

Torque settings Mounting = M5 4.0 Nm

Lid = Torx M4 1.5 Nm

Terminals = 1.0 Nm

Ambient Operating Temperature -25C. to 80 C.

Vibration resistance 10-500Hz 0.35mm

Shock resistance 15g 11ms

Tension Force (typical mid setting) ER1022, ER1032 (Heavy Duty) 130N

ER6022 (standard duty) = 80m.

ER5018 (mini duty) = 100N

Typical Operating Force(Rope pulled) < 125N.< 300mm deflection

Mechanical Life: 1,000,000 operations

Weight ER1022, ER1032 (Heavy Duty) 130N

ER6022 (standard duty) = 80m.

ER5018 (mini duty) = 100N

Electrical

Contact Type: IEC 60947-5-1 Double break Type Zb Snap

Action up to 4NC (Safety positive break_ 2NO

(Auxiliary)

Contact Material: Silver

Termination: Clamp up to 2.5 sq. mm conductors

Approvals: cULus E195653, TUV Typed approved,

Certificate no: 968/EZ 350.02/19

Standards: See EC DofC, UL508 (NKCR, NKCR7)

ER Series

Operating Instructions for ER5018, ER6022, ER1022 & ER1032

4. Tensioning of rope is achieved by use of tensioner / gripper assemblies. Upon installation, tension to mid-position as indicated by the red arrows in the viewing

window of each switch. Check operation for all switches and the control circuits by puling the rope at various locations along the active protection area and resetting each

switch by depressing the Blue Reset button. Ensure each time that the switches latch off and require manual resetting by depressing the Blue Reset button. Increase the

system tension further, if required, depending upon the checks along the active length of coverage. If fitted with a Mushroom type E-Stop button (Red) then test and reset

each switch to ensure function of control circuits. Typical operational conditions for successful operation of system is less than 75N. pulling force and less than 150mm

deflection of rope between eyebolt supports.

5. Every week: Check correct operation of system at locations along all coverage length. Check for nominal tension setting, re-tension rope if necessary. Every 6

months: Isolate power and remove cover. Check screw terminal tightness and check for signs of moisture ingress. Never attempt to repair any switch.

OMRON Robotics and Safety Technologies, Inc.

4225 Hacienda Drive, Pleasanton, CA 94588 USA

www.omron247.com

©2020 All right reserved

Subject to technical modifications

Manual P/N 99918-0010 Rev.D

Information with regard to UL 508

Type 1 enclosures.

Use 16 - 12AWG coper conductors, rated 90°C minimum.

Intended for same polarity use and one polymeric conduit connection.

Electrical rating: A300 240Vac 3A (6,000 cycles).

120V 60A Making 6A. Breaking PF >0.38 (100,000 cycles).

240Vac 10A carry only.

Wire range: 16AWG - 12AWG copper. Torque 7lb/in. (0.8Nm).

LED powered by LVLC or Class 2 only.

Earth bonding terminal inside enclousre.