F-118 Enclosed Switch ZC-@55

Precautions

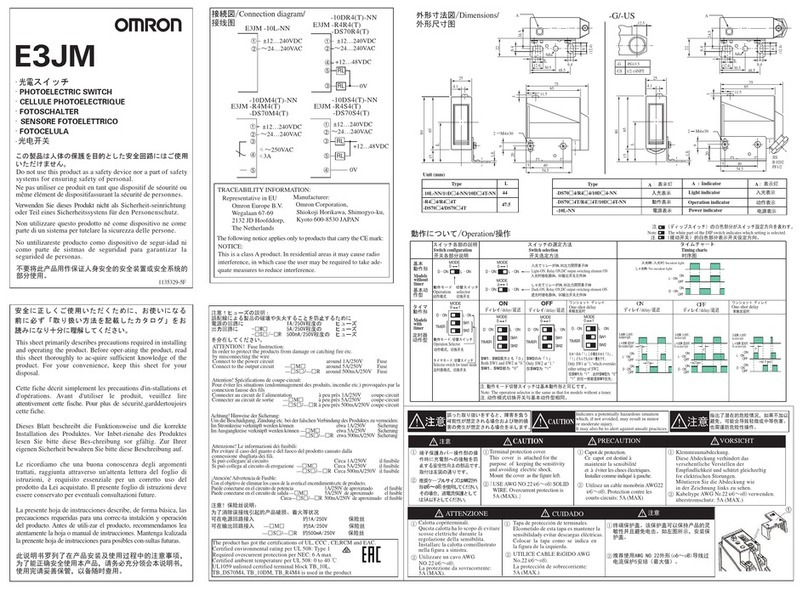

■Correct Use

Dog Angle

When operating the roller type, be sure to set the dog angle to less

than 30°(even when operating at a low speed). Operating the model

at a dog angle exceeding 30°will soon cause abrasion or damage.

Do not apply a twisting force to the plunger. Set the OT to 70% to

100% of the specified value so that the actuator will not exceed the

OT.

Handling

When detaching the Terminal Protective Cover, insert a screwdriver

and apply a force in the opening direction. Do not use excess force to

remove the cover. Doing so may cause deformation in the fitting sec-

tion and reduce the holding force.

When mounting the Terminal Protective Cover to the case, align the

cover on the case and then press the cover down to mount it firmly. If

the cover is pressed down in an inclined position, rubber packing will

deform and thus affect the sealing capability.

•A 8.5- to 10.5-dia. cable can be applied as seal rubber for the lead

wire outlet. (Use two- or three-core cable of VCT1.25 mm2.)

•Use weather-proof rubber (chloroprene rubber) as seal rubber for

the ZC-N22(21)55.

Mounting

•When mounting the Switch with screws on a side surface, fasten

the Switch with M4 screws and use washers, spring washers, etc.,

to ensure secure mounting.

Mounting Holes

•When mounting the Panel Mount-type Enclosed Switch (ZC-Q55,

ZC-Q2255, or ZC-Q2155) with screws on a side surface, remove

the hexagonal nuts from the actuator.

Mounting Hole Dimensions

Tightening Torque

A loose screw may result in a malfunction. Be sure to tighten each

screw to the proper tightening torque as shown below.

Operation

With the ZC-Q22(21)55, an appropriate OT line is marked on the

plunger. Set the OT so that it is between the two X-surface lines.

Micro-load Applicable Ranges

Using a standard load switch for opening and closing a micro-load

circuit may cause wear on the contacts. Use the switch within the

operating range. (Refer to the diagram below.) Even when using

micro-load models within the operating range shown below, if inrush

current occurs when the contact is opened or closed, it may cause

the contact surface to become rough, and so decrease life expect-

ancy. Therefore, insert a contact protection circuit where necessary.

The minimum applicable load is the N-level reference value. This

value indicates the malfunction reference level for the reliability level

of 60% (λ60). The equation λ60 = 0.5 ×10−6/operations indicates that

the estimated malfunction rate is less than 1/2,000,000 operations

with a reliability level of 60%.

Screwdriver

Terminal Protective Cover

Rubber packing Rubber packing

Two, 4.3-dia. or M4 screw holes

No. Type Torque

1 Terminal screw 0.78 to 1.18 N·m

2 Panel mounting screw 4.90 to 7.84 N·m

3 Side mounting screw 1.18 to 1.47 N·m

Model ZC-@55-01 ZC-@55

Minimum

applicable load 1 mA at 5 VDC 160 mA at 5 VDC

0

14.5+0.2dia.

Appropriate OT line

X-surface

30

24

12

5

0

1 10 100 1,0000.1

100 mA

1 mA

26 mA

0.8 W

100 mA 160 mA

Voltage (VDC)

Operating area for

ZC-@55-01 micro-

load models

Operating

area for

ZC-@55

standard

models

Current (mA)

Unusable

area

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C025-E1-09