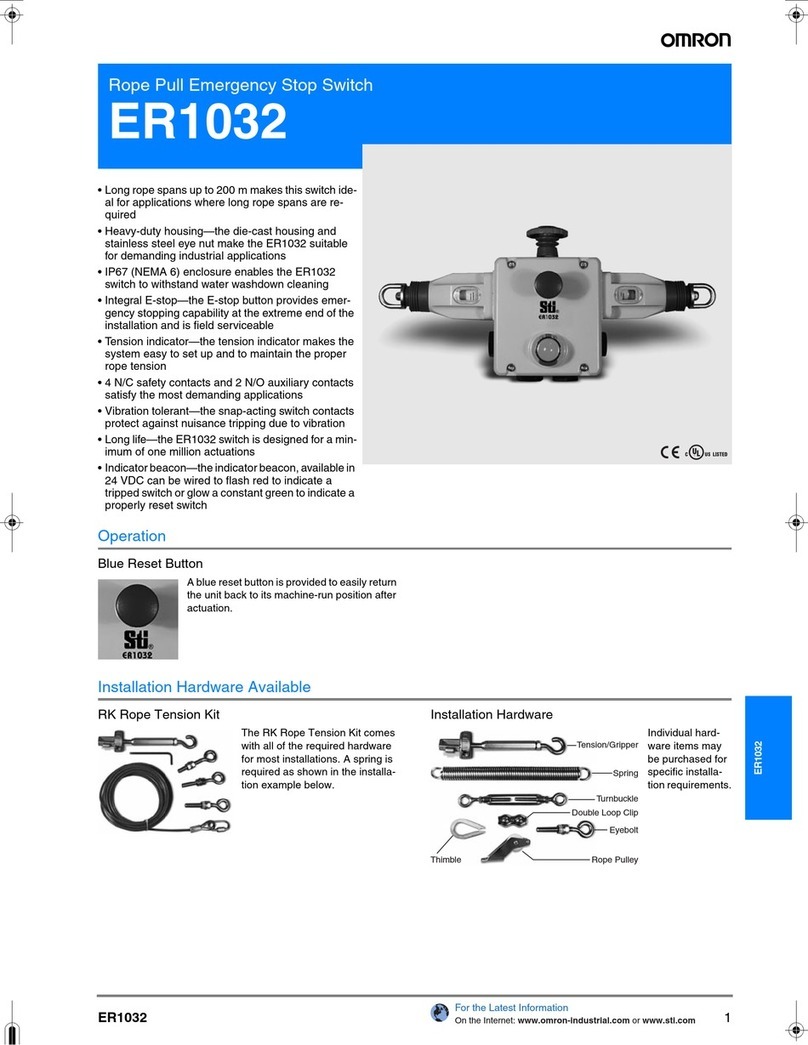

4Compact Rope Pull Emergency Stop Switch

For the Latest Information

On the Internet: www.omron-industrial.com or www.sti.com

Safety precautions

Operating instructions

Installation must be in accordance with the following steps and stated

specifications and should be carried out by suitably competent personnel.

Adherence to the recommended maintenance instructions forms part of

the warranty.

!WARNING Do not defeat, tamper, remove or bypass this unit.

Severe injury to personnel could result.

W

!WARNING

1.Installation of all Safety Rope Switch systems must be in accordance

with a risk assessment for the individual application. Installation must

only be carried out by competent personnel and in accordance with

these instructions.

2.Rope support eyebolts must be fitted at 2.5 m. min. to 3 m. max. inter-

vals along all rope lengths between switches. The rope must be

supported no more than 500 mm from the switch eyebolt or Safety

Spring (if used). It is important that this first 500 mm is not used as part

of the active protection coverage.

3. M5 mounting bolts must be used to fix the switches. Tightening torque

for mounting bolts to ensure reliable fixing is 4 Nm. Tightening torque for

the lid screws, conduit entry plugs and cable glands must be 1.5 Nm to

ensure IP seal. Only use correct sizing glands for conduit entry and

cable outside diameter.

4. Tensioning of rope is achieved by use of tensioner / gripper assemblies.

Upon installation, tension to mid-position as indicated by the red arrows

in the viewing window of each switch. Check operation for all switches

and the control circuits by puling the rope at various locations along the

active protection area and resetting each switch by depressing the Blue

Reset button. Ensure each time that the switches latch off and require

manual resetting by depressing the Blue Reset button. Increase the sys-

tem tension further, if required, depending upon the checks along the

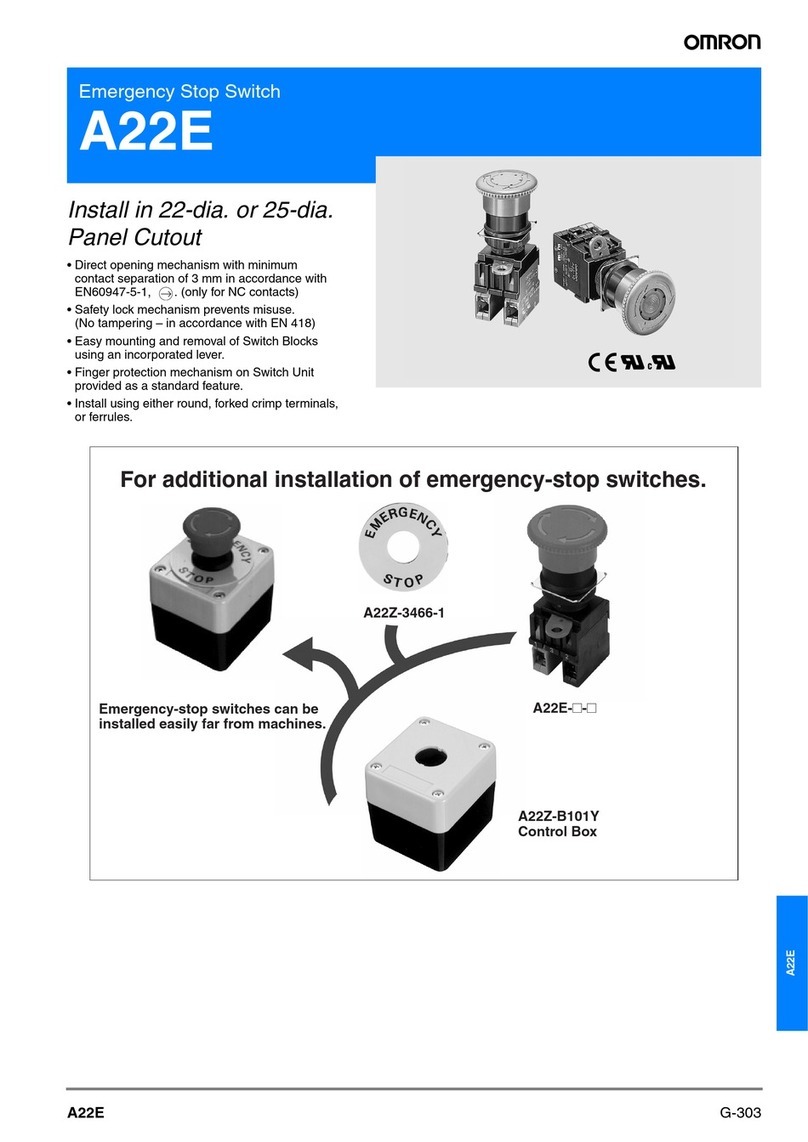

active length of coverage. If fitted with a Mushroom type E-Stop button

(Red) then test and reset each switch to ensure function of control cir-

cuits. Typical operational conditions for successful operation of system

is less than 75 N. pulling force and less than 150 mm deflection of rope

between eyebolt supports. If the optional LED is fitted but is not used,

ensure that the conductors remain coiled and tied to the tie hole in the

LED flange.

5. Every week: Check correct operation of system at locations along all

coverage length. Check for nominal tension setting, re-tension rope if

necessary. Every 6 months: Isolate power and remove cover. Check

screw terminal tightness and check for signs of moisture ingress. Never

attempt to repair any switch.

(120VAC)

(120VAC) Green

Red (common )

Black

Red

Green

Black

(+24VDC)

(+24VDC)

Optional 24 VDC Indicator Beacon

When +24VDC is applied to the red wire, the beacon will illuminate red

and flash.

When +24 VDC is applied to the green wire, the beacon will illuminate

green.

Optional 120 VAC Indicator Beacon

When +120VAC is applied to the red wire, the beacon will illuminate red

and flash.

When +120 VAC is applied to the green wire, the beacon will illuminate

green.

(0 V)

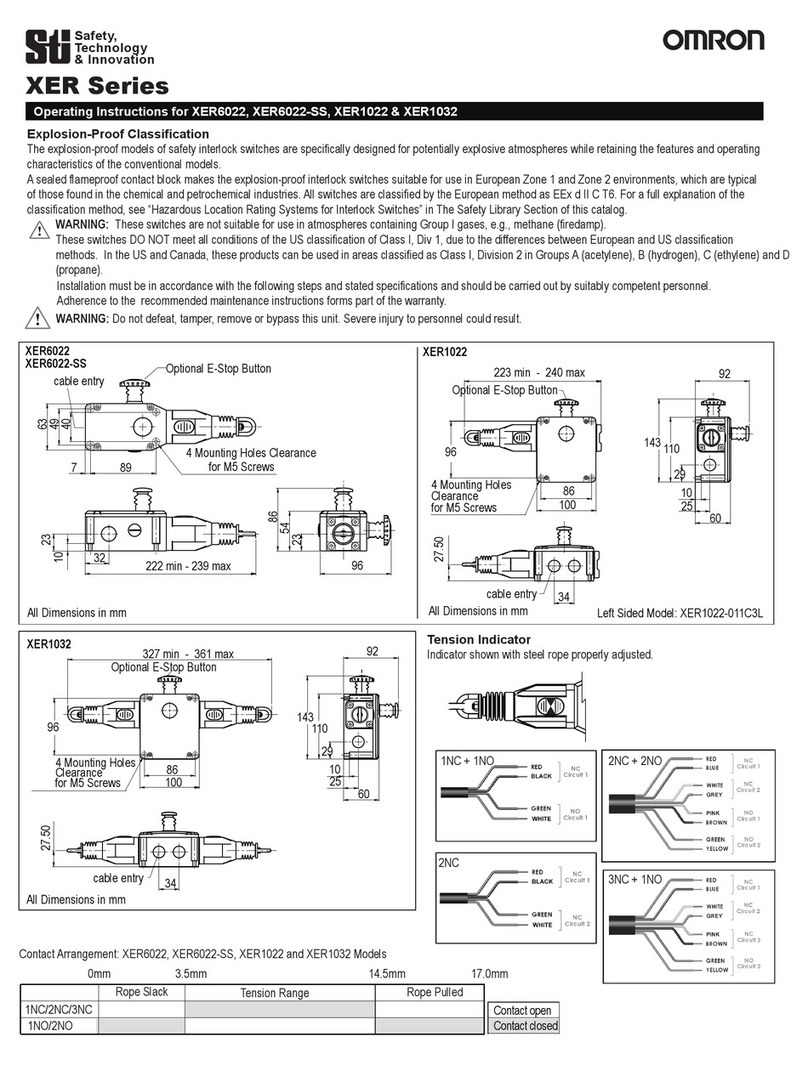

Tension Indicator

Indicator shown with steel rope properly adjusted.

In the interest of product improvement, specificationsare subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimetersinto inches, multiply by 0.03937. To convert gramsinto ounces, multiply by 0.03527.

Cat. No. E53E-EN-01

E53E-EN-01+ER5018+Datasheet.fm Seite 4 Freitag, 12. Oktober 2007 12:35 12