F-148 High-temperature Basic Switch TZ

Precautions

Refer to the Technical Information for Basic Switches (Cat. No. C122) for common precautions.

■Correct Use

Handling

The Switch has a ceramic casing. Do not drop the Switch from a

height of 30 cm or more. Doing so will break the casing.

Mounting

Be sure to turn OFF the power supply to the Switch before mounting,

dismounting, wiring, or working on the Switch for maintenance. Not

doing so may result in an electric shock or the Switch may burn.

Mount the switch with M3.5 stainless-steel screws with plane washer

and spring washers securely.

Use M3.5 stainless-steel mounting screws with plane washers or

spring washers to securely mount the Switch. Tighten the screws to

a torque of 0.69 to 0.98 N·m {7 to 10 kgf·cm}.

Mounting Holes

Connect nickel-plated solderless terminals to the TZ. Each terminal

must be secured on the TZ with M3.5 nut.

Make sure that the ceramic case is free of metal powder or other

impurities.

Operation

Do not modify the Actuator and change the operating position.

Make sure that the switching speed is not extremely slow or do not

use the Switch so that the pushbutton will be set to a position

between the FP and OP.

Make sure that the pin-type pushbutton and the switching stroke are

on the same vertical line.

Make sure that the switching frequency or speed is within the speci-

fied range.

•If the switching speed is extremely slow, the contact may not be

switched smoothly, which may result in a contact failure or contact

welding.

•If the switching speed is extremely fast, switching shock may dam-

age the Switch soon. If the switching frequency is too high, the con-

tact may not catch up with the speed.

The rated permissible switching speed and frequency indicate the

switching reliability of the Switch.

The life of a Switch is determined at the specified switching speed.

The life varies with the switching speed and frequency even when

they are within the permissible ranges. In order to determine the life

of a Switch model to be applied to a particular use, it is best to con-

duct an appropriate durability test on some samples of the model

under actual conditions.

Make sure that the actuator travel does not exceed the permissible

OT position. The operating stroke must be set to 70% to 100% of the

rated OT.

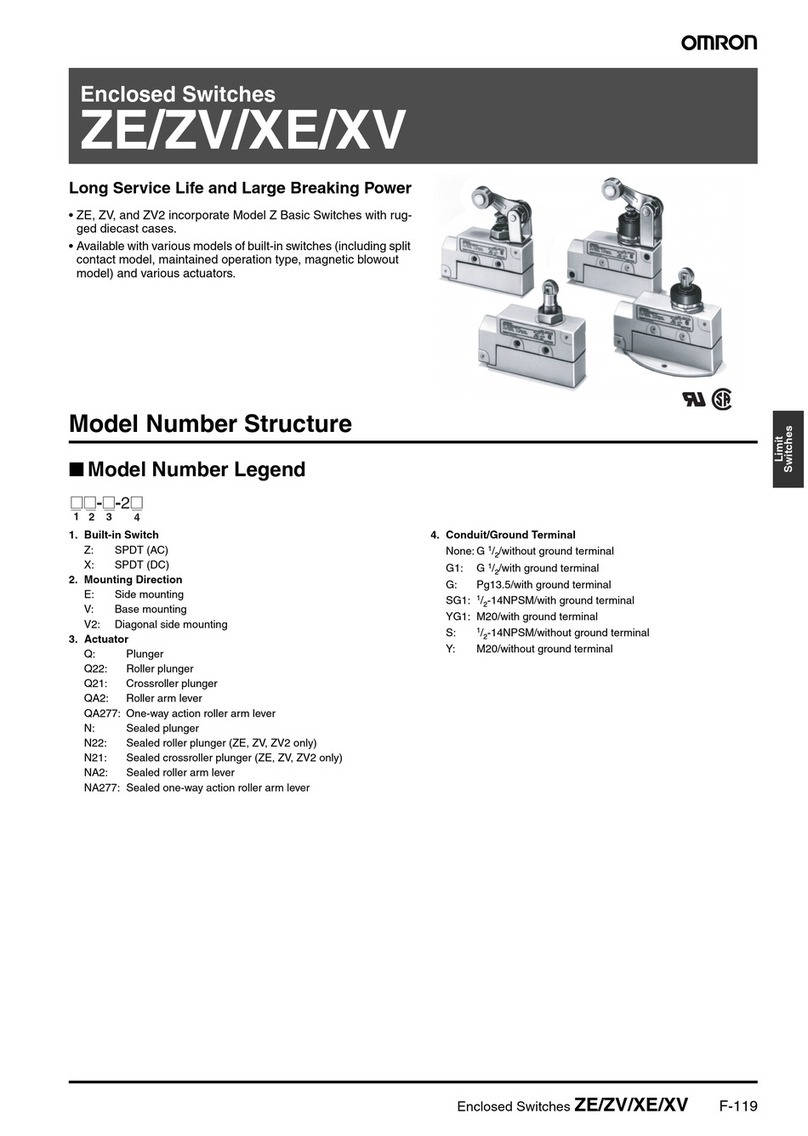

OF max.

RF min.

PT max.

OT min.

MD max.

1.27 N {130 gf}

0.2 N {20 gf}

2.6 mm

3.5 mm

1 mm

OP 28.6±1.2 mm

11.4

48.4R

Hinge Roller Lever

TZ-1GV2

(Stainless-steel lever)

9.5 dia. 4 (stainless-steel roller)

Three, M3.5

Two, 3.56-dia.

holes

25.4 ±0.1

Two, 3.56-dia. mounting holes or

M3.5 screw holes

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. B102-E1-02