OP S.r.l. 25131 BRESCIA - Via Serpente, 97 - Tel. 030/3580401 - Fax 0303580838

⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯

5

DICHIARAZIONE DI CONFORMITA’

DECLARATION OF CONFORMITY

2006/42/CE Nuova direttiva per la marcatura CE

( Abrogazione della direttiva 98/37/CE ex 89/392/CEE )

2006/42/CE New machinery directive for the CE

( Abrogation of Directives 98/37/CE ex 89/392/CEE )

NOI –WE OP S.r.l.

( Nome del fabbricante o del suo mandatario stabilito nella comunità - Supplier’s name)

Via del Serpente, 97 - 25131 BRESCIA

( Indirizzo completo - Address)

DICHIARIAMO SOTTO LA NOSTRA ESCLUSIVA RESPONSABILITA’ CHE IL PRODOTTO :

DECLARE UNDER OUR SOLE RESPONSIBILITY THAT THE PRODUCT :

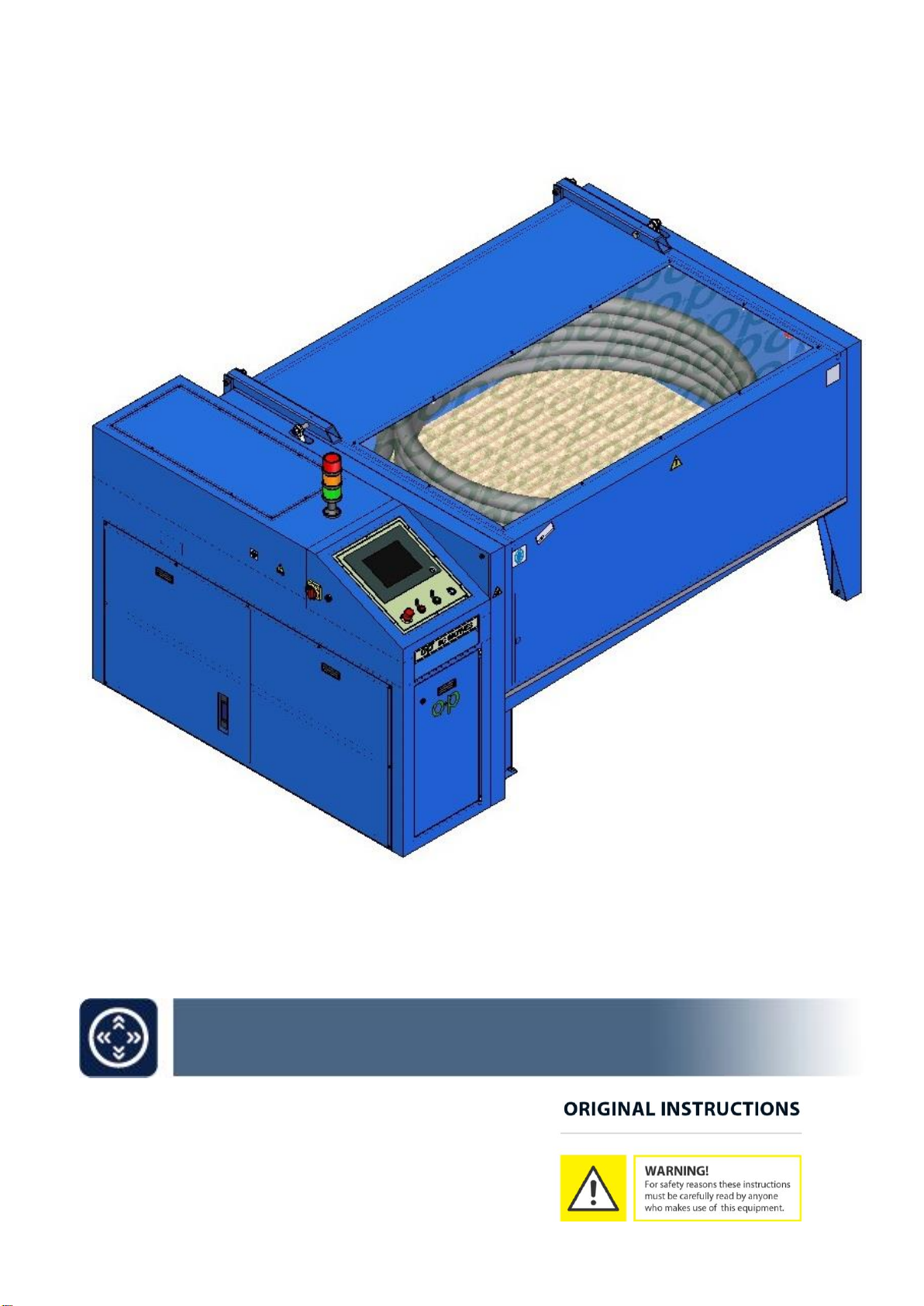

BC800/WES

( nome - name, tipo - type, modello - model / n° di serie - serial number )

• La macchina non rientra nell’elenco contenuto nell’All. IV della Direttiva Macchine 2006/42/CE

The machine is not part of the list included in Ann. IV Machinery Directive 2006/42/CE.

• La macchina rispetta i requisiti essenziali di sicurezza indicati sulla Direttiva Macchine e successive modifiche:

The machine follows the safety requirements included in the Machinery Directive and its following modifications:

2006/42/CE DIRETTIVA MACCHINE

2006/42/EC MACHINE DIRECTIVE

2014/35/EU DIRETTIVA BASSA TENSIONE

2014/35/UE LOW VOLTAGE DIRECTIVE (LVD)

2014/30/EU DIRETTIVA COMPATIBILITA’ ELETTROMAGNETICA

2014/30/UE ELECTROMAGNETIC COMPATIBILITY (EMC)

• La macchina è provvista di marcatura CE

The machine is provided with EC mark

• Norme di riferimento applicate:

Applied references normative:

UNI EN ISO 12100:2010 CEI EN 60204-1

UNI EN ISO 12100:2010 CEI EN 60204-1

IL LEGALE RAPPRESENTANTE

THE LEGAL REPRESENTATIVE

Brescia, lì DANIELE PIANTONI

(nome e firma o timbratura della persona autorizzata)

(name and signature or equivalent marking of authorized person)

Dichiariamo che il Fascicolo Tecnico è costituito presso OP s.r.l Via del Serpente 97, 25131 BRESCIA

We declare that the technical documentation is established c/o OP s.r.l. Via del serpente 97, 25131 BRESCIA

La persona responsabile del fascicolo tecnico è il Sig. Massimo Ziliani Resp. Uffi cio Tecnico.

Our technical manager, Mr. Massimo Ziliani, is responsible for the technical dossier