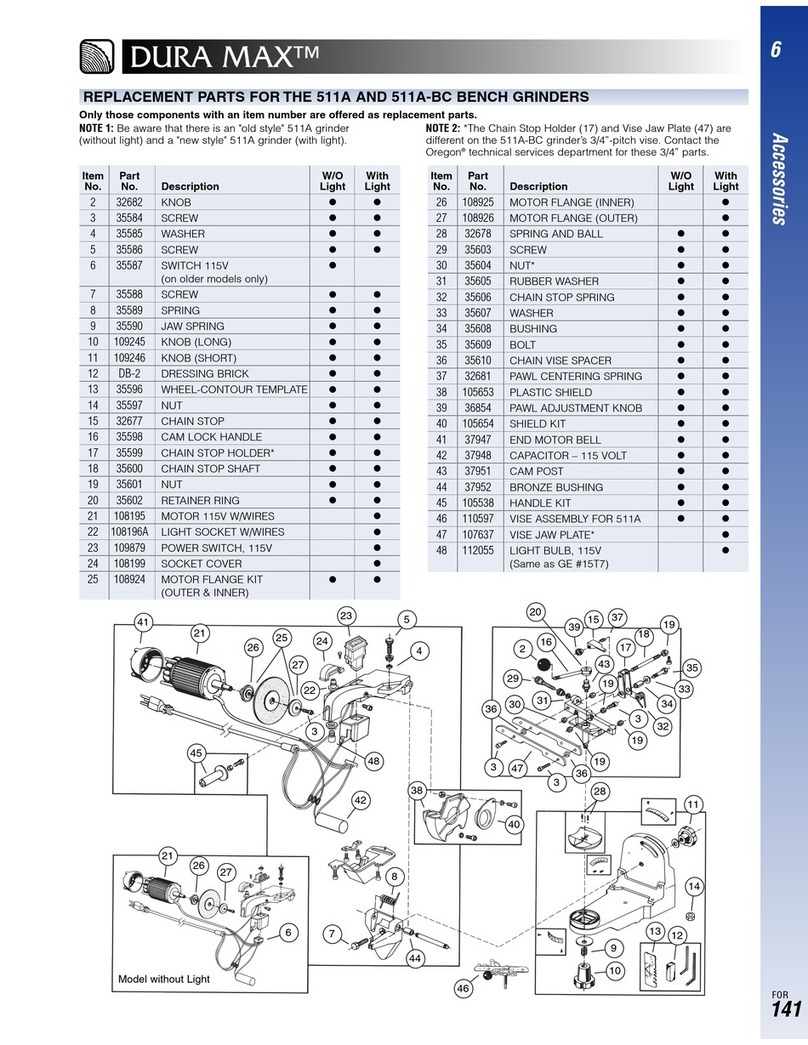

INTRODUCTION

1122..KKeeeeppwwoorrkkaarreeaacclleeaann..Cluttered areas and

benches invite accidents. Make sure that the working

area of the grinding wheel is free of tools or other

objects before starting up the grinder. Frequently

clean grinding dust from beneath the grinder.

1133..DDoonn’’ttuusseeiinnaaddaannggeerroouusseennvviirroonnmmeenntt..

Don’t use power tools in damp or wet locations,

or expose them to rain. Be sure to keep the work

area well lighted.

1144..CChheecckktthheeppoossiittiioonnoofftthheeppoowweerrccoorrdddduurriinngg

ooppeerraattiioonn,,making sure that it remains outside the

range of action of the grinding wheel and is not

under tension. Never operate in the vicinity of

other electrical cables/cords.

1155..MMaakkeewwoorrkksshhooppcchhiillddpprrooooffwith padlocks and

master switches. Also, do not allow anyone but

the operator to touch the power cord or remain in

the close vicinity of the grinder while operating.

1166..AAllwwaayysskkeeeepptthheehhaanndd--ggrriippsscclleeaannaannddddrryy..

1177..BBeeffoorreessttaarrttiinnggtthheeggrriinnddeerr,,mmaakkeessuurreetthhaatttthhee

ggrriinnddiinnggwwhheeeelliissccoorrrreeccttllyysseeccuurreeddand positioned

in the up, rest position. Do not over-tighten the

wheel mounting flange nut.

1188..SSeeccuurreewwoorrkk..Make sure that the grinder is

secured as shown in Figures 1-3, page 6. Use the

vise to hold the chain. It frees both hands for mov-

ing the grind head/wheel down to grind the chain.

1199..DDoonn’’ttoovveerrrreeaacchh..Keep proper footing and

balance at all times.

2200..NNeevveerrssttaannddoonnaannuunnssttaabblleeppllaattffoorrmm..

Always work in a stable and safe position. Serious

injury could occur if the grinder is tipped or if the

cutting tool is unintentionally contacted.

2211..CChheecckkffoorrddaammaaggeeddppaarrttss..Before using the

grinder, check to make sure that all the devices,

those for safety and others, are in good working

order and free from any obvious damage that could

affect performance and safety/reliability during use.

2222..UUsseerreeccoommmmeennddeeddaacccceessssoorriieess..Consult the

owner’s manual for recommended accessories.

The use of improper accessories may cause risk

of injury. Use only flanges furnished with the

grinder. To guarantee the efficient and consistent

operation of your grinder, remember that any

worn or broken parts must be replaced using only

original spare parts.

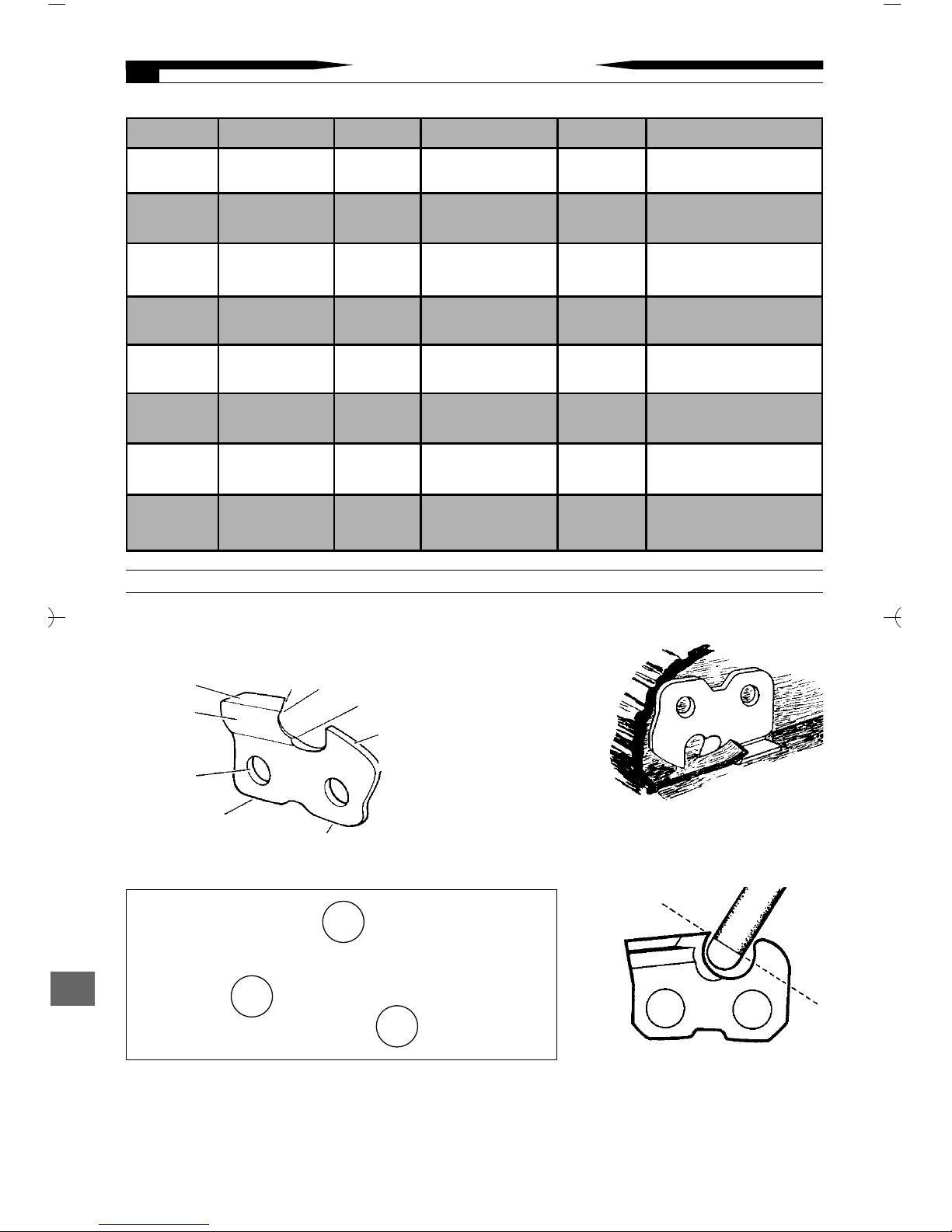

2233..UUsseeoonnllyyrreeccoommmmeennddeeddggrriinnddiinnggwwhheeeellss,,as

specified on page 13, table 2.

2244..CChheecckkyyoouurrggrriinnddeerr..Never work with a

damaged, poorly repaired, incorrectly fitted, or

modified grinder. Do not remove, damage, or

disable any safety devices.

2255..AAllwwaayyssuusseetthheerriigghhttttoooollffoorrtthheejjoobb. Never

use the grinder to cut or grind objects other than

saw chains. Don’t force grinder or attachment to

do a job for which it was not designed.

2266..MMaaiinnttaaiinnttoooollsswwiitthhccaarree..Keep tools sharp

and clean for best and safest performance.

Follow instructions for lubricating and changing

accessories.

2277..NNeevveerrlleettyyoouurrggrriinnddeerrbbeeeexxppoosseeddttoorraaiinnoorr

ddaammppnneessss..

2288..NNeevveerruusseetthheeggrriinnddeerriinnaanneexxpplloossiivveeoorr

ffllaammmmaabblleeaattmmoosspphheerree..

2299..AAllwwaayyssccoonnssuullttyyoouurrddeeaalleerrfor any clarification

or important maintenance or repair operation.

3300..NNeevveerrjjeerrkktthheeccaabblleettooddiissccoonnnneeccttiittffrroommtthhee

oouuttlleett..Keep the cable/cord away from heat, oil,

and sharp objects.

3311..UUsseepprrooppeerreexxtteennssiioonnccoorrdd..Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current you will need to

perform your grinding operation. An undersized

cord will cause a drop in line voltage resulting in

loss of power and overheating. Table 1, page 8,

shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt,

use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

3