710-120

2

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . 3

1.1 Important user information. . . . . . . . . .3

1.2 About this manual . . . . . . . . . . . . . . . 3

1.3 Intended use . . . . . . . . . . . . . . . . . . 3

1.4 Nameplate . . . . . . . . . . . . . . . . . . . 4

1.5 Recycling information . . . . . . . . . . . . .4

2 Safety . . . . . . . . . . . . . . . . . . . . 5

2.1 Explanation of warning levels . . . . . . . . 5

2.2 General machine safety warnings . . . . . . 5

2.3 Signs and symbols. . . . . . . . . . . . . . .7

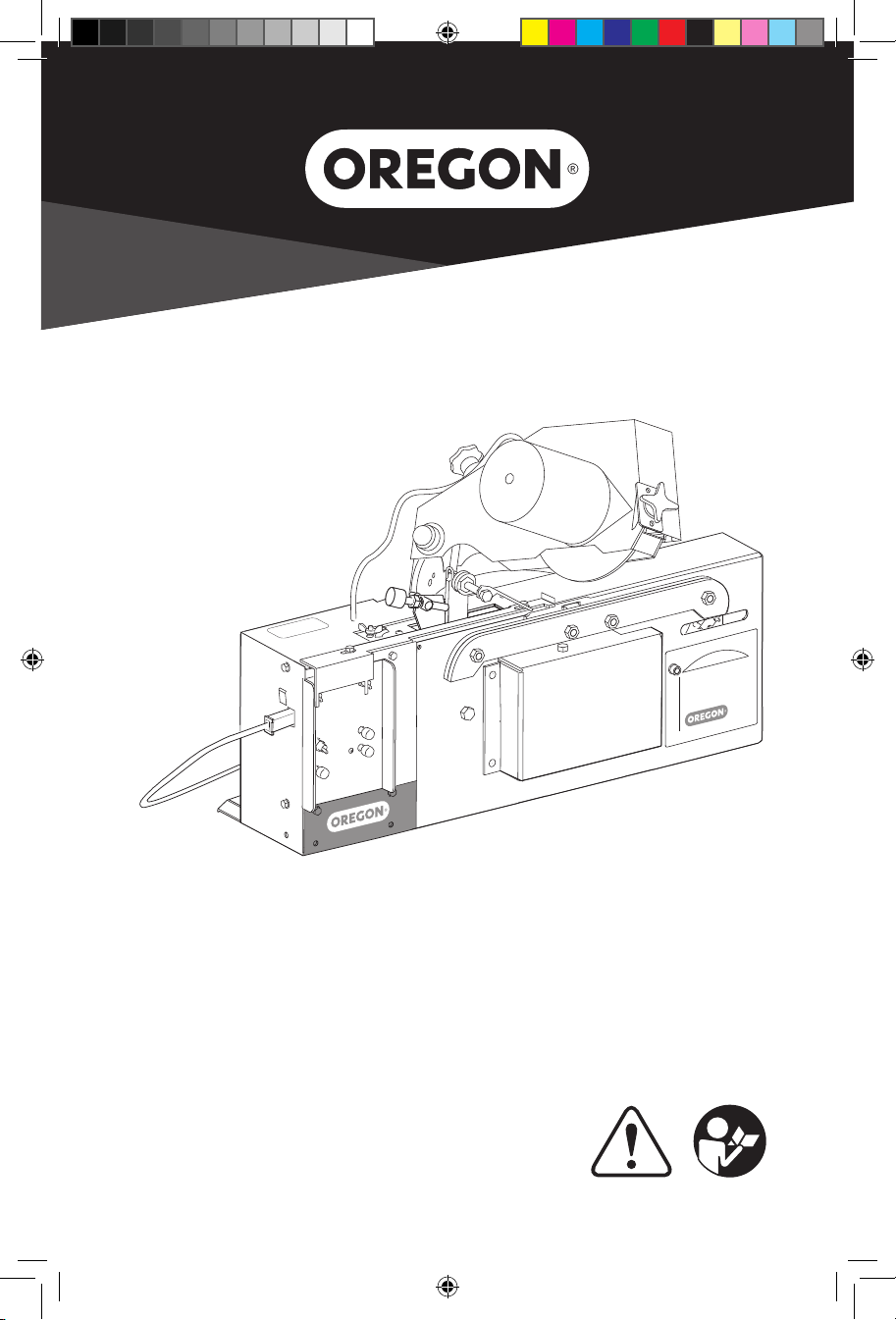

3 Product Description . . . . . . . . . . . . 8

3.1 Product overview . . . . . . . . . . . . . . . 8

3.2 Front view . . . . . . . . . . . . . . . . . . . 8

3.3 Back view. . . . . . . . . . . . . . . . . . . .9

3.4 Grinding head . . . . . . . . . . . . . . . . 10

3.5 Controls. . . . . . . . . . . . . . . . . . . . 11

3.5.1 Grinding speed knob . . . . . . . . . 12

3.6 Chain overview . . . . . . . . . . . . . . . . 12

3.7 Technical data . . . . . . . . . . . . . . . . 13

4 Installation . . . . . . . . . . . . . . . . 14

4.1 Safety during installation . . . . . . . . . . 14

4.2 Site requirements . . . . . . . . . . . . . . 14

4.3 Unpacking the machine . . . . . . . . . . . 14

4.4 Bench-mounting the machine . . . . . . . 15

4.5 Installing the grinding wheel . . . . . . . . 15

4.6 Test the machine before first use . . . . . 17

5 Operation. . . . . . . . . . . . . . . . . 18

5.1 Safety during operation . . . . . . . . . . . 18

5.2 Preparing for operation . . . . . . . . . . . 18

5.2.1 Preparing the grinding wheel . . . . 18

5.2.2 Setting the head-tilt angle . . . . . . 19

5.2.3 Setting the top-plate angle . . . . . . 19

5.2.4 Inserting the chain. . . . . . . . . . . 20

5.2.5 Making the grinding settings . . . . . 21

5.3 Operating the machine . . . . . . . . . . . 24

5.4 Depth gauge grinding . . . . . . . . . . . . 25

© Blount, Inc. Pricing and specifications subject to change without notice. All rights reserved.

Oregon® and Low Profile™ are trademarks of Blount, Inc. in the United States and/or in other countries.

6 Maintenance and Service . . . . . . . . 27

6.1 Safety during maintenance . . . . . . . . . 27

6.2 Frequency of maintenance . . . . . . . . . 27

6.3 Changing the grinding wheel and fitting

the grinding wheel guard . . . . . . . . . . 28

6.4 Fastening the chain vise. . . . . . . . . . . 29

6.5 Checking and adjusting the wire . . . . . . 29

6.6 Service . . . . . . . . . . . . . . . . . . . . 30

7 Troubleshooting . . . . . . . . . . . . . 31

7.1 Troubleshooting procedure . . . . . . . . .31

7.2 Sharpening test . . . . . . . . . . . . . . . 31

7.3 Issues . . . . . . . . . . . . . . . . . . . . . 32

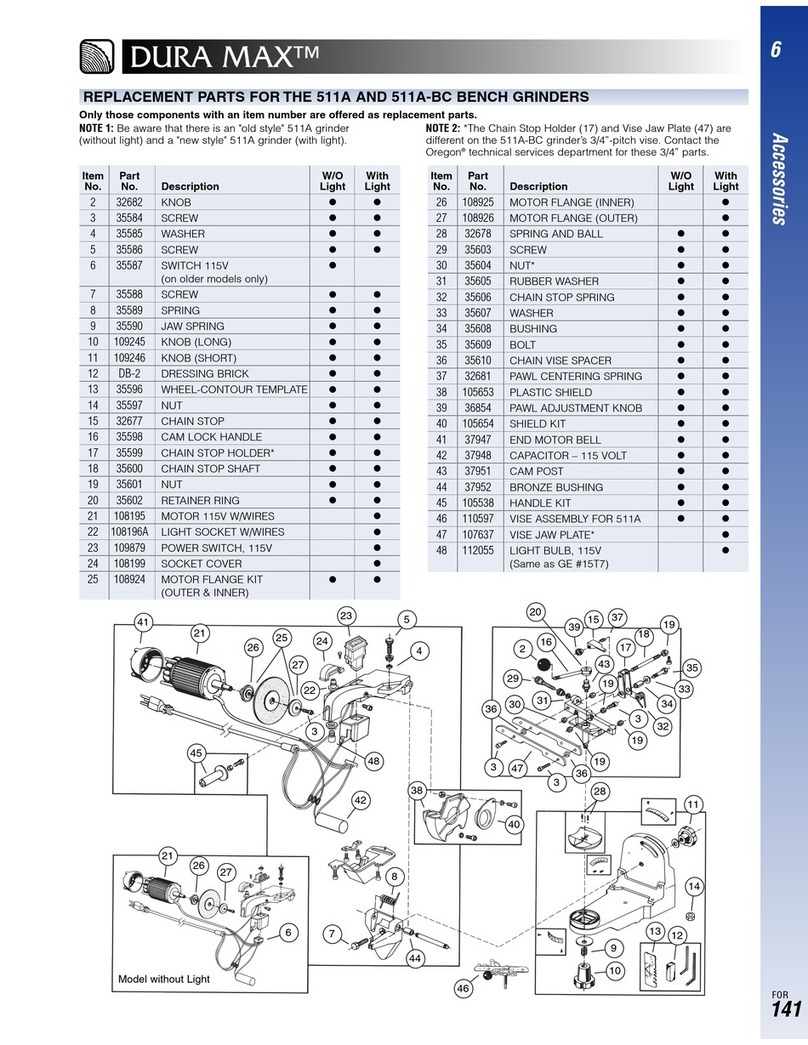

8 Accessories and Spare Parts. . . . . . 33

8.1 Ordering information . . . . . . . . . . . . 33

8.2 List of accessories. . . . . . . . . . . . . . 33

8.3 Spare parts . . . . . . . . . . . . . . . . . . 34

8.4 Converter . . . . . . . . . . . . . . . . . . 37

8.5 Stand . . . . . . . . . . . . . . . . . . . . . 38

8.6 Pneumatic chain tensioner . . . . . . . . . 39

9 Instrumental Measurements . . . . . . 40

9.1 Assembling the stand . . . . . . . . . . . . 41

9.2 Assembling the pneumatic

chain tensioner. . . . . . . . . . . . . . . . 42

9.3 Using the chain tensioner . . . . . . . . . . 45

10 Warranty and Service. . . . . . . . . . 47

593357aa_AutoChainGrinder_710-120_OM.indd 2 3/1/17 12:03 PM