−2−

Table of contents

1 Safety precautions ............................... 3

2 Introduction ......................................... 4

3 Preparation ........................................... 5

3.1 Checking the product .........................................5

3.2 Names and functions of parts ..........................5

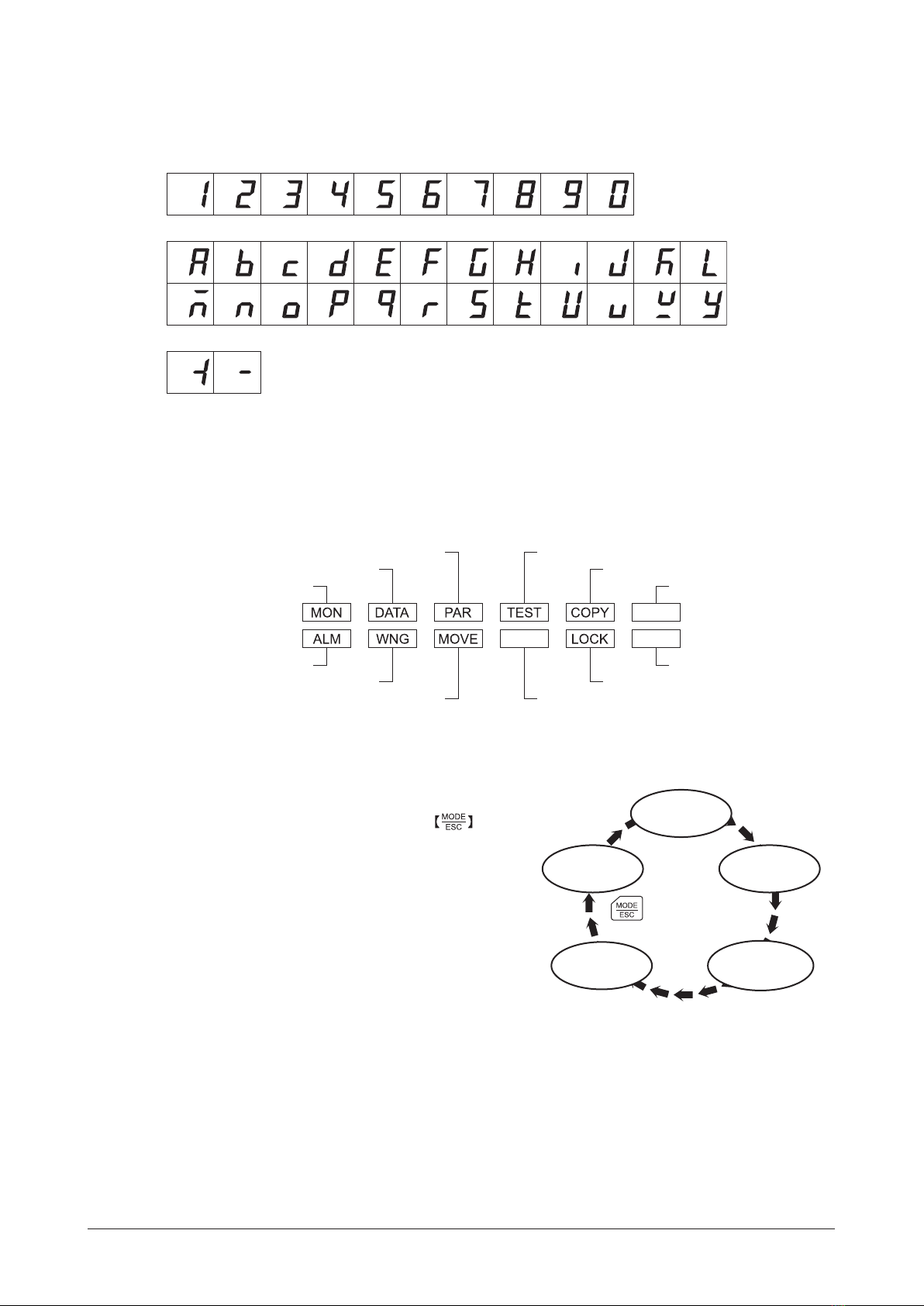

3.3 How to read the display .....................................6

3.4 How to read the LED indicators.......................6

3.5 Types of operation modes ................................6

3.6 Basic operations of the ....................7

3.7 Edit lock function..................................................8

3.8 Rewriting the drivers non-volatile

memory....................................................................9

4 Installation and connection of the

...............................................10

4.1 Location for installation .................................. 10

4.2 Installation method .......................................... 10

4.3 Connecting to the driver ................................ 11

4.4 Error display on screen ................. 11

5 Screen transitions ..............................12

6 Monitor mode .....................................18

6.1 Overview of the monitor mode ................... 18

6.2 Operation in the monitor mode .................. 18

6.3 Monitor items ..................................................... 19

7 Data mode ..........................................24

7.1 Operation in the data mode .......................... 24

7.2 Setting items ....................................................... 25

7.3 Setting example ................................................. 26

7.4 Initialization of the selected operation

data ......................................................................... 27

7.5 Initialization of all operation data ............... 27

8 Parameter mode .................................28

8.1 Operation in the parameter mode .............. 28

8.2 Setting example ................................................. 29

8.3 Parameter list ...................................................... 30

8.4 Initializing parameters ..................................... 37

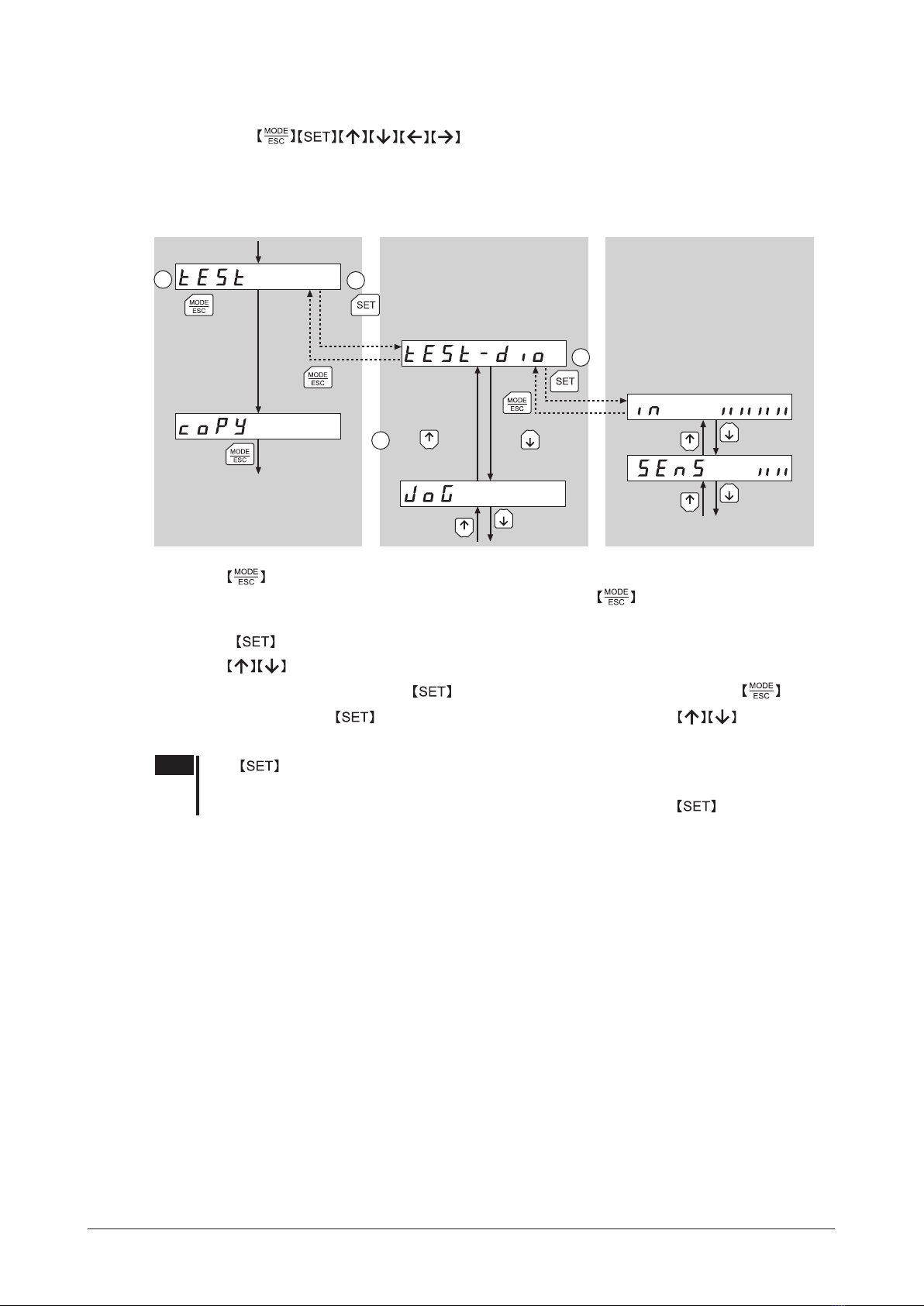

9 Test mode ............................................38

9.1 Overview of the test mode ............................ 38

9.2 Operation in the test mode ........................... 39

9.3 Direct I/O test ...................................................... 39

9.4 JOG operation .....................................................40

9.5 Data select operation ....................................... 41

9.6 Return-to-home operation ............................41

9.7 Presetting the position .................................... 41

9.8 Teaching ............................................................... 42

10 Copy mode ..........................................43

10.1 Overview of the copy mode .......................... 43

10.2 Operation in the copy mode ......................... 43

10.3 Downloading to the driver ............................ 44

10.4 Uploading to the

10.5 Verifying data ...................................................... 45

10.6 Initializing driver data ...................................... 46