Preparation

7

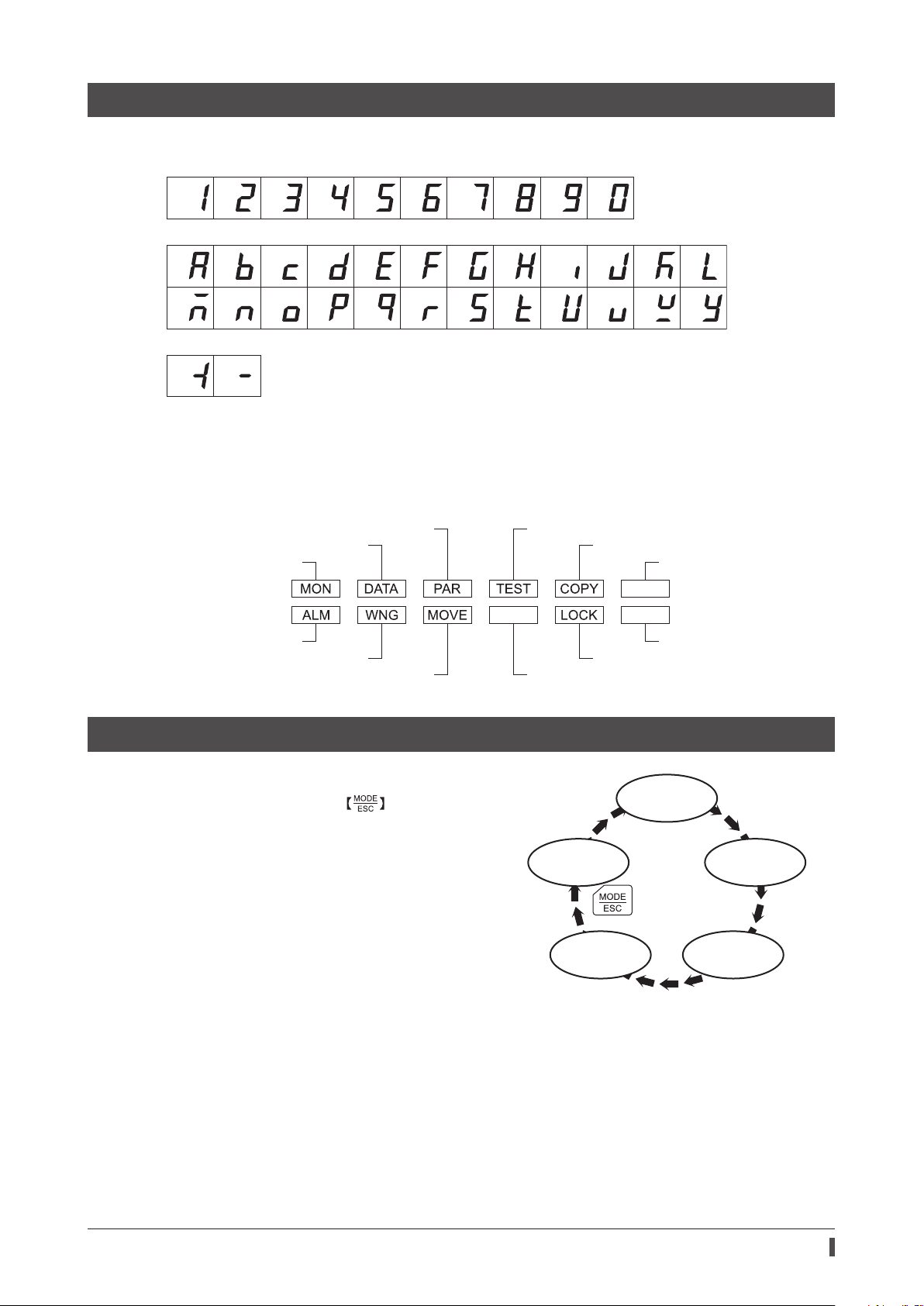

How to input values

As an example, how to change “+30” to “−100” is explained.

Basic operations

•Use the keys to increase/decrease the value or change the sign.

Use the keys to move to the digit you want to edit.

•If positive and negative values are dierentiated, each value is preceded by a sign.

•You can edit the digit currently blinking.

1. First, change the 10’s place from "3" to "0."

Press the key once to move to the 10’s digit you want to edit.

Once

or

Once

Once

Once

Once

2. Press the key three times to change the value to "0."

3. Next, change the 100’s place from "0" to "1."

Press the key once to move to the 100’s digit you want to edit.

4. Press the key once to change the value to "1."

5. Next, change the sign.

Press the key once to move to the sign digit you want to edit.

6. Press the or key once to change the sign to "−."

7. After all digits have been changed, press the key to conrm

the value.

All digits comprising the value blink for approx. 2 seconds.

If the value you have input is outside the setting range, "Error" will be displayed for 1 second.

If this error display appears, input a dierent value that falls within the setting range.

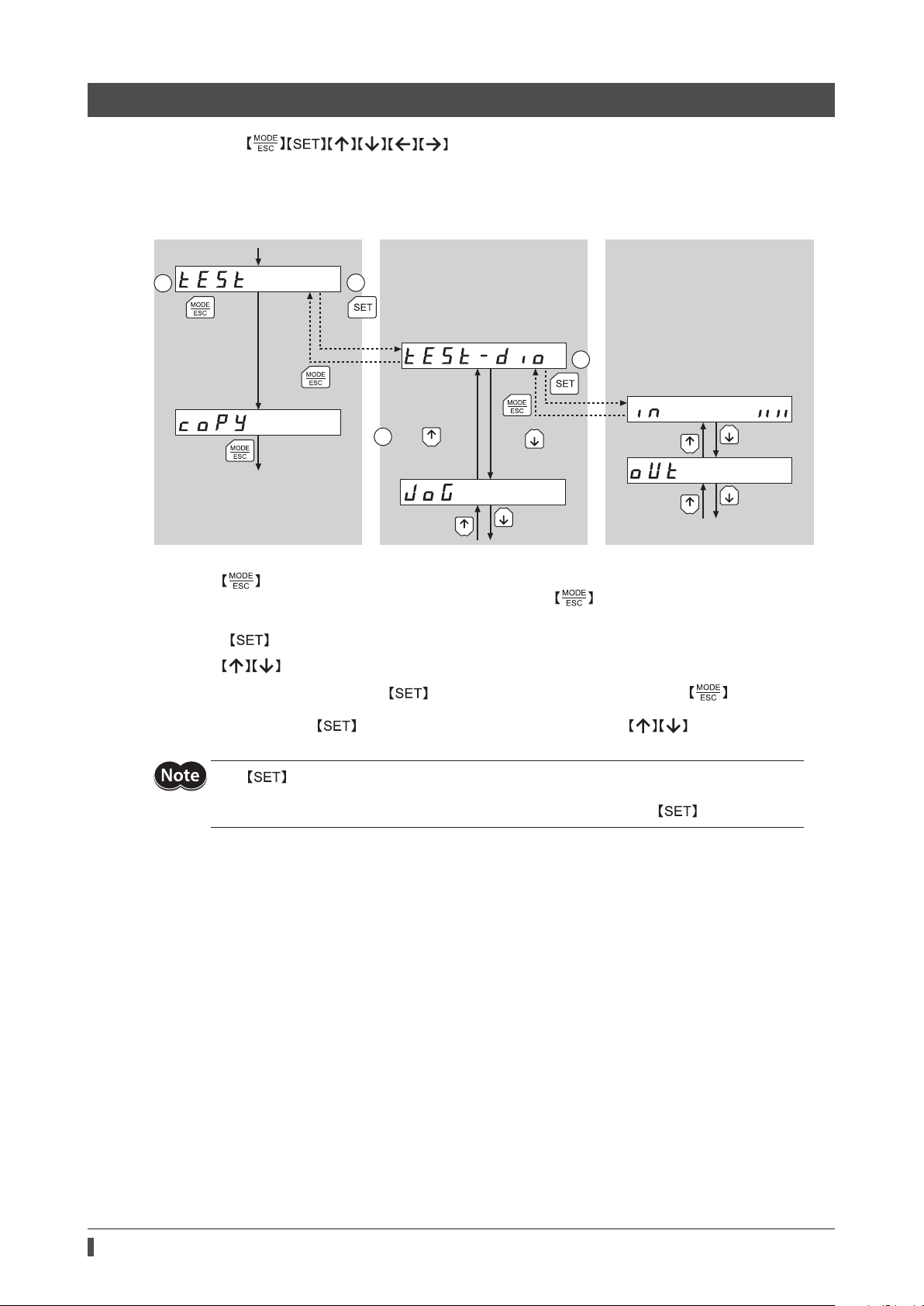

3-6 Edit lock function

Enable the edit lock function if you want to prevent operation data and parameters from being edited or cleared.

Operation data and parameters cannot be changed or deleted while the edit lock function is enabled.

zSetting the edit lock function

In the top screen of each operation mode, press the key for at least

5 seconds. The display will show "LocK" and the edit lock function will be enabled.

The "LOCK" LED in the LED indicator area will also be lit.

zCanceling the edit lock function

Again in the top screen of each operation mode, press the key for at least

5 seconds. The display will show "UnLocK" and the edit lock function will be

cancelled. The "LOCK" LED in the LED indicator area will turn o.

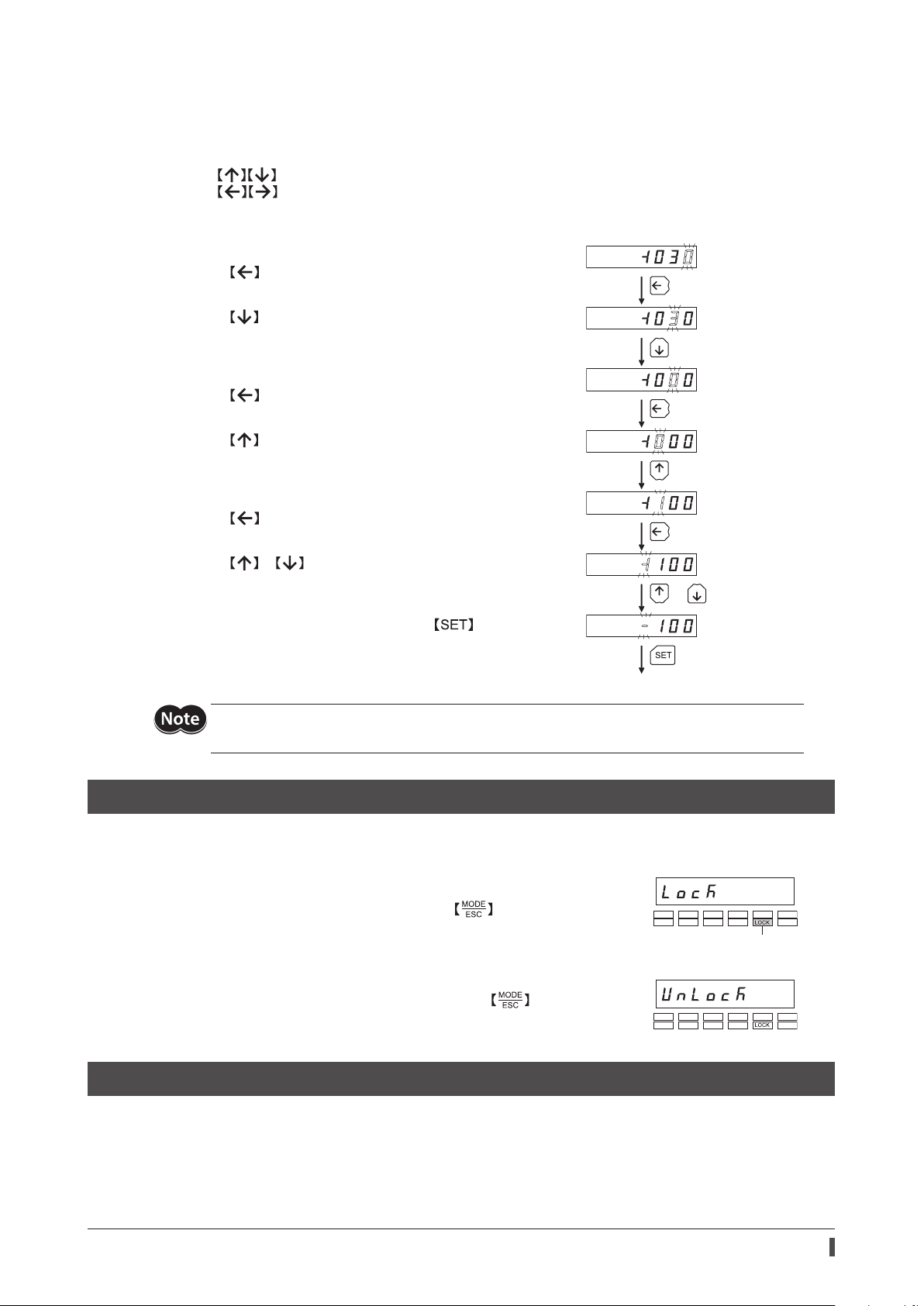

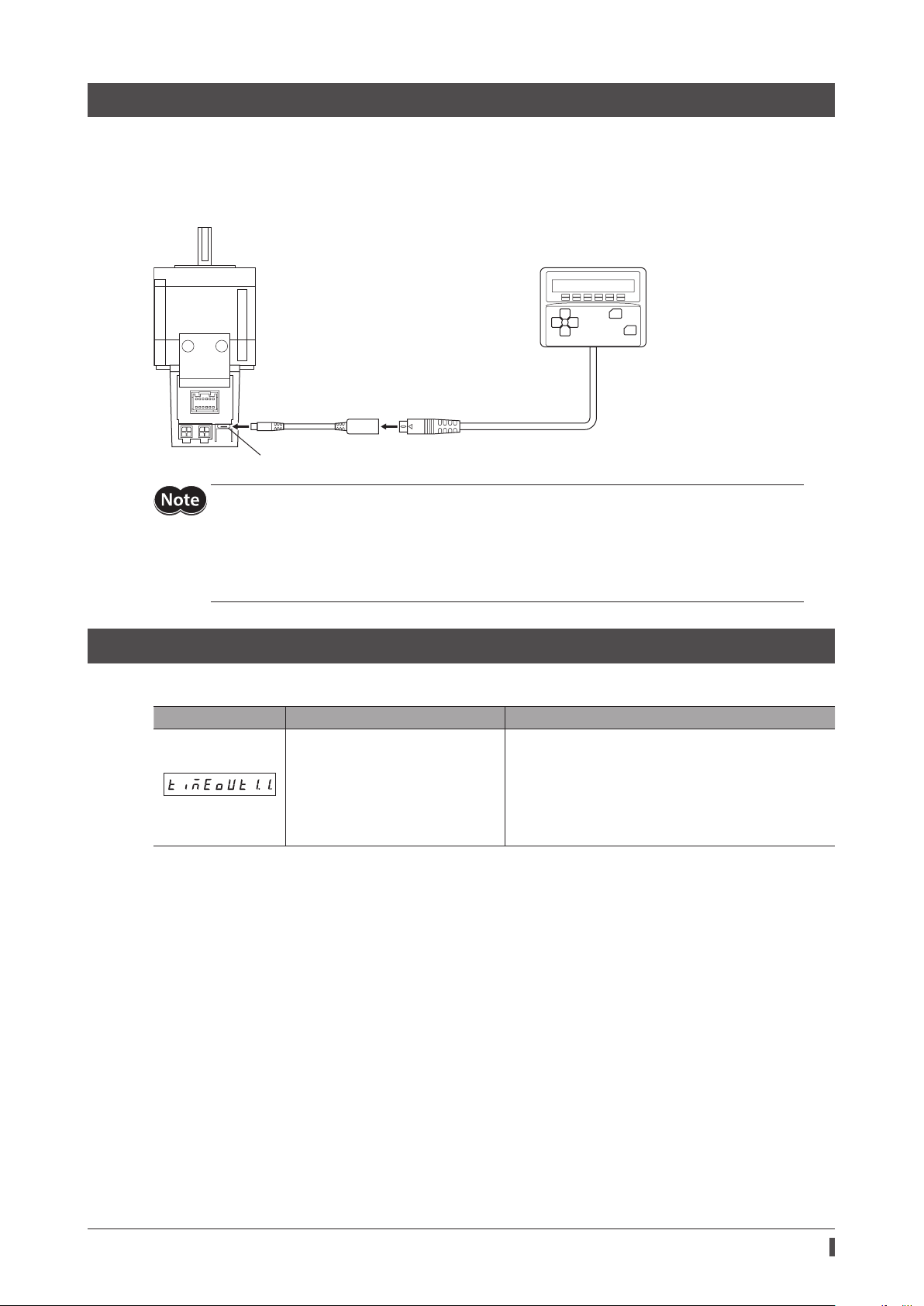

3-7 Rewriting the motor’s non-volatile memory

Operation data and parameters are saved to the motor’s non-volatile memory. The non-volatile memory can be

rewritten approximately 100,000 times. The non-volatile memory will be rewritten after one of the following

operations is performed:

•Edit any operation data or parameter

•Download data from the OPX-2A to the motor

•Initialize motor operation data and parameters