−2−

1 Safety precautions .............................. 3

2 Introduction ......................................... 4

3 Preparation .......................................... 5

3.1 Checking the product ............................... 5

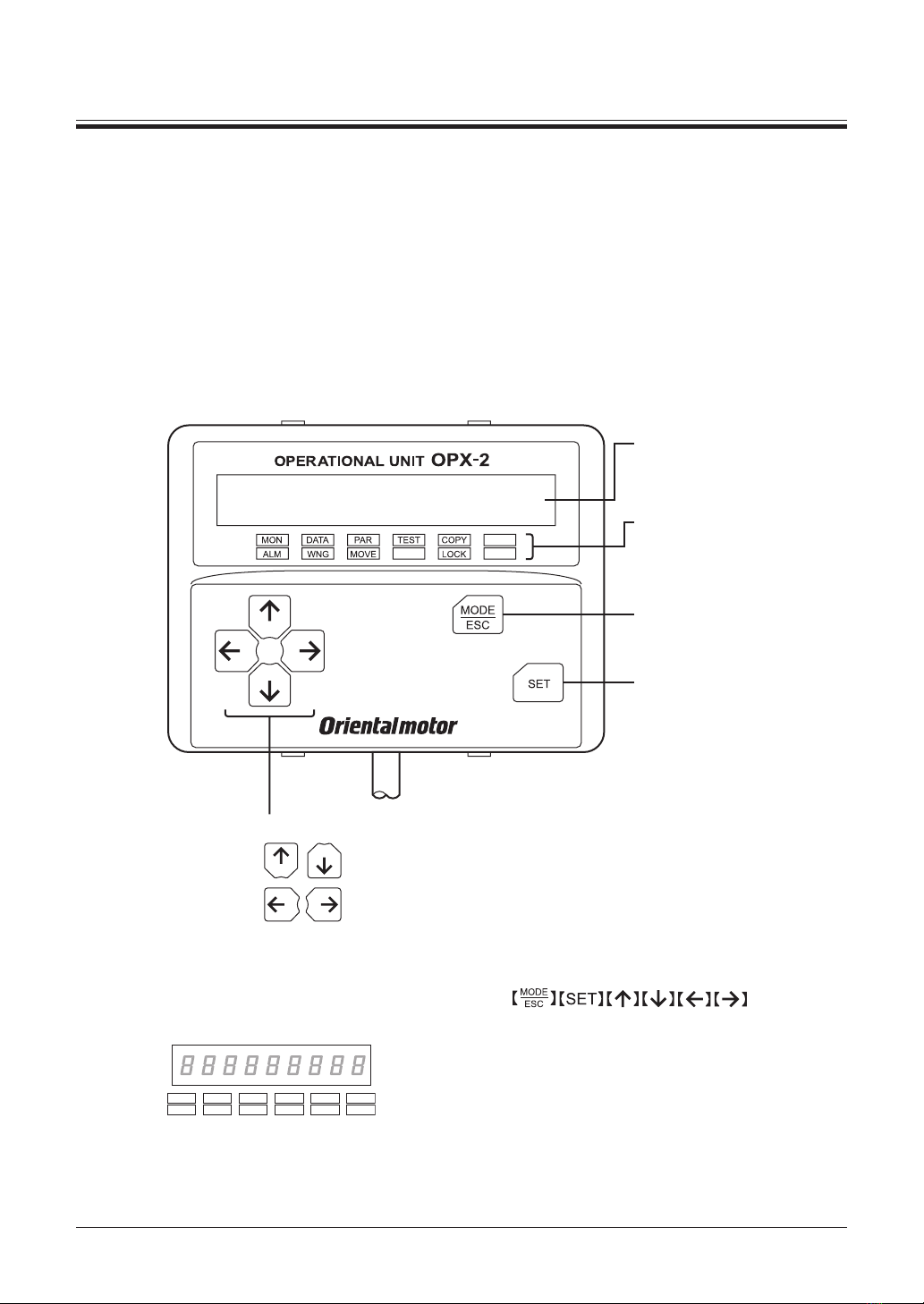

3.2 Names and functions of parts .................. 5

3.3 How to read the display ........................... 6

3.4 How to read the LED indicators ............... 6

3.5 Types of operation modes ....................... 6

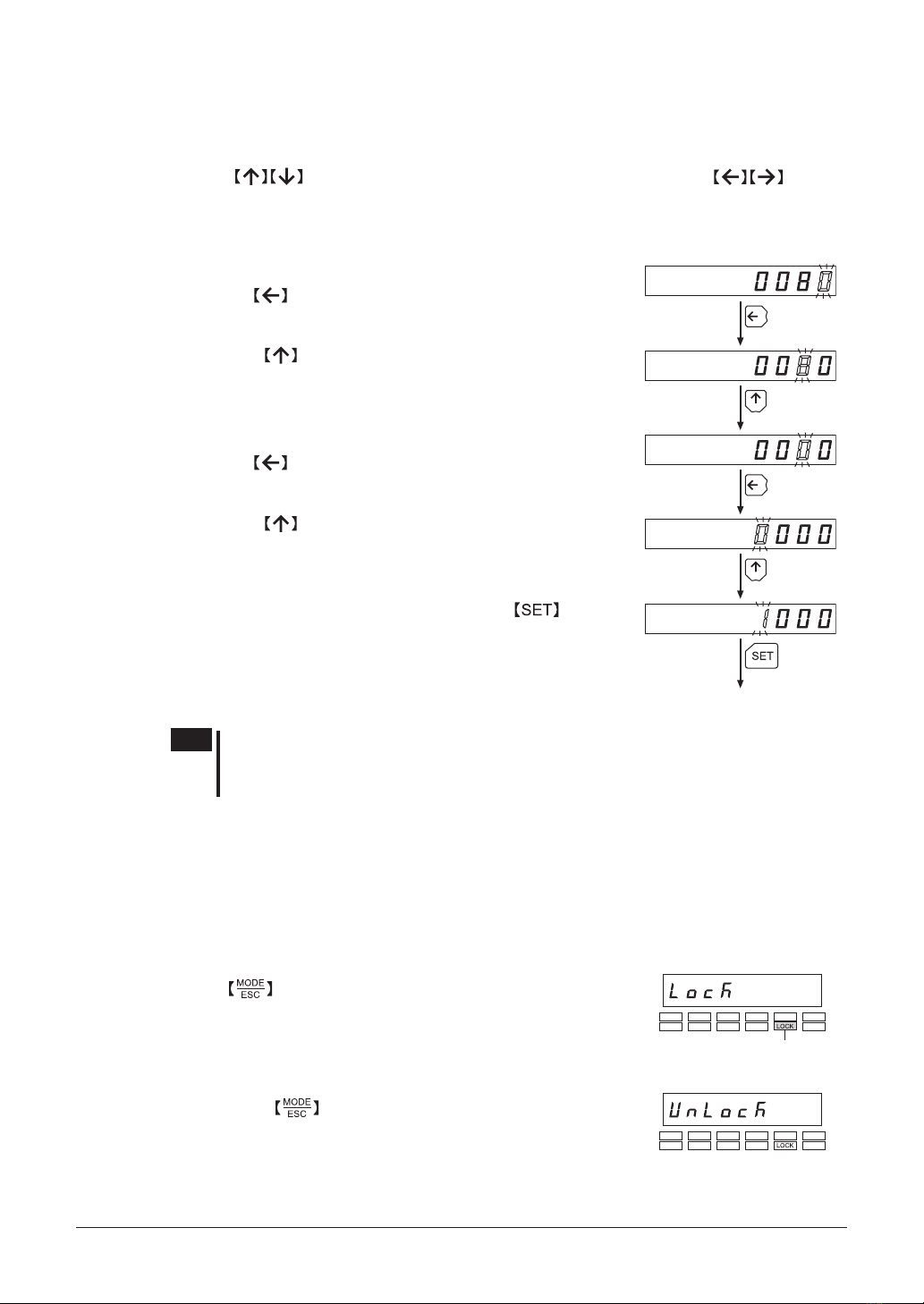

3.6 Basic operations of the OPX-2A .............. 7

3.7 Edit lock function ..................................... 8

3.8 Rewriting the driver’s non-volatile

memory .................................................... 9

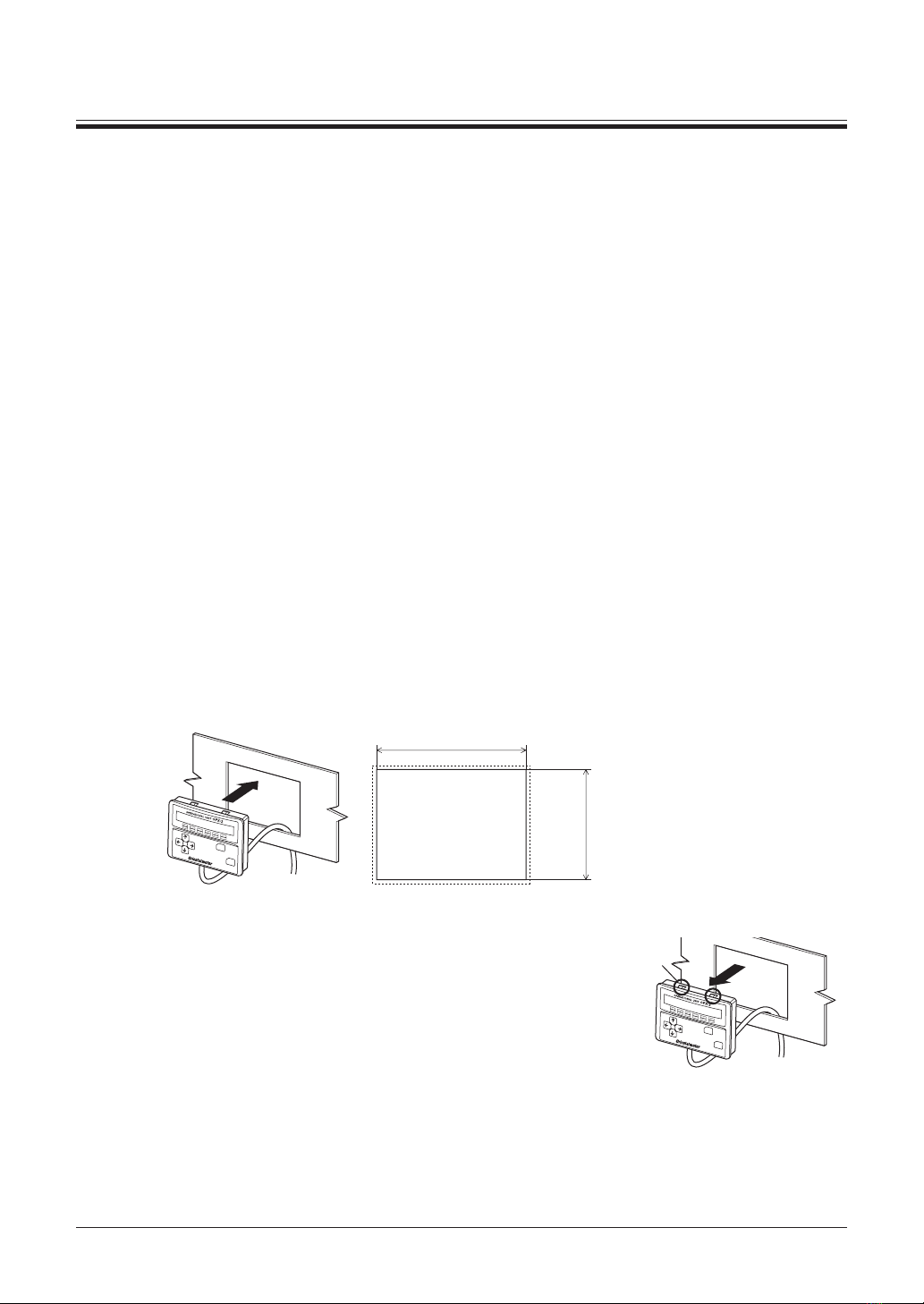

4 Installation and connection of the

OPX-2A ............................................. 10

4.1 Location for installation .......................... 10

4.2 Installation method ................................ 10

4.3 Connecting to the driver .........................11

4.4 Error display on OPX-2A screen ............11

5 Screen transitions ............................. 12

6 Monitor mode .................................... 16

6.1 Overview of the monitor mode ............... 16

6.2 Monitored items ..................................... 16

7 Data mode ......................................... 19

7.1 Setting items .......................................... 19

7.2 Initializing operation data ....................... 19

8 Parameter mode ............................... 20

8.1 Parameter ID ......................................... 20

8.2 Setting example ..................................... 30

9 Test mode .......................................... 32

9.1 Overview of the test mode ..................... 32

9.2 I/O test ................................................... 32

9.3 JOG operation ....................................... 33

10 Copy mode ........................................ 34

10.1 Overview of the copy mode ................... 34

10.2 Downloading to the driver ...................... 35

10.3 Uploading to the OPX-2A ...................... 35

10.4 Verifying data ......................................... 36

10.5 Initializing driver data ............................. 36

Table of contents