2

Operation

yDo not touch the motor output shaft or the load shaft during operation.

Doing so may result in injury.

yProvide an emergency stop device or emergency stop circuit external to

the equipment so that the entire equipment will operate safely in the event

of a system failure or malfunction. Failure to do so may result in injury.

yThe motor surface temperature may exceed 70 °C (158 °F)

even under normal operating conditions. If the operator is

allowed to approach the motor in operation, ax a warning

label shown in the gure on a conspicuous position. Failure to

do so may result in a skin burn(s).

Warning

label

yFor a DC power supply for electromagnetic brake, use a DC power supply

with reinforced insulation on its primary and secondary sides. Failure to do

so may result in electric shock.

Inspection and maintenance

yDo not touch the terminals while conducting the insulation resistance

measurement or the dielectric strength test. Doing so may result in electric

shock.

Precautions for use

This section covers restrictions and requirements the user should consider

when using the product.

•Be sure to use our cable to connect the motor and the driver.

Check the cable models on p.7.

•When conducting the insulation resistance measurement or

the dielectric strength test, be sure to separate the connection

between the motor and the driver.

Conducting the insulation resistance measurement or the dielectric strength

test with the motor and the driver connected may result in damage to the

product.

•Do not apply a radial load and axial load in excess of the

specied permissible limit.

Continuing to operate the motor under an excessive radial load or axial load

may damage the bearings (ball bearings) of the motor. Be sure to operate the

motor below the specied permissible limits of the radial load and axial load.

Refer to p.6 for details.

•Use the motor in a condition where the motor surface

temperature does not exceed 100 °C (212 °F).

The motor does not have a function to protect from overheating. The surface

temperature on the motor case may exceed 100 °C (212 °F) depending on

operating conditions such as ambient temperature, operating speed, duty

cycle, and others. To prevent the bearings (ball bearings) of the motor from

reaching its usable life quickly, use the motor in a condition where the surface

temperature does not exceed 100 °C (212 °F).

Also, use in a condition where the surface temperature of the gearhead does

not exceed 70 °C (158 °F) in order to prevent deterioration of grease and parts

in the gearhead.

If the motor is to be operated continuously, install the motor in a location

where heat dissipation capacity equivalent to a level achieved with a heat

sink [made of aluminum, 250×250×6 mm (9.84×9.84×0.24 in.)] is ensured.

•Holding torque at standstill

The motor holding torque is reduced by the current cutback function of the

driver at motor standstill. When selecting a motor, check the holding torque

at motor standstill in the specications on the catalog.

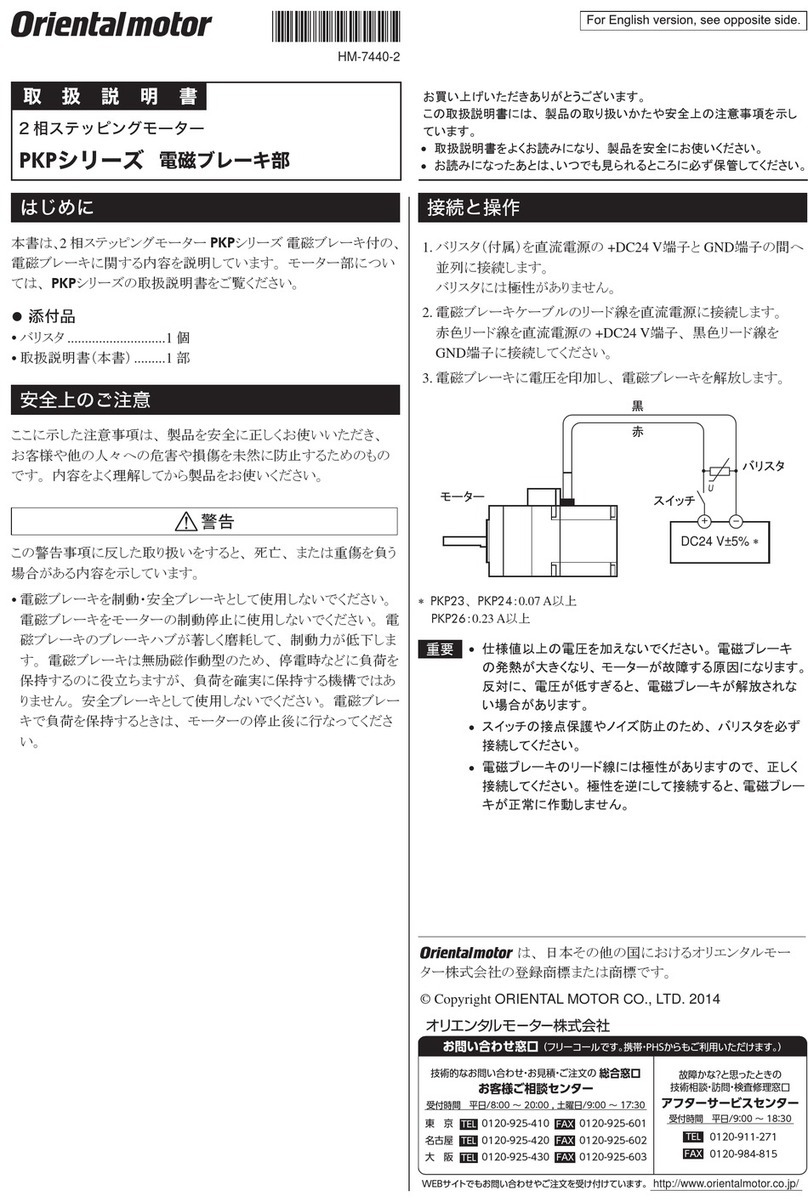

•Do not use the electromagnetic brake for braking or as a safety

brake.

Do not use the electromagnetic brake as a means to brake and stop the

motor. The brake hub of the electromagnetic brake will wear signicantly and

the braking force will drop.

Since the power o activated type electromagnetic brake is equipped, it

helps maintain the position of the load when the power is cut o, but this

brake is not a mechanism that holds the load in place securely. Do not use the

electromagnetic brake as a safety brake. To use the electromagnetic brake to

hold the load in place, do so after the motor has stopped.

•Noise elimination measures

Refer to the USER MANUAL for the noise elimination measures.

•Peak torque

Always operate the motor under a load not exceeding the peak torque. If the

load exceeds the peak torque, the gear will be damaged.

•Rotation direction of the output shaft

The rotation direction of the output shaft is set with the “Motor rotation

direction”parameter. The rotation direction of the output shaft with respect

to the setting of the “Motor rotation direction”parameter is shown below.

Setting of parameter Viewed from front face Viewed from rear face

Positive = CW

or

Positive direction = CW

Positive = CCW

or

Positive direction = CCW CW

•Do not perform push-motion operation

Doing so may result in damage to the motor or gearhead.

•Grease measures

On rare occasions, a small amount of grease may ooze out from the motor.

If there is concern over possible environmental damage resulting from

the leakage of grease, check for grease stains during regular inspections.

Alternatively, install an oil pan or other device to prevent leakage from

causing further damage. Oil leakage may lead to problems in the customer’s

equipment or products.

Notes when the connection cable is used

Note the following points when our cable is used.

The connector cover is not shown in the gure.

•When inserting the connector

Hold the connector main body, and

insert it in straight securely.

Inserting the connector in an

inclined state may result in damage

to terminals or a connection failure.

•When pulling out the connector

Pull out the connector in straight while releasing the lock part of the

connector. Pulling out the connector with holding the cable may result in

damage to the connector.

•Bending radius of cable

Use the cable in a state where the

bending radius of the cable is more than

six times of the cable diameter.

Do not bend the lead wires part or x

it with a clamp. Doing so may cause

damage to the connector.

More than 6 times

of cable diameter

lead wires part