2

Caution

Handling the product without observing the instructions that accompany a

“Caution” symbol may result in injury or property damage.

General

• Do not use the motor beyond its specifications, or electric shock, injury or

damage to equipment may result.

• Do not touch the motor during operation or immediately after stopping. The

surface is hot and may cause a skin burn(s).

Transportation

• Do not hold the motor output shaft or motor cable. This may cause injury.

Installation

• Provide a cover over the rotating parts (output shaft) of the motor to prevent

injury.

Operation

• Do not touch the rotating parts (output shaft) of the motor during operation.

This may cause injury.

• Provide an emergency stop device or emergency stop circuit external to the

equipment so that the entire equipment will operate safely in the event of a

system failure or malfunction. Failure to do so may result in injury.

• The motor’s surface temperature may exceed 70 °C (158 °F),

even under normal operating conditions. If a motor is

accessible during operation, post a warning label shown in the

figure in a conspicuous position to prevent the risk of skin

burn(s).

Warning

label

• For the power supply input to the electromagnetic brake, use a DC power

supply with reinforced insulation on the primary side.

Maintenance and inspection

• To prevent the risk of electric shock, do not touch the terminals while

measuring the insulation resistance or conducting a voltage-resistance test.

Disposal

• To dispose of the motor, disassemble it into parts and components as much

as possible and dispose of individual parts/components as industrial waste.

Precautions for use

• Conduct the insulation resistance measurement or withstand voltage

test separately on the motor and the driver.

Conducting the insulation resistance measurement or withstand voltage test with

the motor and driver connected may result in injury or damage to equipment.

• Do not apply an overhung load and thrust load in excess of the

specified permissible limit.

Operating the motor under an excessive overhung load and thrust load may

damage the motor bearings (ball bearings). Be sure to operate the motor within

the specified permissible limit of overhung load and thrust load.

• Do not use the electromagnetic brake to reduce speed or as a safety

brake.

The electromagnetic brake is of non-excitation type. Although it helps maintain

the position of the load in the event of power outage, etc., this brake cannot

securely hold the load in place. Always stop the motor first, and then use the

electromagnetic brake to maintain the position of the load.

• Preventing electrical noise

See USER’S MANUAL for measures with regard to noise.

• Do not apply impact to the encoder.

If the encoder receives strong impact, the encoder may be damaged or the

motor may malfunction.

• About grease of geared motor

On rare occasions, a small amount of grease may ooze out from the geared

motor. If there is concern over possible environmental damage resulting from

the leakage of grease, check for grease stains during regular inspections.

Alternatively, install an oil pan or other device to prevent leakage from causing

further damage. Oil leakage may lead to problems in the customer’s equipment

or products.

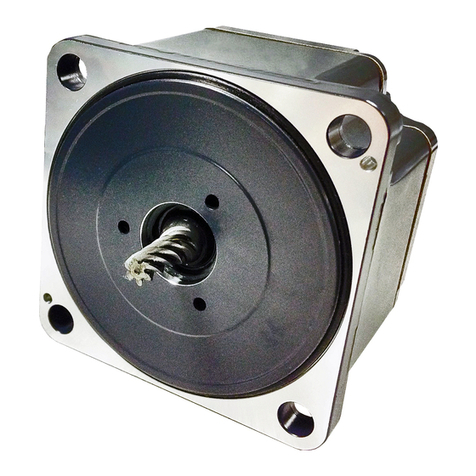

Installation

Location for installation

The motor is designed and manufactured for installation in equipment. Install it

in a well-ventilated location that provides easy access for inspection. The

location must also satisfy the following conditions:

• Inside an enclosure that is installed indoors (provide vent holes)

• Operating ambient temperature 0 to +40 °C (+32 to +104 °F) (non-freezing)

• Operating ambient humidity 85% or less (non-condensing)

• Area that is free of explosive atmosphere or toxic gas (such as sulfuric gas) or

liquid

• Area not exposed to direct sun

• Area not subject to splashing oil (oil droplets) or other liquids

• Area free of excessive salt

• Area not subject to continuous vibration or excessive shocks

• Area free of excessive electromagnetic noise (from welders, power machinery,

etc.)

• Area free of radioactive materials, magnetic fields or vacuum

• 1000 m (3300 ft.) or lower above sea level

Installation direction

The motor can be installed in any direction. There is an exception, however, in

humid places, areas subject to mist and other environments where water

accumulates easily. In such environments, the motor should be installed in the

direction whereby the motor cable extends downward.

Installation method

To allow for prevent vibration, install the motor on a metal surface of sufficient

strength. Install the motor in a location where heat dissipation capacity

equivalent to a level achieved with a heat sink (made of aluminum) is ensured.

Refer to the table below for the heak sink.

Motor model Heat sink size [mm (in.)]

NXM45, NXM410, NXM620, NXM65-PS,

NXM610-PS, NXM920-PS, NXM810-J,

NXM820-J

250×250×6 (9.84×9.84×0.24)

NXM640, NXM940-PS, NXM1040-J300×300×10 (11.81×11.81×0.39)

NXM975, NXM1075-J350×350×10 (13.78×13.78×0.39)

∗ within the model name represents the gear ratio.

●Motor frame size: 42 mm (1.65 in.)

Secure at the two mounting holes according to the installation method

appropriate for your specific method of use.

Installation method A

Pilot holder

Installation method B

Pilot holder

Motor type Frame size

[mm (in.)]

Bolt

size

Tightening

torque

[N·m (oz-in)]

Effective

depth of bolt

[mm (in.)]

Installation

method

6 (0.24) A

Standard 42 (1.65) M3 1 (142) −B

●Motor frame size: 60 to 104 mm (2.36 to 4.09 in.)

Secure at the four mounting holes according to the installation method

appropriate for your specific method of use.

Installation method C

Pilot holder

Installation method D

Motor type Frame size

[mm (in.)]

Bolt

size

Tightening

torque

[N·m (oz-in)]

Effective

depth of bolt

[mm (in.)]

Installation

method

60 (2.36) M4 2 (280)

Standard 85 (3.35) M6 3 (420) −D

60 (2.36) M5 2.5 (350) 10 (0.39)

PS geared 90 (3.54) M8 4 (560) 15 (0.59) C

80 (3.15) M6 9 (1270)

PJ geared 104 (4.09) M8 15 (2100) −D