■

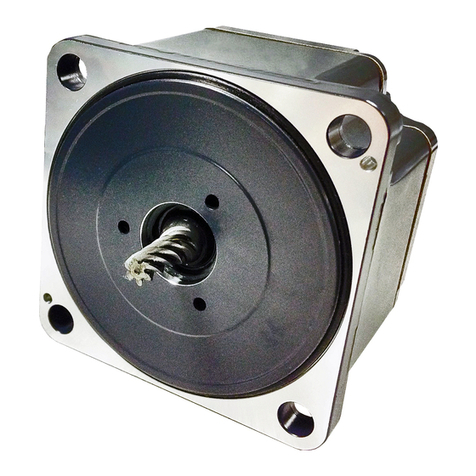

Method of installation

Install the motor on a smooth metallic plate offering a high resistance to vibration and excellent

heat-conductive properties.

●

Round shaft type

Using the four installation holes (or tapped holes) located on the motor's installation surfaces,

secure the motor with four bolts (not provided).

The motor's mounting pilot on the motor-installation hole should be inserted into the mounting-

pilot holder, which is countersunk or drilled through.

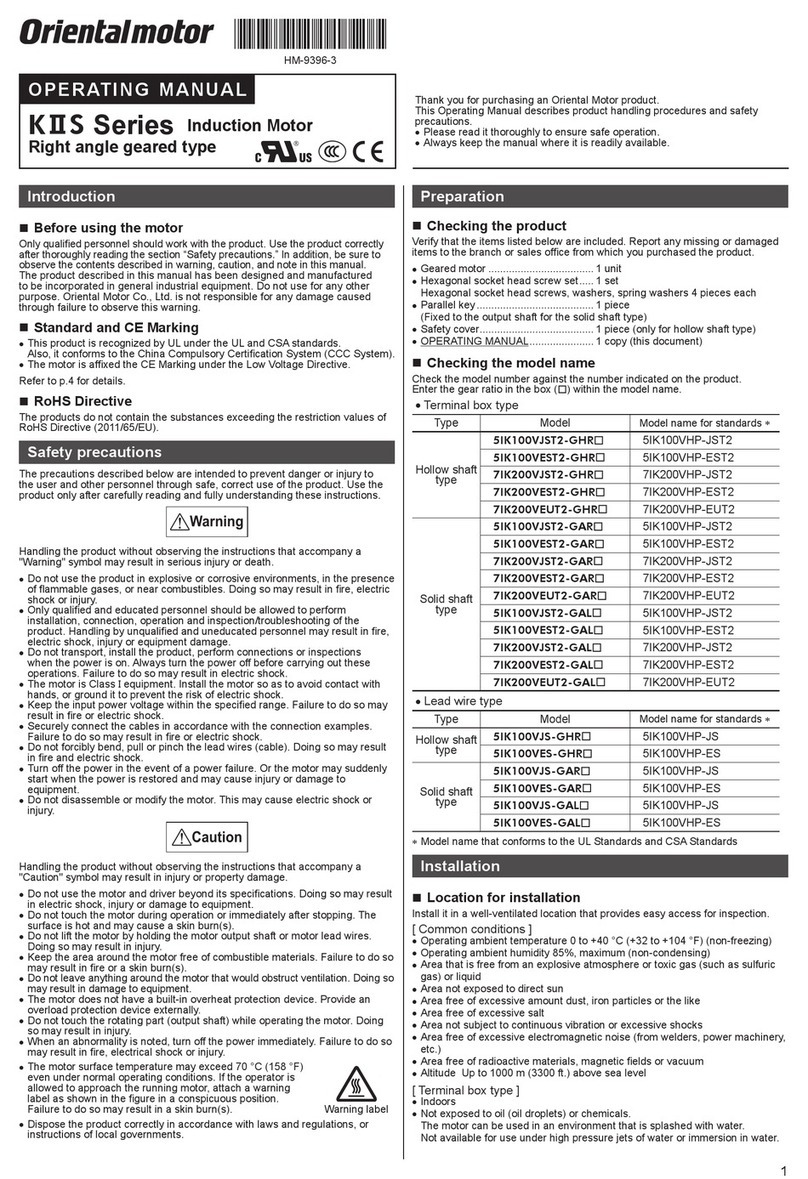

Low-Speed Synchronous Motor

SMK Series

OPERATING MANUAL

Thank you for purchasing an ORIENTAL MOTOR product.

This Operating Manual describes product handling procedures and safety precautions.

●

Please read it thoroughly to ensure safe operation.

●

Always keep the manual where it is readily accessible.

Only qualified personnel should work with the product.

This product is designed for incorporation in general industrial machinery, and must not be used

for another purpose. ORIENTAL MOTOR Co., Ltd. is not responsible for any damage caused

through failure to observe this warning.

This product is UL-recognized (impedance-protected), and has made self-declaration of the

CE marking (the Low-Voltage Directive). ( This does not apply to the SMK014A-A ,

SMK014A-B, SMK014MA-A, SMK014MA-B, SMK014K-A, SMK014K-B,

SMK014K-AA , SMK0A- A and SMK0A- B.)

■

Installation conditions

Overvoltage category

II

, Pollution degree 2, Class

I

equipment

■

Hazardous substances

RoHS (Directive 2002/ 95/ EC 27Jan.2003) compliant

Introduction

The precautions described below are intended to ensure the safe and correct use of the prod-

uct, and to prevent the customer or others from exposure to the risk of injury.

Read the body of the text based on a sufficient understanding of its importance.

Safety precautions

Warning

●

SMK0 type

●

SMK2, SMK5 type

Failure to observe the warnings contained herein may result in a situation leading to serious

injury or death.

●

Do not use the product in explosive or corrosive environments, in the presence of flammable

gases, locations subjected to splashing water, or near combustibles. Doing so may result in

fire, electric shock or injury.

●

Qualified personnel are required for the installation, connection, operation and inspection of

this product. Failure to do so may result in fire, electric shock or injury.

●

Be sure to turn off the power before installing, connecting or inspecting this product. Failure

to do so may result in electric shock.

●

Install the motor in the enclosure to avoid contact with the hands, or provide sufficient ground-

ing. Failure to do so may result in electric shock or injury.

●

Connect this product securely and accurately, according to the connection diagrams. Failure

to do so may result in fire or electric shock.

●

Be sure to insulate the connection terminals of the capacitor and external resistor. Failure to

do so may result in electric shock.

●

Do not forcibly bend, pull or pinch the motor cable. Doing so may result in fire or electric

shock.

●

In case of power failure, be sure to turn off the power. Failure to do so may cause the motor

to start suddenly when the power is restored, and could result in injury or damage to the

equipment.

●

If this product is used in an elevator application, be sure to provide a measure for the posi-

tion retention of moving parts. The motor loses its retentiveness when the power is turned off.

Failure to provide such a measure may cause the moving parts to fall off, resulting in injury

or damage to the equipment.

●

Do not touch the connection terminals of the motor or capacitor immediately after the power

is turned off (for a period of 30 seconds). The residual voltage may cause electric shock.

●

Do not disassemble or modify the motor. Doing so may result in electric shock, injury or dam-

age to the equipment.

■

Installation site

The motor is designed and manufactured for incorporation in machinery and equipment. Install

it at the site in consideration of the following to ensure effective ventilation and easy inspec-

tion:

◆

In indoor enclosure (where a ventilation port must be provided)

◆

Ambient temperature:

-

10°C~ +40°C(non-freezing)

[+14°F~ +104°F ]

◆

Ambient humidity: 85% or less (non-condensing)

◆

Not in an explosive atmosphere in the presence of hazardous gas (sulfide gas) or liquid

◆

Not at a site exposed to sunlight

◆

Not at a site exposed to dust or metallic chips and particulate matter

◆

Not subject to splashing water (rainstorm and otherwise), oils or other liquids

◆

Not at a site containing excessive salt

◆

Not subjected to continuous vibration or excessive shock

◆

Not exposed to electromagnetic noise (welders and power equipment)

◆

Not in the presence of radiation, magnetic fields or a vacuum environment

◆

At an elevation not exceeding 1,000 meters (3,300 ft.)

Installation

Caution

Failure to observe the following precautions may result in injury or property damage.

●

Do not use the motor beyond the specified values. Doing so may result in electric shock,

injury or damage to the equipment.

●

Do not hold the motor shaft or motor cable. Doing so may result in injury.

●

Provide an emergency-stop device or emergency-stop circuit external to the equipment so that

the entire equipment will operate safely in the event of a system failure or malfunction. Failure

to do so may result in injury.

●

Be sure to secure the motor onto the metal plate. Failure to do so may result in injury or dam-

age to the equipment.

●

Be sure to cover the rotating portion (motor shaft) of the motor. Failure to do so may result in

injury.

●

Immediately when trouble has occurred, stop running and turn off the power. Failure to do so

may result in fire, electric shock or injury.

●

Do not touch the motor or external resistor during operation or immediately after the equip-

ment is stopped, since the surfaces of the motor and external resistor will be extremely hot.

Failure to do so may result in a burn.

●

The surface temperature of the motor may exceed 70°C (158°F), even during normal oper-

ation. Be sure to attach a warning label, as shown in the figure, in a clearly visible location if

it is possible for the operator to access the motor during operation.

Failure to do so may result in a burn.

●

To dispose of the motor, disassemble it into parts and components as much as possible and

dispose of individual parts/components as industrial waste.

400Ω

1500Ω

400Ω

400Ω

2000Ω

-

-

-

-

30W

30W

30W

30W

30W

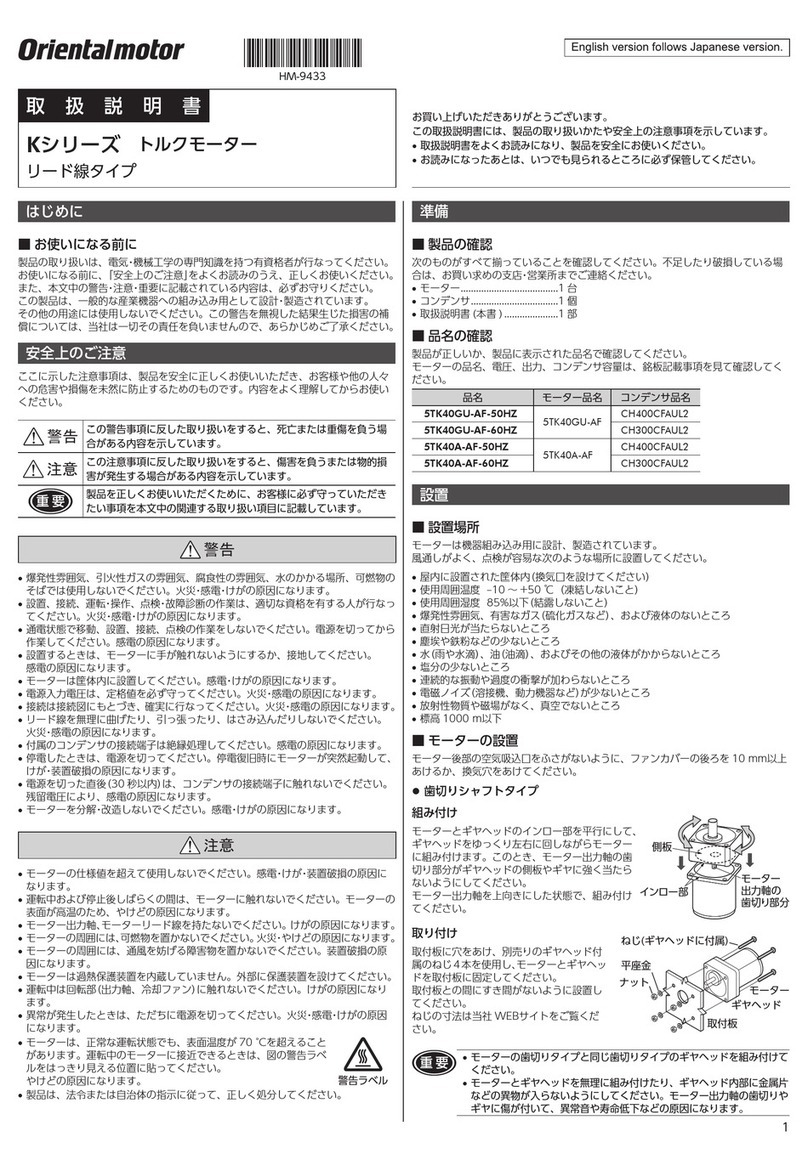

Model Capacitor External resistor

SMK014A-A, SMK014A-B

SMK014MA-A, SMK014MA-B

SMK014K-A, SMK014K-B

SMK014K-AA

SMK0A- A

∗1

, SMK0A- B

∗1

SMK237A-A, SMK237A-B

SMK216A-GN, SMK216A-GNB

SMK5100A-A, SMK5100A-B

SMK5100A-AA, SMK5100A-BA

SMK5100C-A, SMK5100C-B

SMK5160A-A, SMK5160A-B

SMK5160A-AA, SMK5160A-BA

SMK550A-GN, SMK550A-GNB, SMK550A-GNBA

SMK550C-GN, SMK550C-GNB

0.6

µ

F

∗2

12

µ

F

0.6

µ

F

∗2

1.2

µ

F

∗2

2.5

µ

F

∗2

0.6

µ

F

∗2

2.5

µ

F

∗2

0.6

µ

F

∗2

0.35

µ

F

∗1

Mounting screws (4 pieces) are provided.

∗2

A capacitor cap is provided.

Open the package and verify that the following items are present. If there is any shortage or

damage, contact the sales office from which you purchased the product.

Product confirmation

◆

Conduct the insulation resistance measurement or withstand voltage test separately on

the motor and the driver.

Failure to do so may result in equipment damage.

◆

Do not give any constraint to the motor shaft.

If the motor shaft is constrained with a load torque exceeding the motor torque, the motor can-

not be started and a vibrating condition will occur, resulting in a significant decrease in motor

life. Be sure to use a load torque that is less than the motor torque.

Precautions for use

HM-4006-8

A box ( ) of the model is filled with a number to represent the gear ratio.

◆

About grease of the geared motor

On rare occasions, a small amount of grease may ooze out from the geared motor. If there

is concern over possible environmental damage resulting from the leakage of grease, check

for grease stains during regular inspections. Alternatively, install an oil pan or other device

to prevent leakage from causing further damage. Oil leakage may lead to problems in the cus-

tomer’s equipment or products.

◆

Allowable torque

Operate the motor by making sure the sum of the acceleration/deceleration torque at the

starting/stopping of the motor and the load (friction) torque doesn’t exceed the allowable

torque. Operating the motor in excess of the allowable torque may result in a damaged gear.