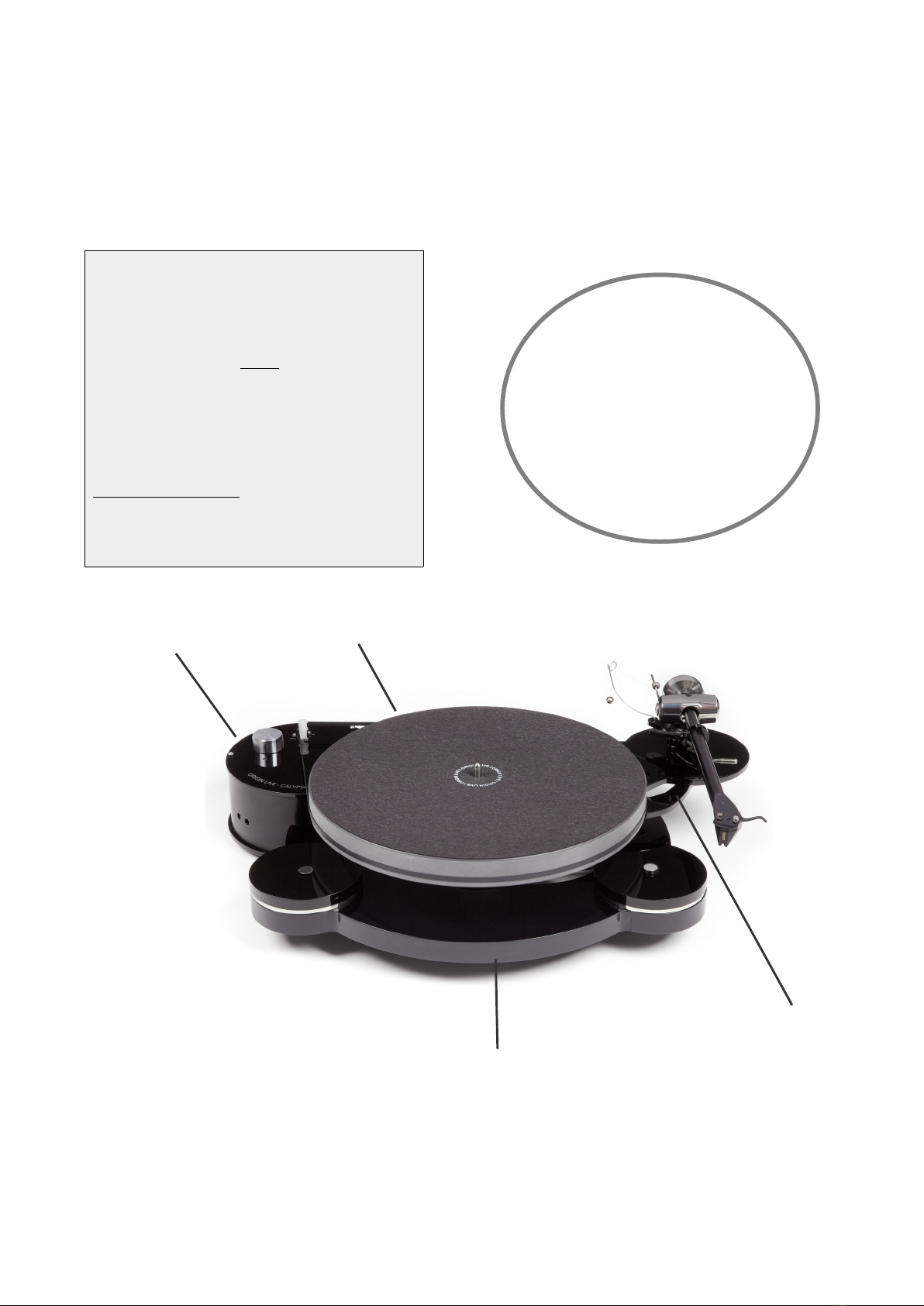

Control nob operation

The motor is “off” when the speed control knob on the

pod is turned fully anti-clockwise and the indent on the

knob aligns to the reference point.

Turn the knob one click clockwise to turn the motor on

at 33.3 rpm - The second click clockwise is 45rpm

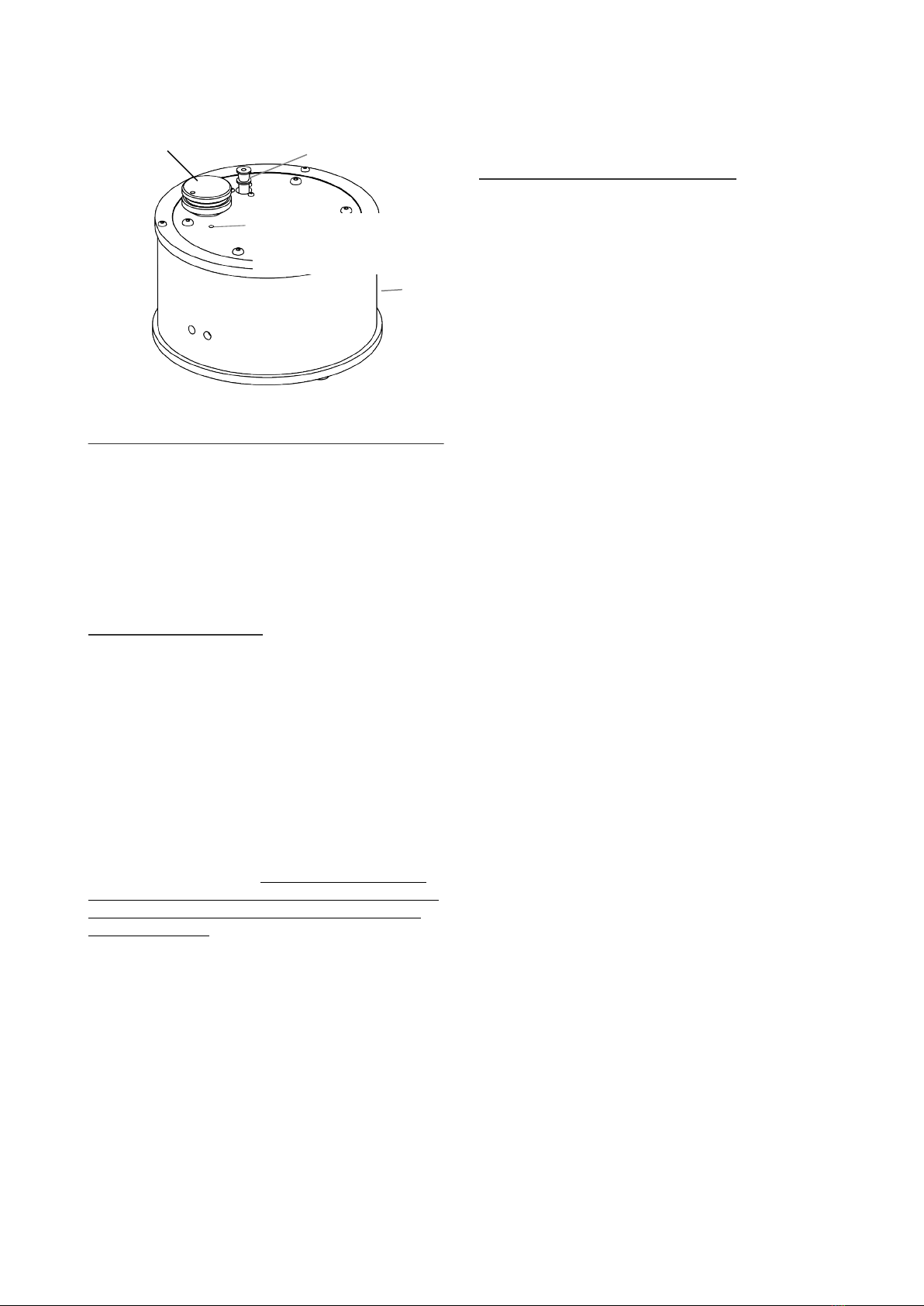

Operating the strobe

You can check the speed of your deck by placing the

strobe disc on the record to be played. The strobe rings

are labelled on the centre of the disc for speed and mains

frequency.

Use correct lighting

The strobe effect shows best in fluorescent light,

although an ordinary bulb held about 2 feet from the

strobe disc will also work fine. The bulb flickers at 50

Hz in the EEC and 60 Hz in the USA.

You can purchase bayonet fitting fluorescent or halogen

bulbs to fit normal lamps. Try to shut out daylight when

carrying out speed reading. Also be aware that energy

saving lighting with switch mode high frequency power

supplies or certain energy saving bulbs will not work

with the strobe disc.

Reading the strobe

As you play the record. watch the relevant ring on the

strobe disc. Read the speed as described in ne t sub-

heading until marks on the ring concerned appear

stationary. It sometimes helps to stare the strobe but

focus your eyes on infinity.

Alternative methods

There are other strobes which are easier to read such as

the KAB strobe which can be found on our web site

under vinyl measurement accessories.

There is also a phone app that you can download for

Android or IOS. You simply then place the phone on the

platter and it reads the speed (but not very reliably).

Best results are achieved with the phone close to the

centre of the platter and ideally it should be supported

over the centre spindle of the platter.

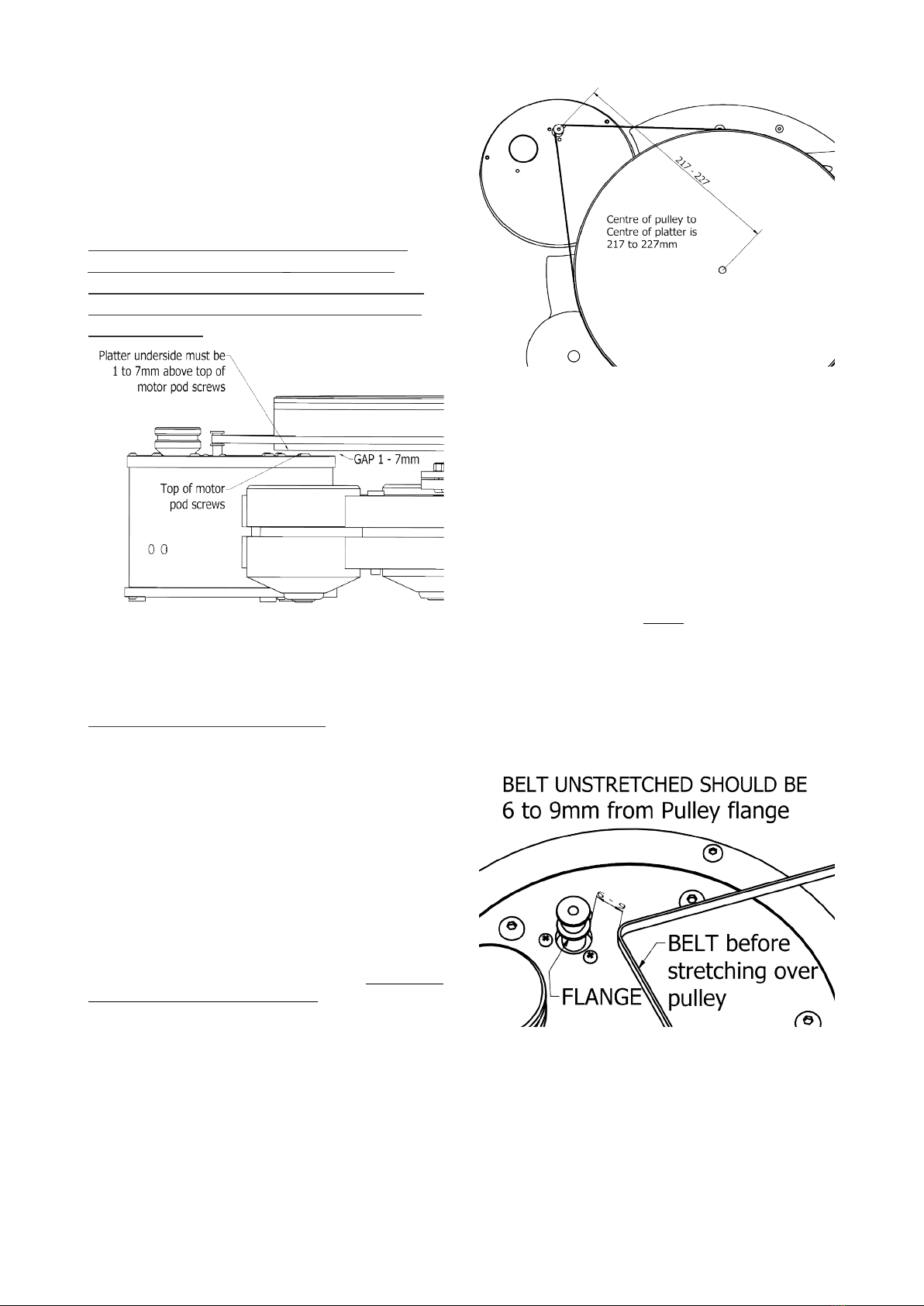

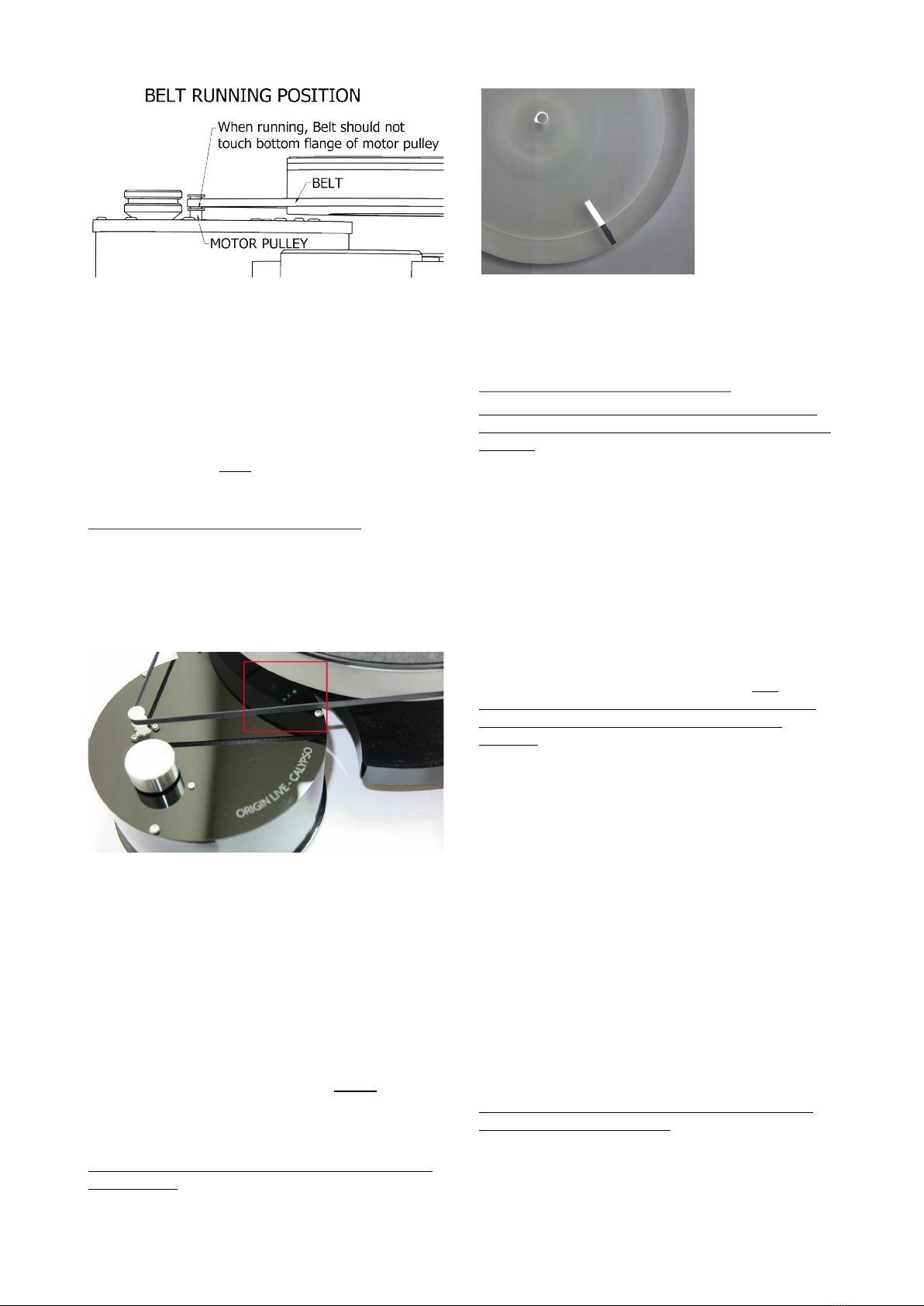

Notes on Belt & Motor running

Motor Tilt

Check that the belt rides clear of the flanges – nearly

touching is OK but if the belt sinks down to touch the

flange you need to either increase belt tension slightly or

adjust the tilt of the motor by turning the small cross-

head motor mounting screw positioned nearest the

platter.

Motor Noise

DC motors are often slightly noisy initially and never

completely silent in comparison to a/c motors. This may

be due in part to the high conductivity precious metal

brushes. These produce much lower levels of vibration

and hence better performance.

Like most turntable manufacturers we recommend you

leave the turntable running between changing records as

this reduces belt wear due to constant stopping and

starting.

Why measurements can be misleading

The figures on speed accuracy of the deck are well ahead

of industry standards however it's worth mentioning that

the Fleikhart measurement system is now well reported

on the web to be inaccurate due to off-centre discs and

poorly recorded tone. It has currently been withdrawn

from production.

Similarly Mobile phone apps are only a rough guide.

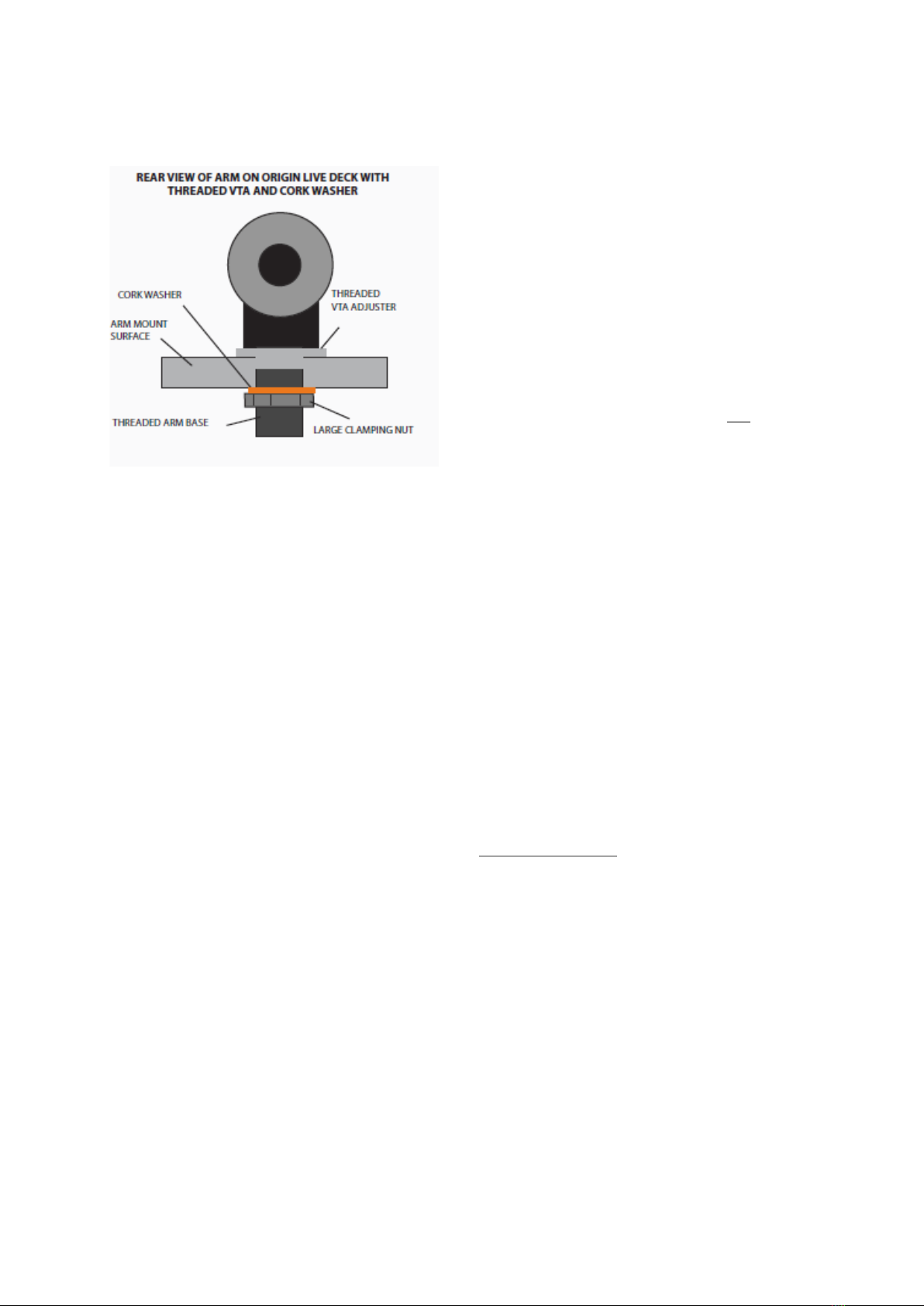

Fit the tonearm

Mounting Origin Live arms

All newer Origin Live arms have built in VTA

adjustment and can be fitted directly to the arm board as

illustrated below.

If you have an older Origin Live or Rega tone-arm which

has a threaded base but no vta adjustment, you can fit a

threaded VTA adjuster. The adjuster must be threaded

onto the base of the arm first and oriented such that the

flange is uppermost.

Insert your arm through the hole in the arm board.

Ne t fit the cork washer followed by the large clamping

nut as shown in the diagram on this page.

Lastly fit the tone-arm cables through the cable clip on

the underside of the deck. This improves performance

slightly and safeguards the cables from stressing their

joint at the arm base in the event of being “tugged”. The

cables should not be tight but form a gentle loop.

If clamping the cable is undesirable you can omit this

step.