Page 7

-The motor and main bearing will take at least 4 days to fully

run in and sound it’s best. For this reason it is best to do a final

speed check at the end of this period.

The speed stability of your deck will be excellent once

everything has settled down in a listening session.

When checking speed - Be aware that the speed is subject

to temperature variation. This is due to oil thickening as the

temperture drops. 1 degree centigrade drop in temperature

results in a 0.1% drop in speed ( a 5 degree drop will be 0.5%

slow). 0.5% speed drift is barely noticable to the average

listner so this is not significant. Rega decks used to run 1% fast

all the time to put things in perspective.

The ear is less tolerant to music running slow than it is to

fast. For this reason it is worth setting the deck to run very

slightly fast at your average room temperature. Most houses

are centraly heated and maintain the temperature such that

significant variations simply do not occure.

Note that the main bearing and oil can take 2 hours to reach

operating temperature if the deck is left in a cold room. The

air in the room may warm up quickly but the metal in the

turntable will take a lot longer. For this reason it is not worth

constantly changing speed settings for absolute accuracy.

It is worth explaining that absolute speed accuracy is easy

to achieve at the expense of sound quality. The ac motors,

common to most decks are not prone to speed drift - however

they do inject a great deal of vibration. This, sadly is never

measured in technical reviews or people would be a lot wiser.

The subjective effect of vibration is highly detrimental to

sound quality when compared to fractional speed drift. For

this reason we prefer to offer superior sound quality rather

than the flawed illusion of technical perfection.

Further to this it is worth adding that we have experimented

with the latest highly sophisticated dc speed controls (£1000

plus trade cost) and found that although they hold speed with

unerring accuracy, the sound and dynamics of the music are

degraded to such a degree that a little speed drift is far more

preferable.

FINAL SETUP OF TONEARM

Refer to your tonearm instructions. Use the following, only as

a rough guide on aspects relevent to the turntable.

VTA (vertical tracking adjustment)

To allow the cartridge needle to track at the correct angle it is

important that the base of the arm is at the correct height in

relation to the platter - this can be set by rotating the chrome

threaded VTA adjuster supplied with the deck for Origin Live

and Rega derived arms. One complete turn of the adjuster

clockwise raises the arm 1mm. For Origin Live arms that

have an integral vta adjuster the threaded vta adjuster is best

ommitted.

Fit the arm cable clip

Pass the arm cable through the cable clip and fasten in position

with the nut & bolt supplied. Leave a slight droop on the

cable so that it isn’t “tight”. The clip fastens to the underside

of the plinth using the hole near the rear foot. This is helpful

to “earth” vibration in the cable. The earth lead should be

connected to the earth of your pre-amplifier or amplifier. This

earth lead is best separated slightly from the arm signal leads so

do not wind it around them for best performance.

Note - The linear flow 2 cable is thicker than most, use the

larger cable clip to cope with this - if the cable is problamatic

to bend round the confines of your particular set up, then you

will not lose a great deal of performance by simply not using

the arm clip.

UPGRADES

It is possible to upgrade the turntable

Further upgrades would be

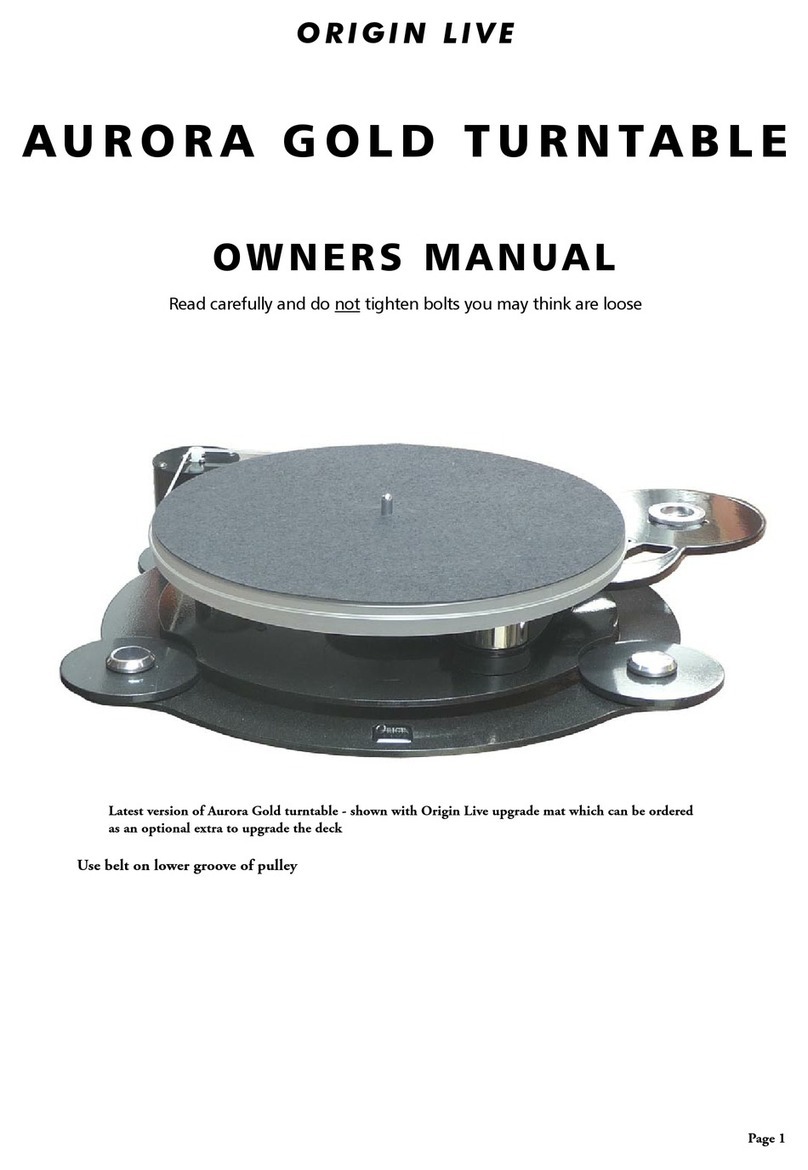

Origin Live upgrade platter mat for Aurora only

Upgrade Transformer - (Sovereign includes this as

standard)

MAINTENANCE OF DECK

It aids performance to clean all the running surfaces every 3

months or so with mentholated or surgical spirit but do not

use this on a flat belt.

Flat belts benefit from a 6 monthly application of any rubber

care product - typicaly found in car accessory stores.

To clean the deck, use a damp soft lint free cloth and wipe

gently – if you have grease marks etc then you can use a

general-purpose anti-smear, car window cleaner such as

Autoglym Fast glass, but only if necessary – wax furniture

polish is to be avoided . Do not spray directly on the turntable

as it may clog up the cartridge etc but rather spray onto a

soft polishing cloth and then use it on the turntable. Do not

use tissue paper or kitchen cleaning paper towels as paper is

abrasive and can put faint scratches in the polished surface.

If you do get minor abrasions on the surface then you can remove

them using a fine car paint abrasive polish such T-cut or Autoglym

paint renovator - this is especially usefull to remove stubborn grease

marks on the platter.

Keep the turntable packing box for secure future transport.

The deck is not prone to going out of tune - Check that the

sub-chassis damper is tensioned lightly onto the plate every 2

years or so as the damping can compress a little over time.

Depending on your use of the deck, the belt should ideally be

replaced every 2 years or so.

If you withdraw the main spindle you should put in a drop of

oil in the bearing, to compensate for any possible loss.

TROUBLESHOOTING

Omit reading this greyed out section unless you have a problem

SPEED VARIATION

If there is significant speed variation then possible causes are as follows.