3

TABLE OF CONTENTS

INTRODUCTION ..........................................................................................................................1

TABLE OF CONTENTS................................................................................................................3

SAFETY........................................................................................................................................5

SAFETY ALERT SYMBOL................................................................................................5

SIGNAL WORDS ..............................................................................................................5

SAFETY SIGNS................................................................................................................6

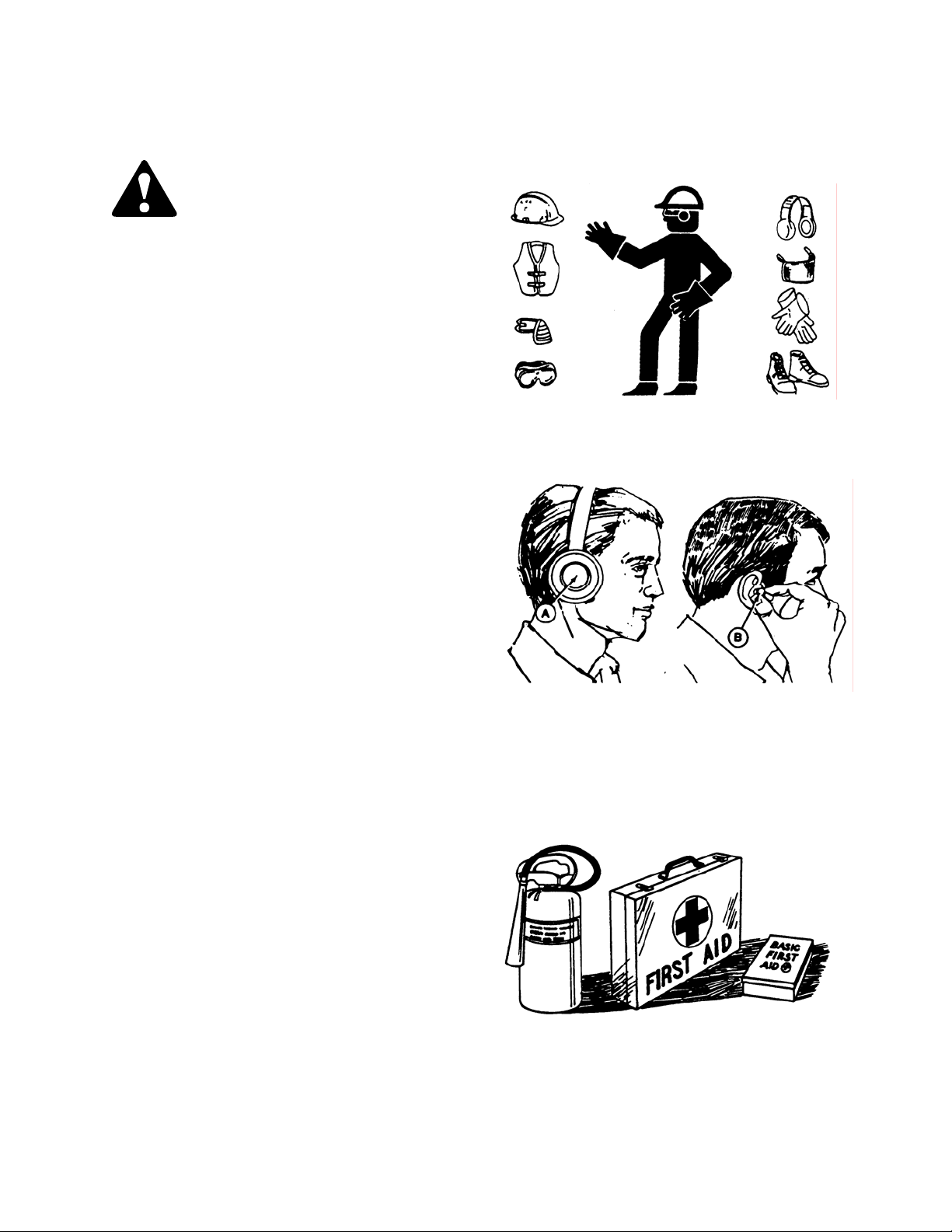

GENERAL SAFETY..........................................................................................................7

SPECIFICATIONS........................................................................................................................9

SERIAL NUMBER LOCATION ...................................................................................................10

ASSEMBLY INSTRUCTIONS.....................................................................................................11

LOADING ARM ASSEMBLY...........................................................................................13

OPERATION...............................................................................................................................17

YOUR RESPONSIBILITIES AS AN OWNER/OPERATOR ............................................17

TO THE NEW OPERATOR.............................................................................................18

HYDRAULIC/ELECTRICAL CONTROL..........................................................................18

ATTACHING BALE CARRIER TO TRACTOR................................................................19

ADJUSTING RIGHT WHEELS........................................................................................20

CABLE TENSION............................................................................................................20

CHAIN TENSION............................................................................................................20

CARRIER OPERATION..............................................................................................................22

CARRIER CONTROLS...................................................................................................22

PRE-START CHECKLIST...............................................................................................22

LOADING BALES............................................................................................................23

BALE PUSHER OPERATION.........................................................................................25

UNLOADING...................................................................................................................25

TRANSPORTING CARRIER...........................................................................................27

MAINTENANCE..........................................................................................................................28

FASTENERS...................................................................................................................28

HYDRAULIC SYSTEM....................................................................................................29

CHAIN/SPROCKETS......................................................................................................29

WHEELS/TIRES .............................................................................................................31

LUBRICATION................................................................................................................31

CABLE ............................................................................................................................32

STORAGE ..................................................................................................................................35

END OF SEASON...........................................................................................................35

START OF SEASON.......................................................................................................35

DURING THE SEASON..................................................................................................36

BALE STORAGE.............................................................................................................36