D-582-3-E

5

DELTA FLOWMETER

OVAL Corporation MADE IN JAPAN

MODEL

SER. No.

MAX. TEMP.

MAX. PRESS

DATE

TAG. No.

METER FACTOR

FACTORD PULSE

ANALOG F.S.

AMB. TEMP.

m3/h

L/P

/P

( )

Hz

°

C

°

C

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

RATEDMAX.FLOW

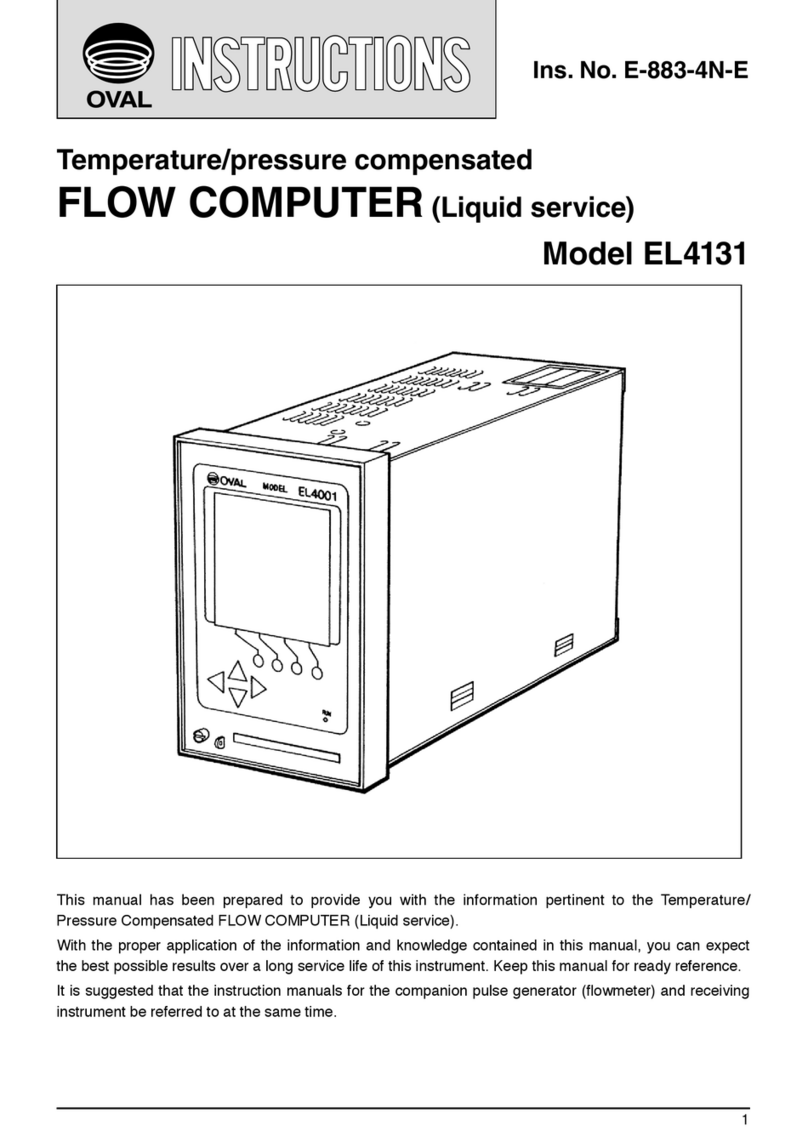

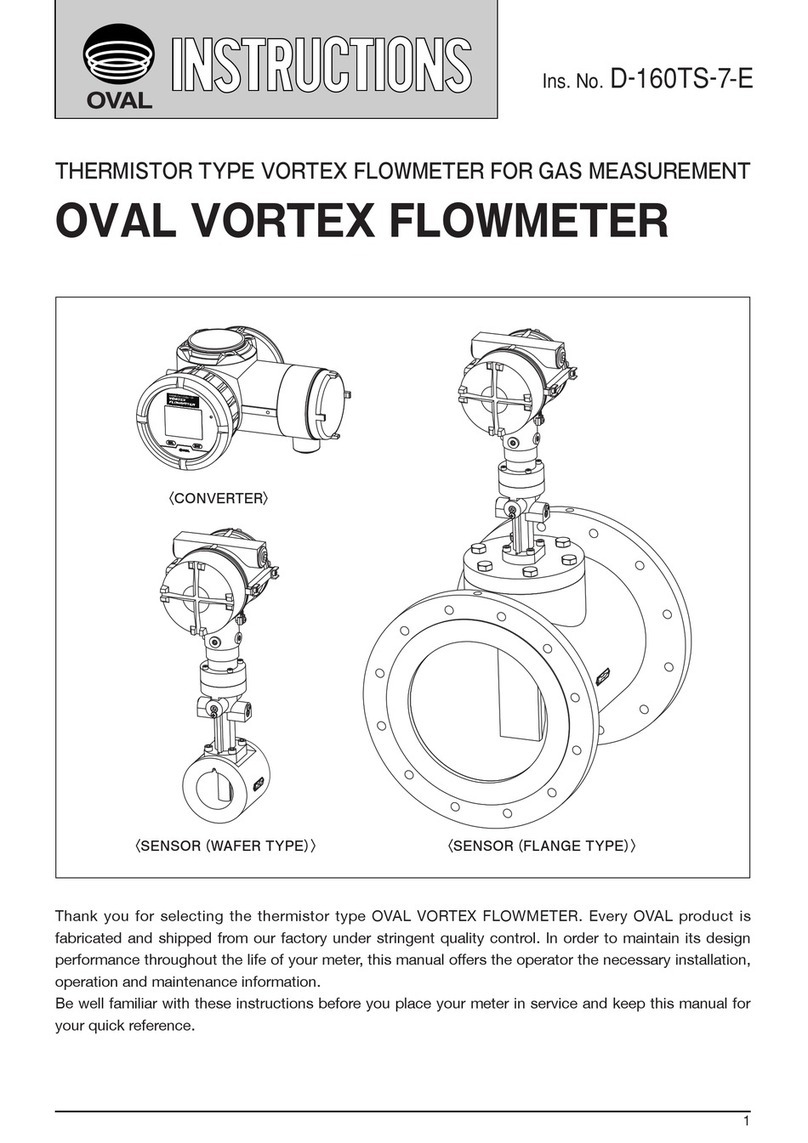

No. Item Description No. Item Description

①Model

―

⑧

Factored Pulse Unit

Not stated for analog output.

②Serial No.

―

⑨Analog F. S. Not stated for pulse output.

③Rated Max.

Flow

Max. flowrate stated in the

catalog in actual flowrate. ⑩Full Scale

Freq.

Full scale frequency established.

Not stated for pulse output.

④Max. Temp.

―

⑪Ambient Temp.

Max. allowable ambitent temp.

⑤Max. Pressure

―

⑫Tag No. Stated only where specified.

⑥Date

―

⑬Remarks Stated only where specified.

⑦Meter Factor

Unfactored pulse unit in pulse out.

1. BEFORE YOU BEGIN

1.1 Confirming the Specifications

(1) When received, the meter should be thoroughly inspected for indication of rough handling during

transit.

(2) Product code number and ratings are stated on the meter nameplate. Make sure that the ratings

shown conform to your particular specifications.

1.2 Transit Considerations

(1) It is desirable that the meter be transported to the installation site in the shipping container used for

transit from the factory.

(2) During transportation, exercise care to avoid impact shock and rainwater.

1.3 Storage Considerations

(1) The meter can best be stored in the shipping container used for transit from the factory.

(2) The place of storage should meet the following requirements:

●Free from rain and water

●Free from vibration and impact shocks

●With least temperature and humidity variation (around 25℃and 65% R.H.)

(3) A meter that has once been placed in service for any length of time should be washed clean to remove

residue metered material completely from its inner walls before storage. Waterproofing the cable

entrance should also

be taken into consideration.

CAUTION: Unauthorized modification will invalidate the specifications.

2. OPERATING CONDITIONS

(1)This flowmeter is developed, designed, and manufactured to be used as a flowmeter for general industrial

application. Therefore, when it is used for the application where its operation is directly related to the

safety of the relevant system or where the product is important in the facilities (such as process control

and custody transfer), you are requested to secure sufficient safety including safety design, redundancy

and duplication of the process, and implementation of periodic inspection. Do not use this flowmeter in the

case where its operation and performance is directly related to human life.

(2) If this flowmeter is used under appropriate conditions, it can demonstrate its stable performance without

aging degradation of accuracy. However, malfunction or failure may occur due to various factors. Thus,

considering the operating conditions, operating status, and importance in the process, you should study

the cycle of periodic maintenance and its items of your flowmeter. In order to secure long-term and safe

use, OVAL recommends the customer to verify the soundness of the flowmeter through periodic inspection

every two years. For the details of inspection, contact our sales agent or person in charge.

(3) This flowmeter is manufactured, adjusted, and inspected to meet the conditions of use. The fluid

measured, flow range, pressure, temperature, or the like must be applied under the specified conditions.

The conditions for use are stated in the nameplate attached to the flowmeter transmitter and specification

sheet supplied with the product.

Items Stated on the Nameplate