D-555-3-E

2

CONTENTS

1. BEFORE YOU BEGIN............................................................................................. 4

1.1 Conrming the Nameplate .............................................................................................................4

1.2 Transportation Considerations.......................................................................................................4

1.3 Storage Considerations .................................................................................................................4

2. OPERATING CONDITIONS.................................................................................... 5

3. GENERAL ............................................................................................................... 5

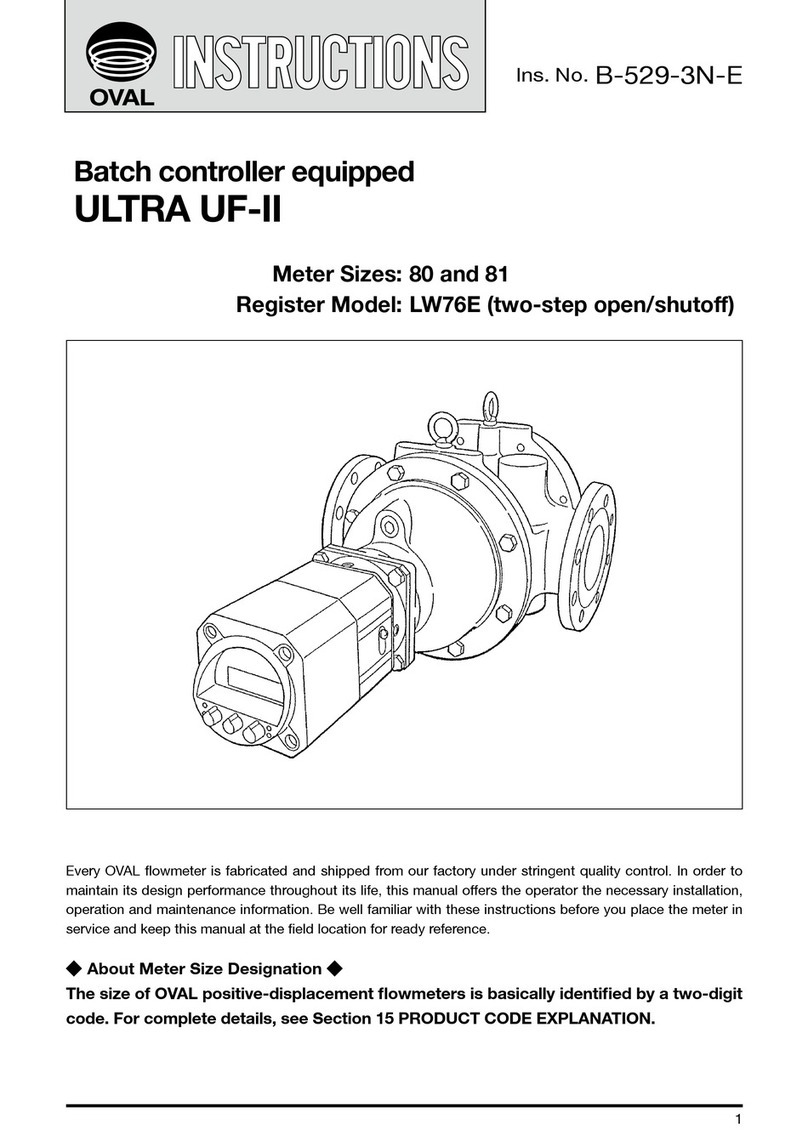

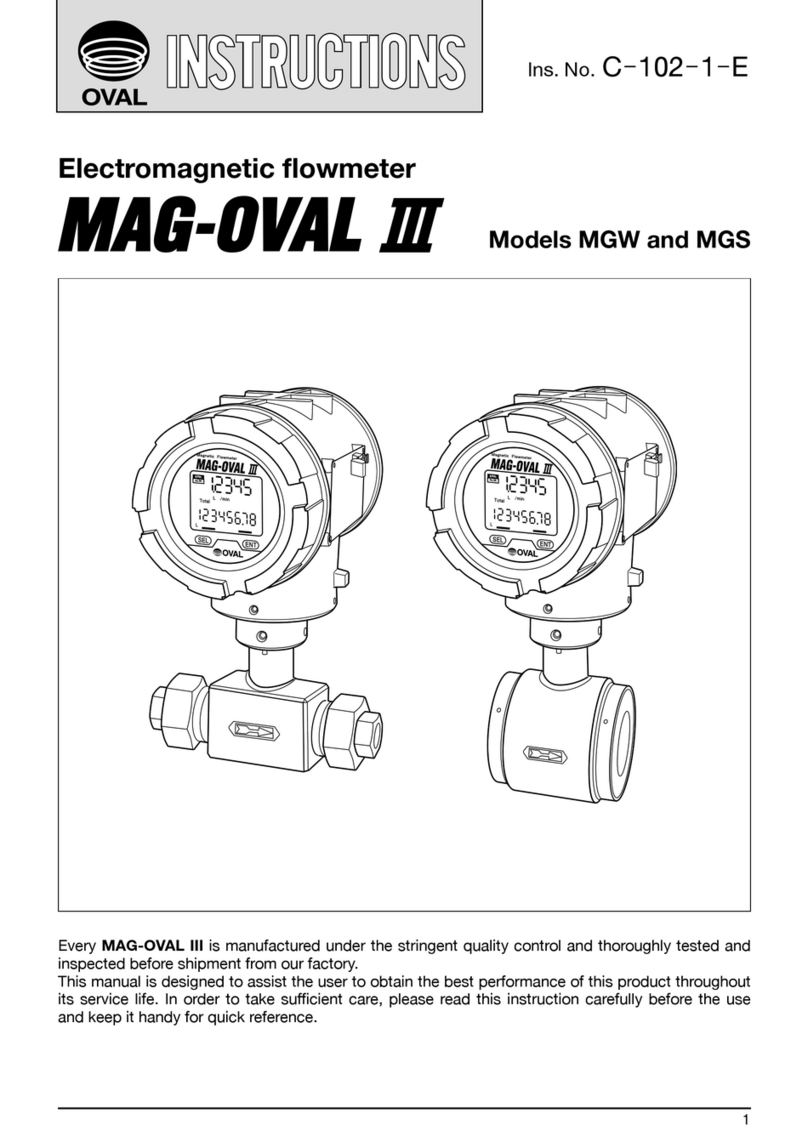

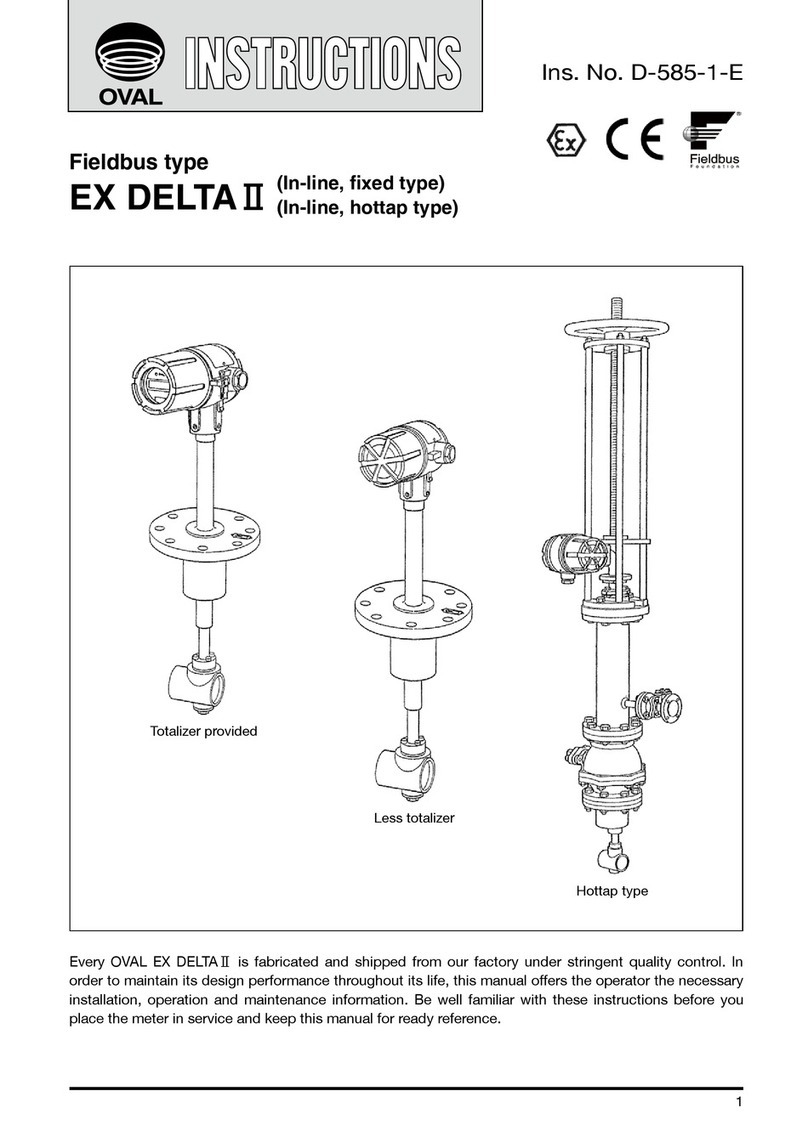

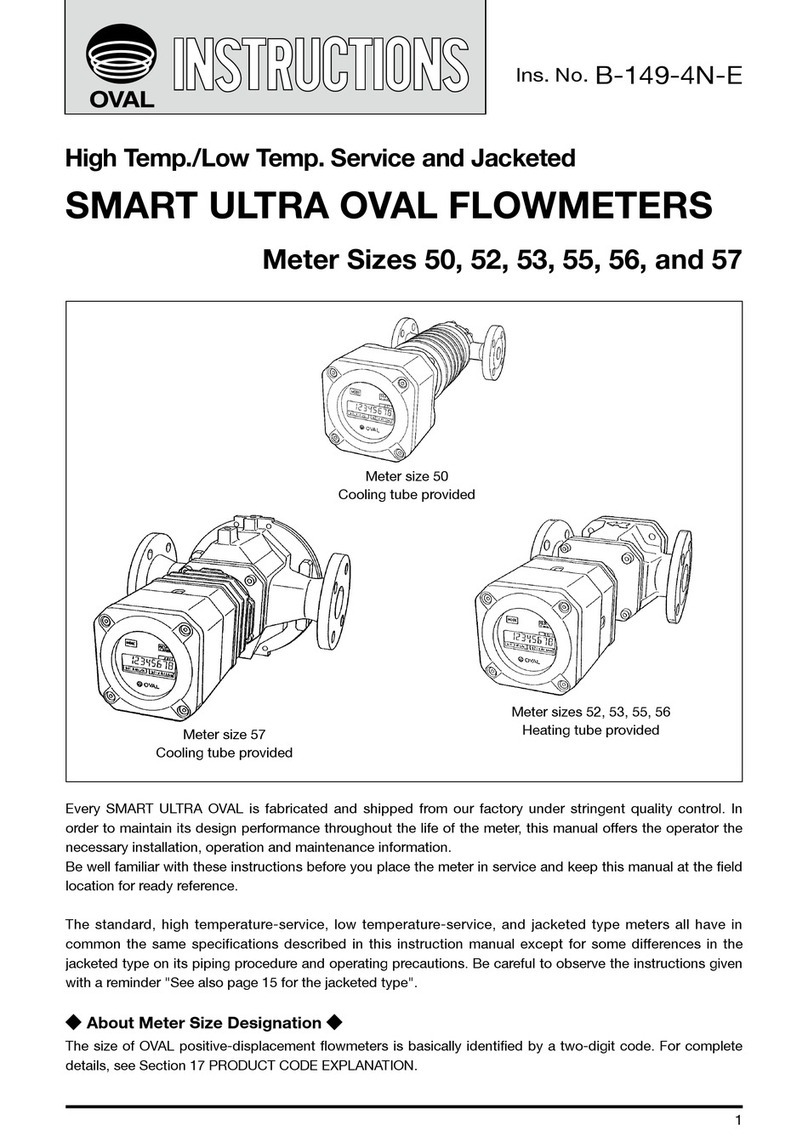

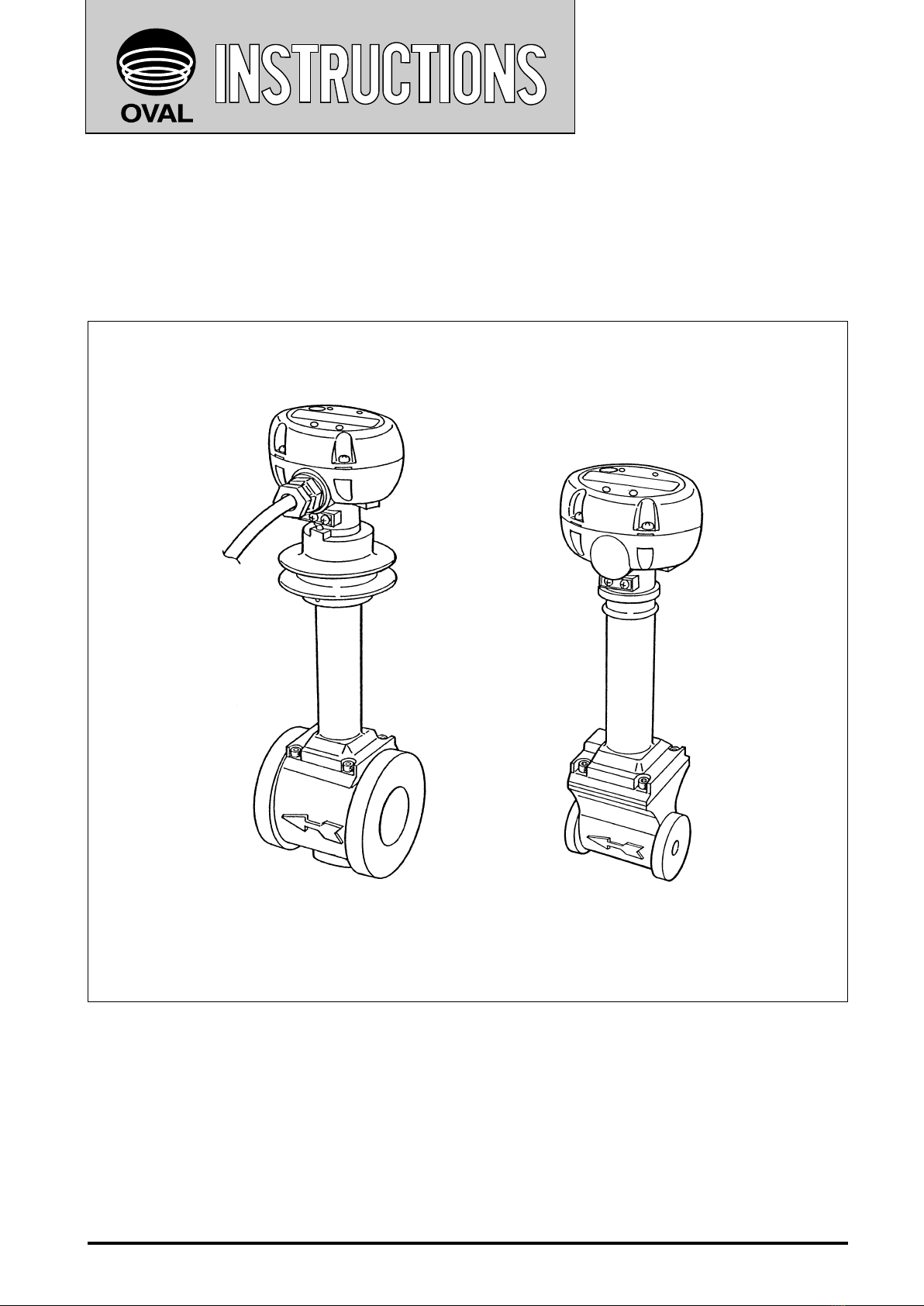

4. PART NAMES AND FUNCTIONS .......................................................................... 5

4.1 Part Names ....................................................................................................................................5

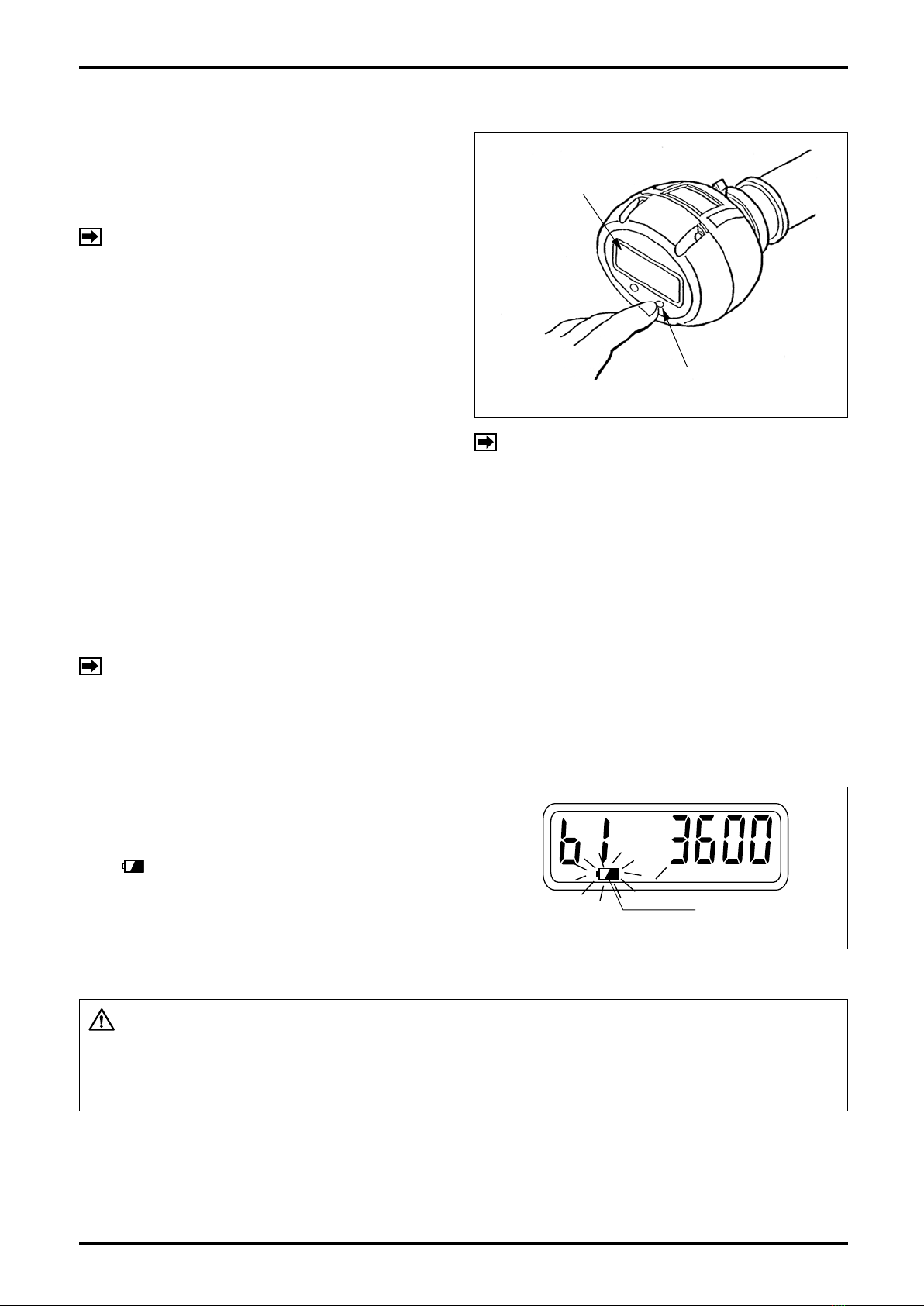

4.2 Display Functions and Operation...................................................................................................7

4.2.1 Display Menu Selection ...........................................................................................................7

4.2.2 About the Displayed Messages during Operation ...................................................................7

4.2.3 Total Counter Reset .................................................................................................................8

4.2.4 About the Measurement Units .................................................................................................8

4.2.5 Low Battery Alarm Indication...................................................................................................8

5. PIPING INSTRUCTIONS ........................................................................................ 9

5.1 Standard Piping Conditions ...........................................................................................................9

5.2 Pipes to be Used..........................................................................................................................11

5.3 Location of Pressure Gauge and Thermometer Taps ..................................................................11

5.4 Pulsations ....................................................................................................................................11

5.5 Prevention of Cavitation (liquid service).......................................................................................11

5.6 Prevention of Excessive Flowrate ................................................................................................12

5.7 Prevention of Slug Flow ...............................................................................................................12

5.8 Partially Filled Pipe.......................................................................................................................12

5.9 Bypass Line..................................................................................................................................12

6. INSTALLATION ..................................................................................................... 13

6.1 Installation Location .....................................................................................................................13

6.2 Physical Orientation .....................................................................................................................13

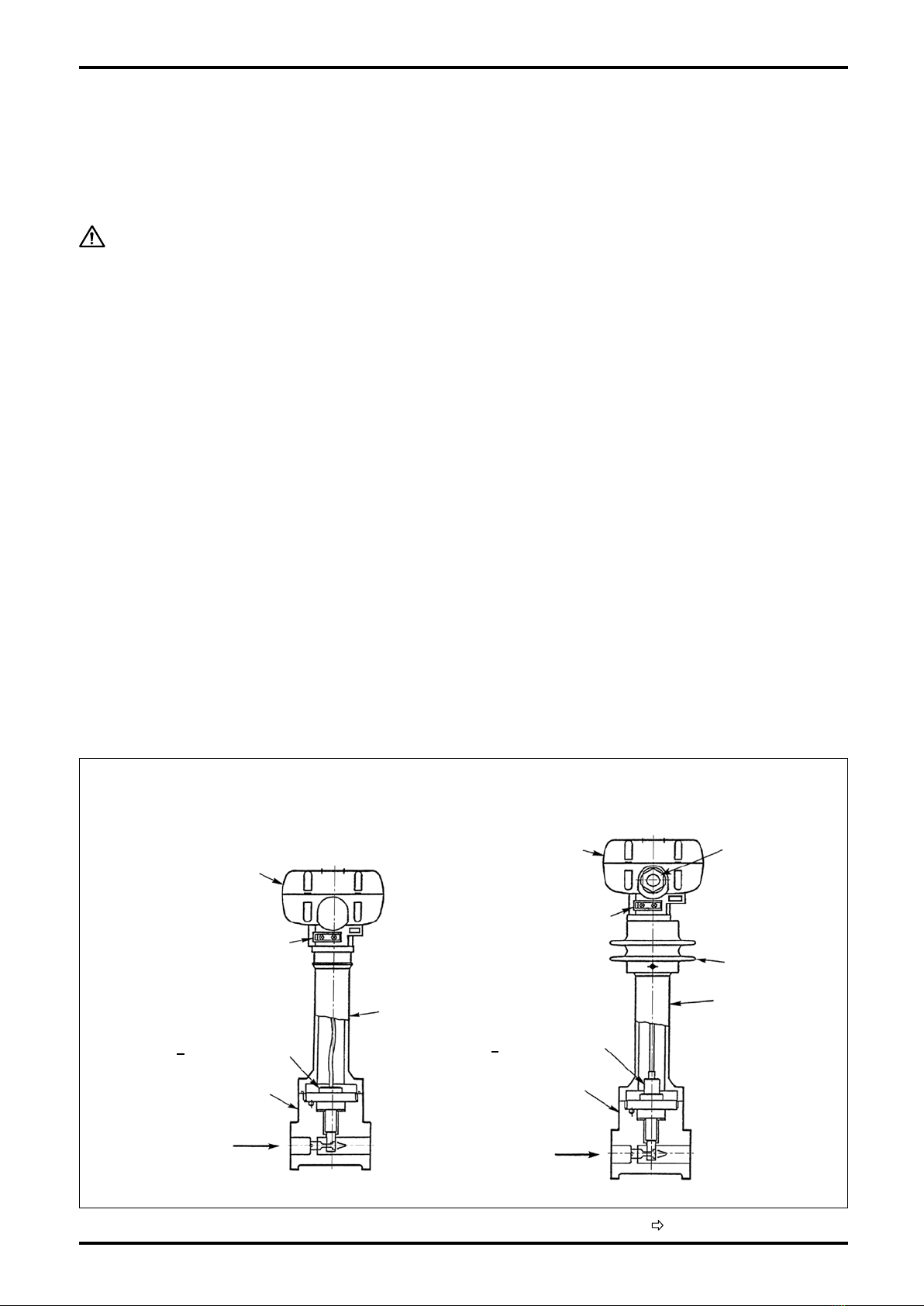

6.3 How to Change Preamplier Orientation................................................................................................. 13

6.4 Lagging Work ...............................................................................................................................13

6.5 Installation Procedure ..................................................................................................................14

6.6 Wiring Diagrams...........................................................................................................................15

7. OPERATION.......................................................................................................... 16

7.1 Flushing the Piping Assembly......................................................................................................16

7.2 Operation Procedure....................................................................................................................16

8. ABOUT CONFIGURATION OF PARAMETERS ................................................... 17

8.1 Parameters List ...........................................................................................................................17

8.2 Parameter Setup Procedure.........................................................................................................19

8.2.1 Procedure to modify a parameter ..........................................................................................19

8.2.2 Procedure to Enter a Parameter ............................................................................................19

8.2.3 About Alarm Outputs .............................................................................................................22

8.2.4 About Dummy Output Functions (special functions) .............................................................23

8.2.5 Parameter Initialization...........................................................................................................23

8.3 About the Error Messages ...........................................................................................................24

Table 8.4 Menu Trees and Switch Operation ..................................................................................25