Ozito TSF-1211U User manual

Other Ozito Saw manuals

Ozito

Ozito BSW-2581U User manual

Ozito

Ozito OZMCS2000WB User manual

Ozito

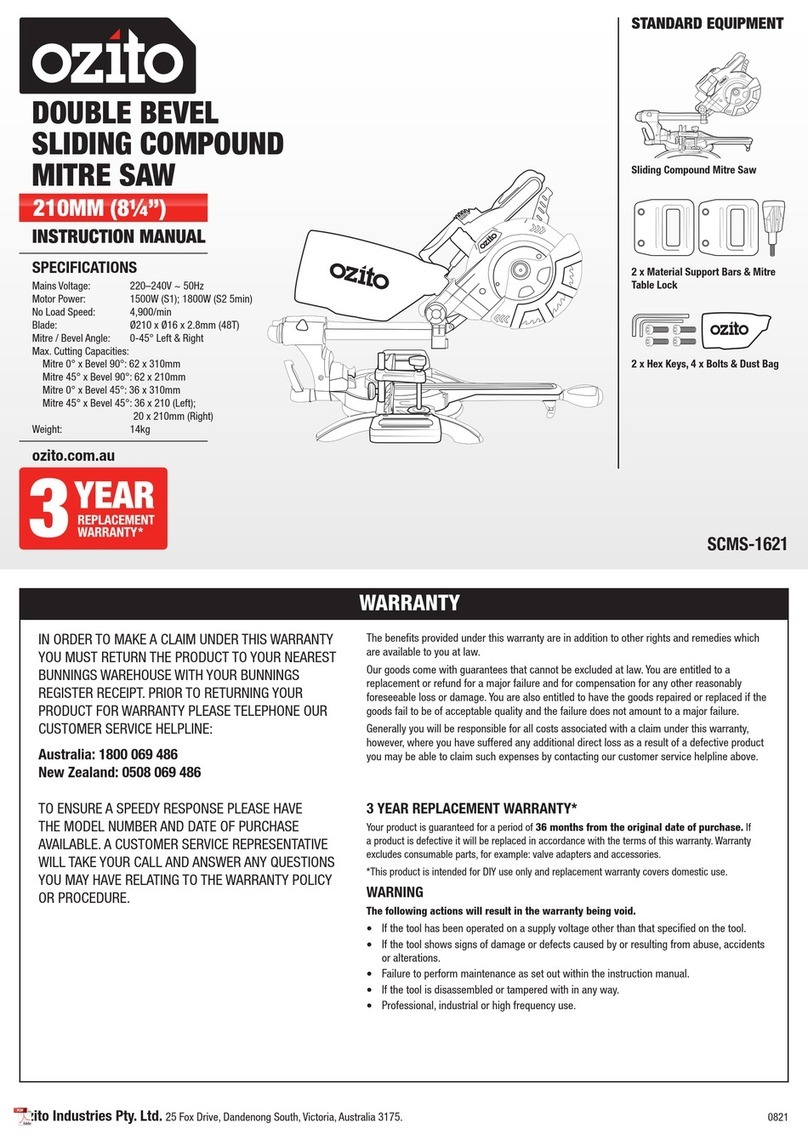

Ozito SCMS-1621 User manual

Ozito

Ozito PXRSS-400 User manual

Ozito

Ozito CMS-1621 User manual

Ozito

Ozito UMS-1810 S User manual

Ozito

Ozito PXCPRSK-218U User manual

Ozito

Ozito XPXC PXBRSS-018 User manual

Ozito

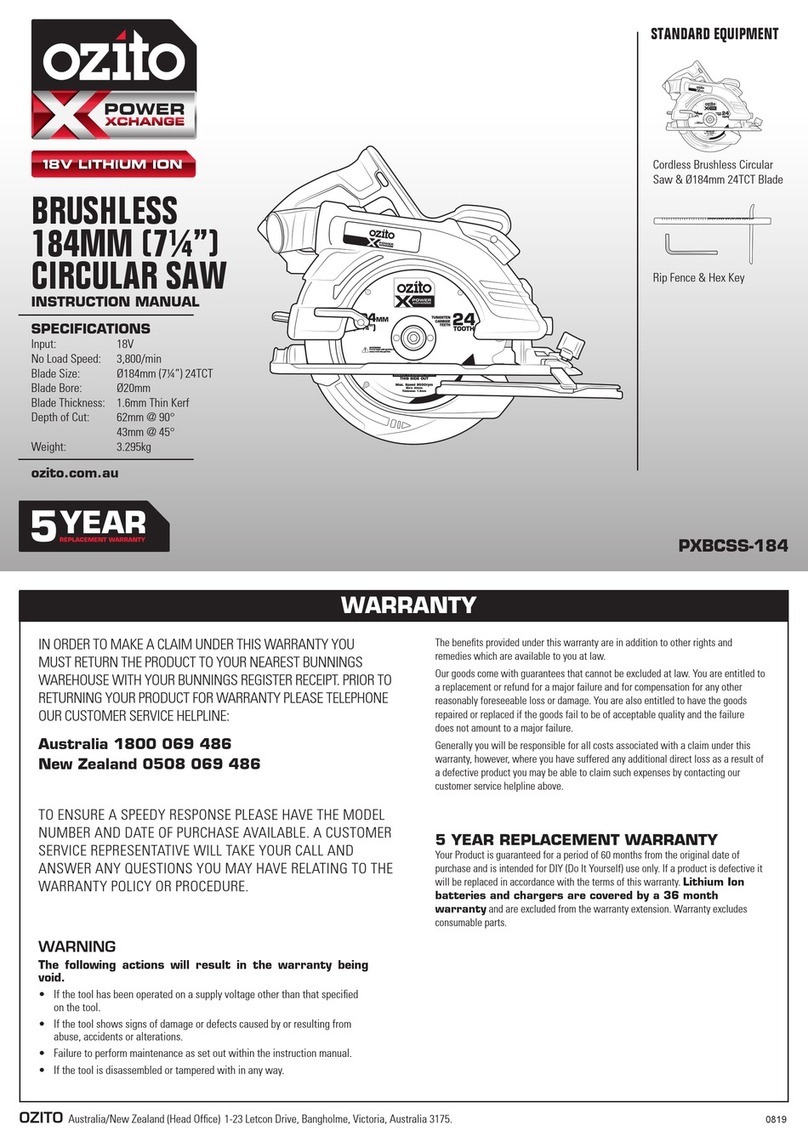

Ozito Power X Change PXBCSS-184 User manual

Ozito

Ozito tsb-0808 User manual

Ozito

Ozito SSB-405 User manual

Ozito

Ozito TCS-115 User manual

Ozito

Ozito CSW-7000 User manual

Ozito

Ozito PXC PXSMSS-036 User manual

Ozito

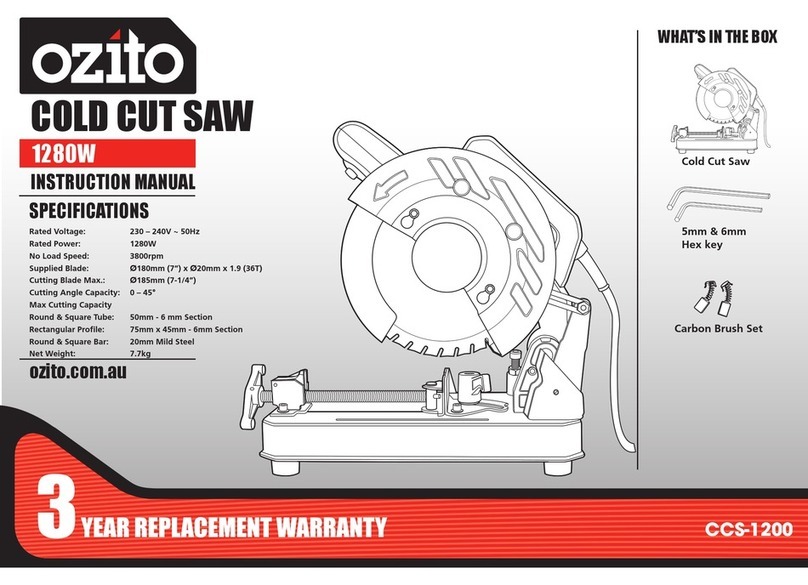

Ozito OZCS1200WA User manual

Ozito

Ozito CMS-1621U User manual

Ozito

Ozito RSG-491VK User manual

Ozito

Ozito ZLRSS-012 User manual

Ozito

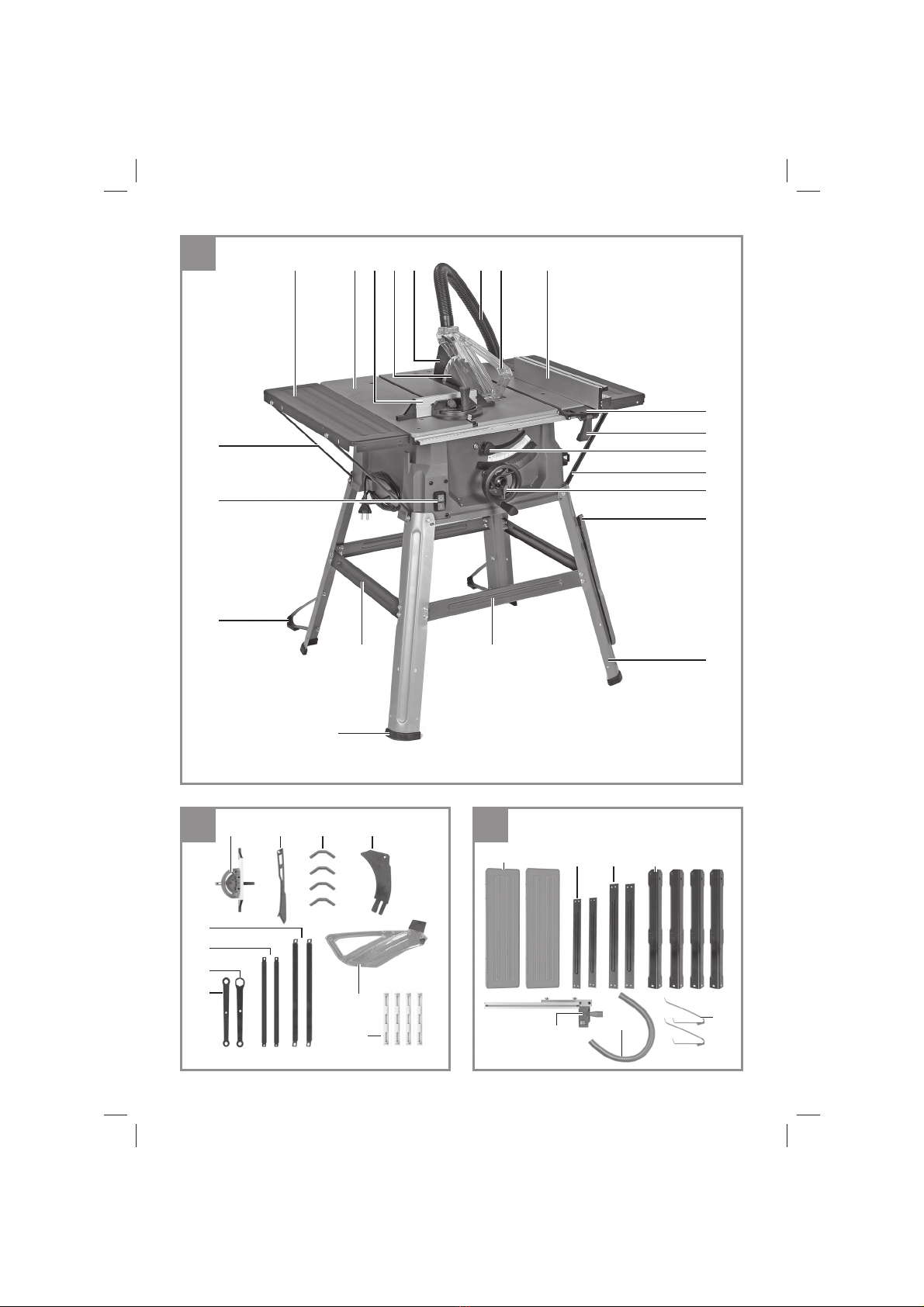

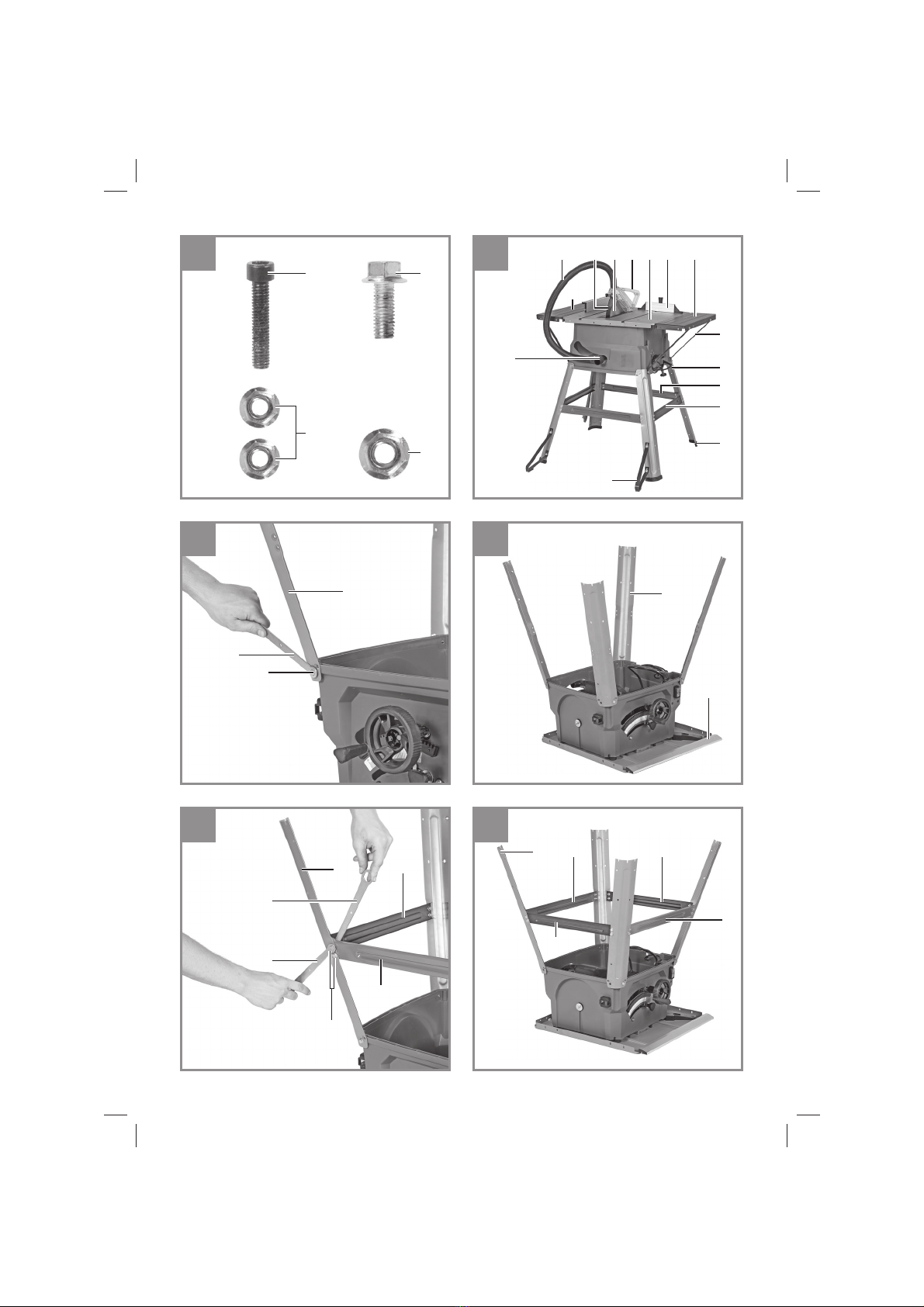

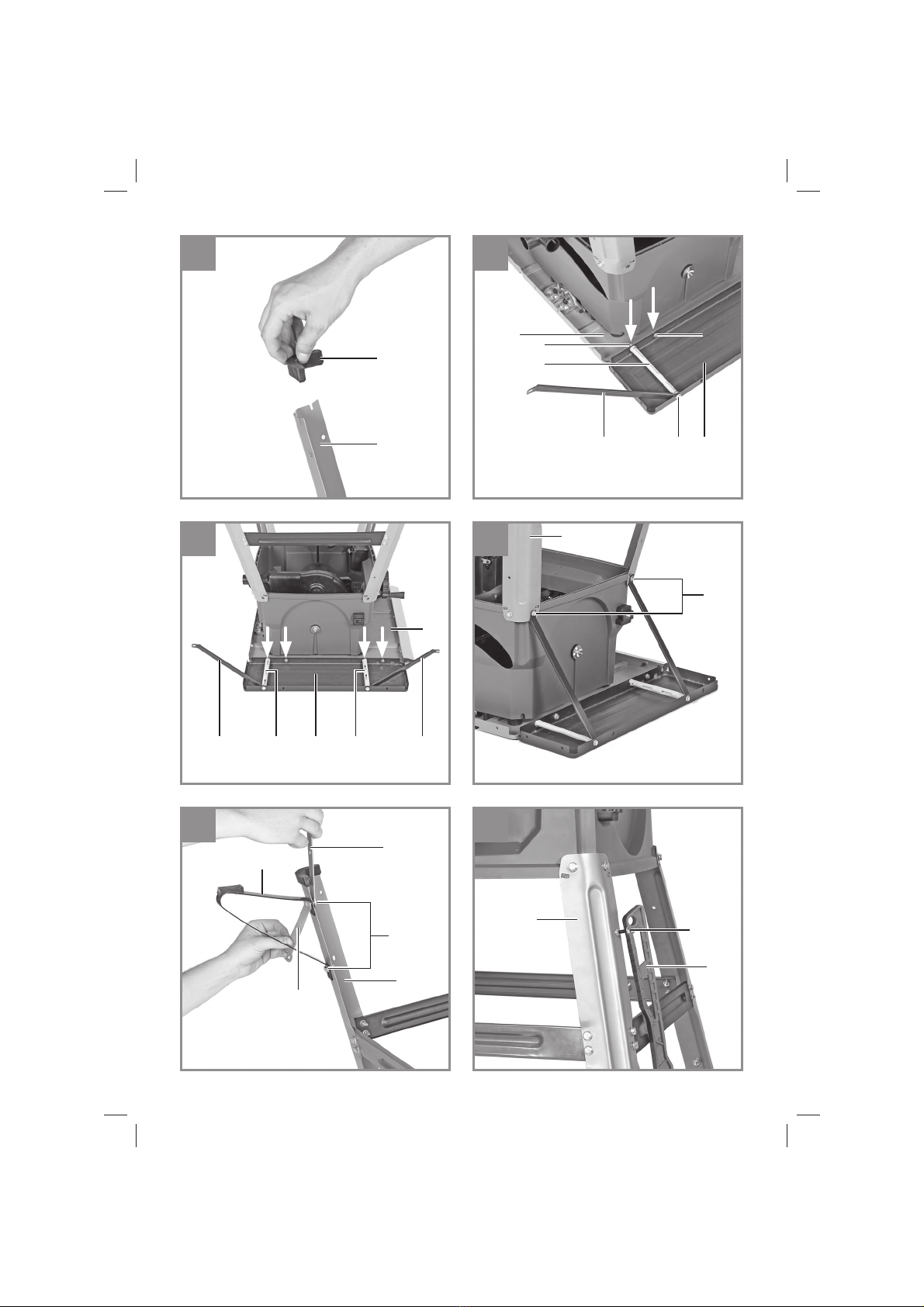

Ozito TSF-1211U User manual

Ozito

Ozito JSW-8100 User manual