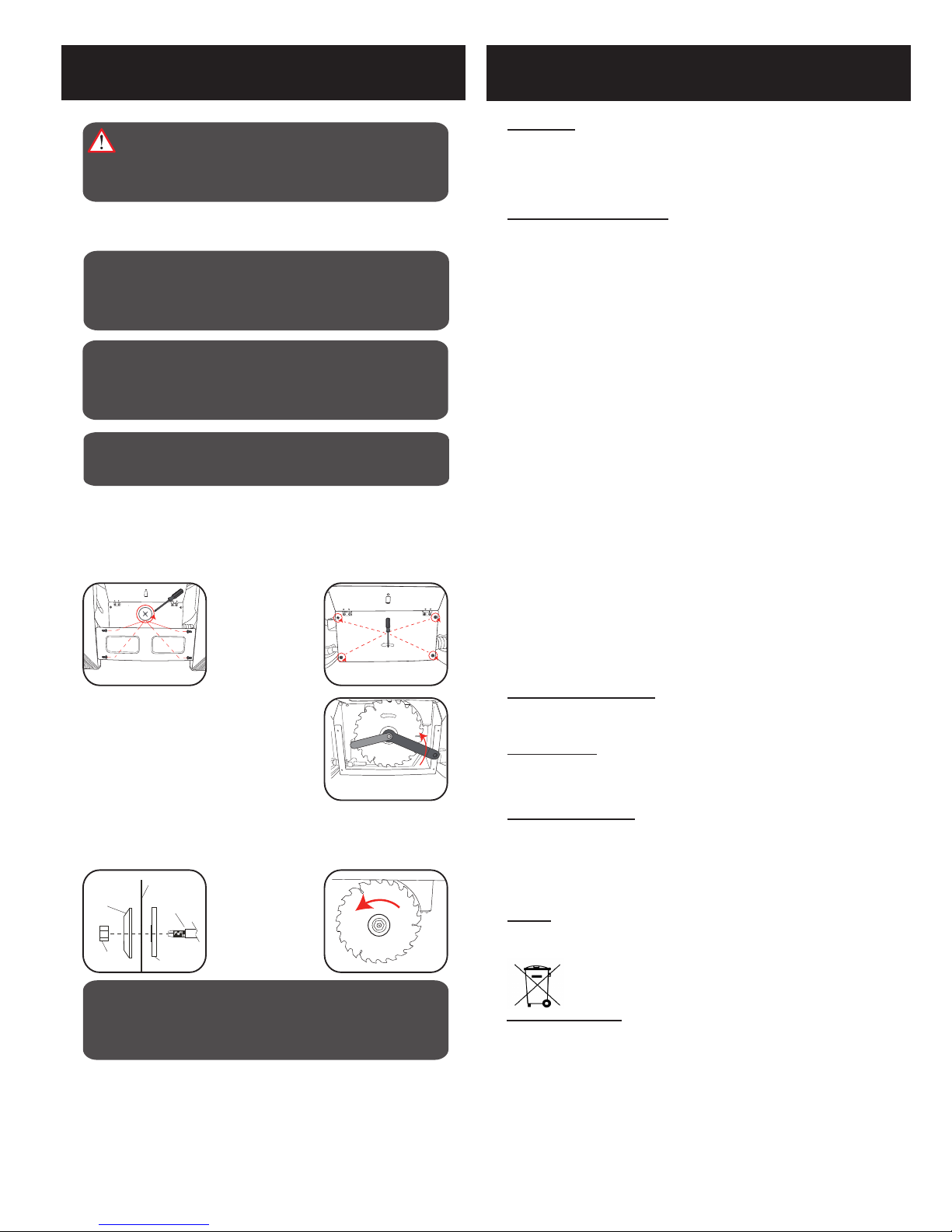

DESCRIPTION OF SYMBOLS

SPARE PARTS

VVolts Hz

~Alternating current W

/min Revolutions or

reciprocation per minute

no

Warning

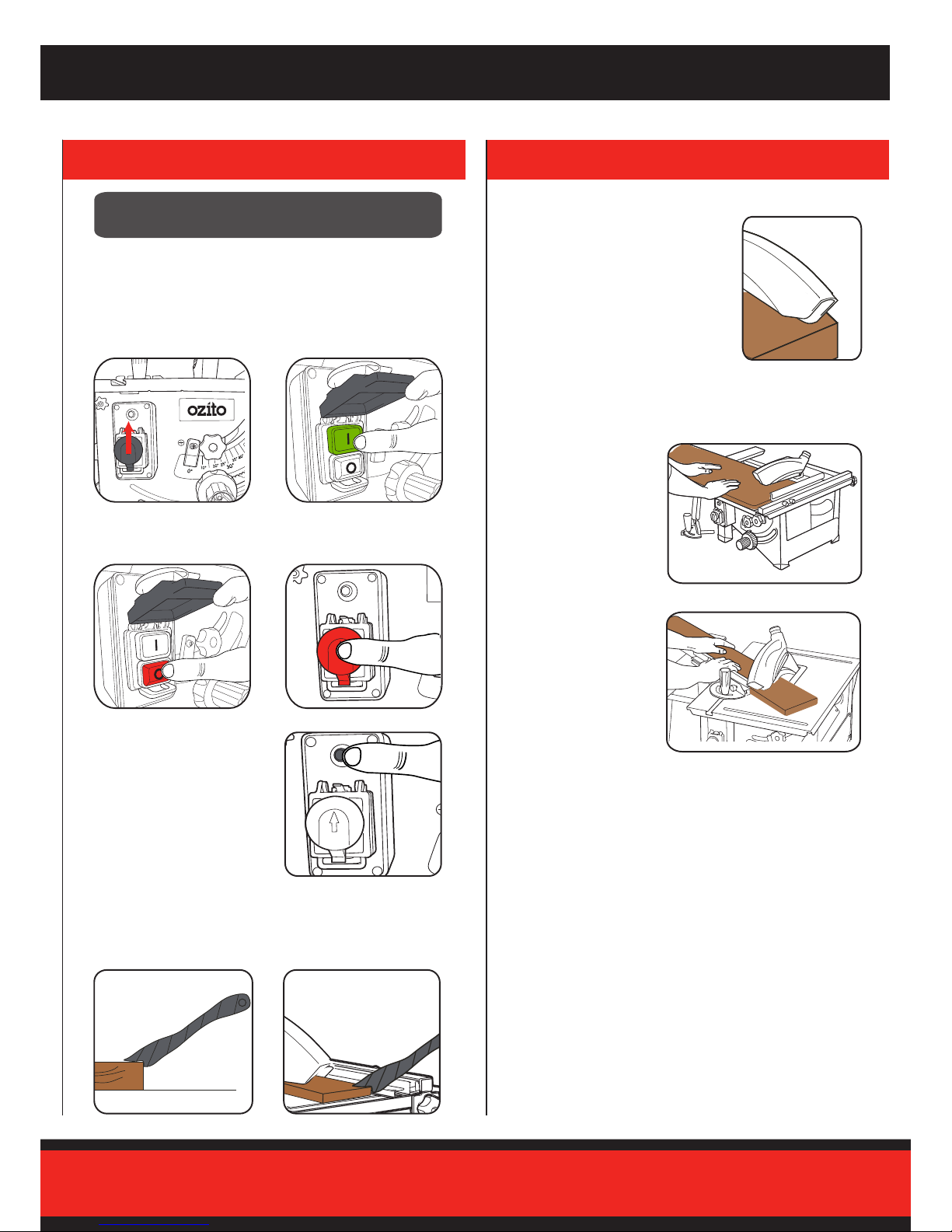

Caution! Risk of injury! Do not reach into the running saw blade.

Danger! - Read the operating instructions to reduce the risk of inquiry.

Caution! Wear a breathing mask. Dust which is injurious to health can be

generated when working on wood and other materials. Never use the device to

work on any materials containing asbestos!

Caution! Wear ear-muffs. The impact of noise can cause damage to hearing.

Caution! Wear safety goggles. Sparks generated during working or splinters,

chips and dust emitted by the device can cause loss of sight.

Hertz

Watts

No load speed

Double insulated

Spare parts can be ordered from the Special Orders Desk

at your local Bunnings Warehouse or Homebase store.

For further information, or any parts visit

www.ozito-diy.co.uk or contact Ozito Customer Service:

Great Britain: 0151 294 4488

Ireland: 1850 882711

E-mail: enquires@ozito-diy.co.uk

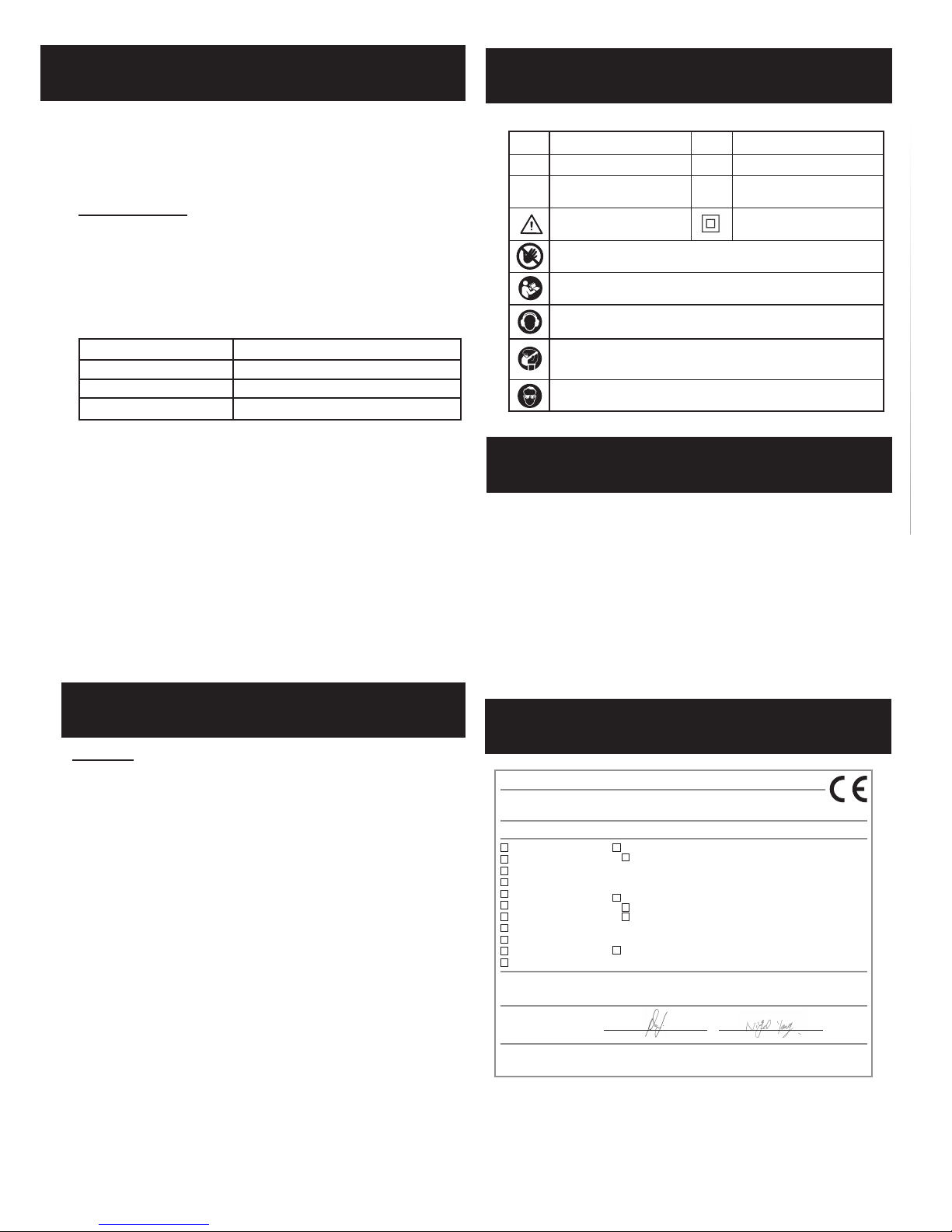

DECLARATION OF CONFIRMITY

Yang/Product-ManagementWeichselgartner/General-Manager

explains the following conformity according to EU directives and norms for

the following product

Table Saw TSB-0808U (Ozito)

2014/29/EU

2005/32/EC_2009/125/EC

2014/35/EU

2006/28/EC

X2014/30/EU

2014/32/EU

2014/53/EC

2014/68/EU

90/396/EC_2009/142/EC

89/686/EC_96/58/EC

X2011/65/EU

X2006/42/EC

XAnnex IV

Notied Body: TÜV Süd Product Service GmbH

Ridlerstraße 65, D-80339 München, Germany

Notied Body No.: 0123

Reg. No.: xxx xx xx xxxxx xxxxx

2000/14/EC_2005/88/EC

Annex V

Annex VI

Noise: measured LWA = dB (A); guaranteed LWA = dB (A)

P = KW; L/Ø = cm

Notied Body:

2012/46/EU

Emission No.:

Standard references: EN 61029-1; EN 61029-2-1; EN 55014-1;

EN 55014-2; EN 61000-3-2; EN 61000-3-3

Landau/Isar, den 25.08.2016

First CE: 16 Archive-File/Record: NAPR014443

Art.-No.: 43.404.20 I.-No.: 11016 Documents registrar: R. Gehard

Subject to change without notice Wiesenweg 22, D-94405 Landau/Isar

ISC GmbH · Eschenstraße 6 · D-94405 Landau/Isar

The reprinting or reproduction by any other means, in whole or in part, of

documentation and papers accompanying products is permitted only with the

express consent of the iSC GmbH.

Subject to technical changes

Service information

We have competent service partners in all countries named on the guarantee

certicate whose contact details can also be found on the guarantee certicate.

These partners will help you with all service requests such as repairs, spare and

wearing part orders or the purchase of consumables.

Please note that the following parts of this product are subject to normal or

natural wear and that the following parts are therefore also required for use as

consumables.

Category Example

Wear parts* V-belt, carbon brushes, table insert, push stick

Consumables* Saw blade

Missing parts

* Not necessarily included in the scope of delivery!

In the effect of defects or faults, please register the problem on the internet at www.

isc-gmbh.info. Please ensure that you provide a precise description of the problem

and answer the following questions in all cases:

• Did the equipment work at all or was it defective from the beginning?

• Did you notice anything (symptom or defect) prior to the failure?

• What malfunction does the equipment have in your opinion (main symptom)?

Describe this malfunction.

PROPER USE

Proper use

The bench-type circular saw is designed for the slitting and cross-cutting (only with

the cross stop) of all types of timber commensurate with the machine‘s size. The

equipment is not to be used for cutting any type of round wood.

The equipment is to be used only for its prescribed purpose. Any other use is deemed

to be a case of misuse. The user / operator and not the manufacturer will be liable for

any damage or injuries of any kind caused as a result of this.

Please note that our equipment has not been designed for use in commercial,

trade or industrial applications. Our warranty will be voided if the machine is used in

commercial, trade or industrial businesses or for equivalent purposes.

The equipment is to be operated only with suitable saw blades (saw blades made of

HM or CV) It is prohibited to use any type of HSS saw blade and cutting-off wheel.

To use the equipment properly you must also observe the safety information, the

assembly instructions and the operating instructions to be found in this manual.

All persons who use and service the equipment have to be acquainted with these

operating instructions and must be informed about the equipment‘s potential hazards.

It is also imperative to observe the accident prevention regulations in force in your

area. The same applies for the general rules of health and safety at work. The

manufacturer will not be liable for any changes made to the equipment nor for any

damage resulting from such changes. Even when the equipment is used as prescribed

it is still impossible to eliminate certain residual risk factors. The following hazards may

arise in connection with the machine‘s construction and design:

• Contact with the saw blade in the uncovered saw zone.

• Reaching into the running saw blade (cut injuries).

• Kick-back of workpieces and parts of workpieces.

• Saw blade fracturing.

• Catapulting of faulty carbide tips from the saw blade.

• Damage to hearing if essential ear-muffs are not used.

• Harmful emissions of wood dust when used in closed rooms.