9

MidiHeat EHD

MA45-33 SE (instruktionens originalspråk)

SVENSKA

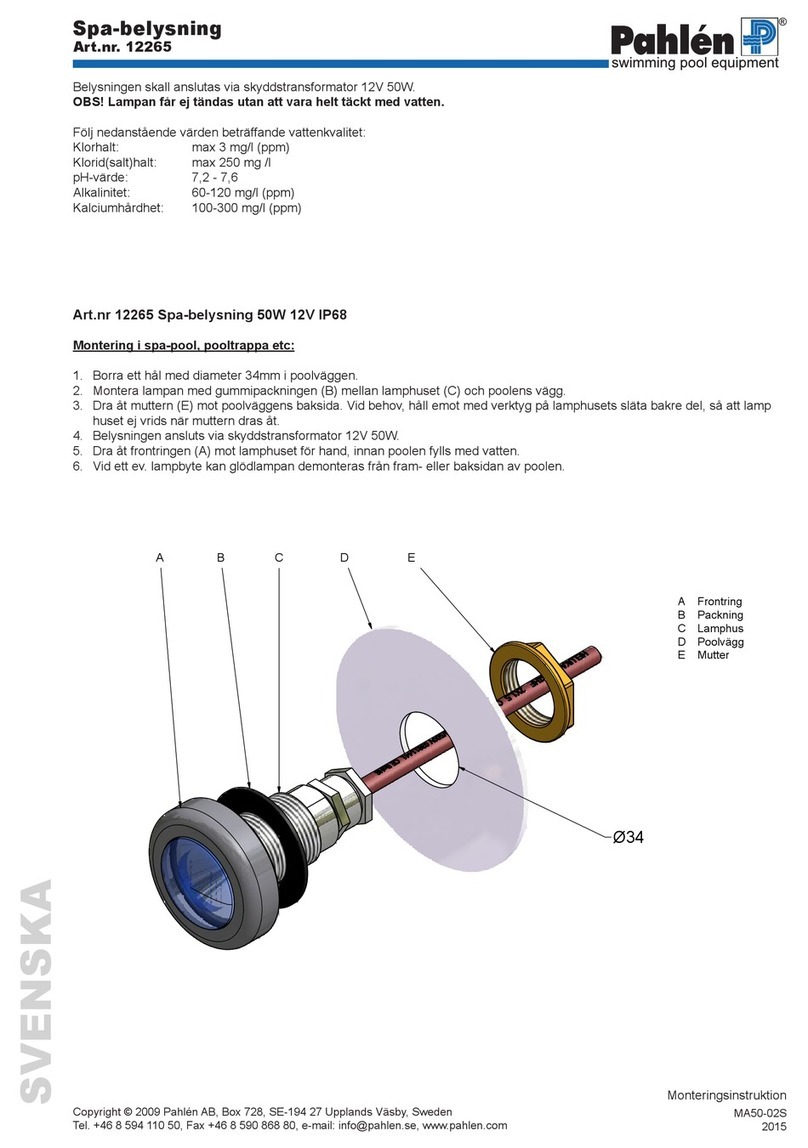

Återställningsknapp

Skyddshuv

A ( 1 : 1 )

This documentanditscontentsaretheexclusive

propertyofPahlénsandmaynotbecopied,

reproduced,transmittedorcommunicatedtoathird

party,orusedforanypurposewithoutwrittenpermission.

Art.no.

Rev.no.

Scale

Designed by: Approved by:

Revised by: Date

Drawn by: Date

Drawing number

Assembly drawing no.

Surface treatment

part of ISO 2768-1

The tolerance class in accordance with this

E

Box 728, SE-194 27 Upplands Väsby, Sweden

Phone +46 8 59411050, Fax +46 8 59086880

TS 2012-06-21

överhettningsskydd

Demontering lock

M11668 0

A

Om fel uppstår

Displayenvisarenfelkod,senedan.Kontaktaerinstallatörförattåtgärdafelet.

Felkoder

Kod Orsak Åtgärd

E1 Flödesvaktenindikerarlågtöde Kontrollera/ökavattenödet

E2 Poolvattentemp.sensorn ej ansluten

alternativtkortsluten/trasig

Kontrollera att temp.sensorn är ansluten.

Byt trasig temp.sensor.

E6

Överhettningsskyddet har löst ut Varning! Enheten är strömförande fram till första kontaktorn även om över-

hettningsskyddet har utlösts.

Återaktivera överhettningsskyddet manuellt

genom att avlägsna den lilla skyddshuven och

tryckainåterställningsknappen.

Om överhettningsskyddet fortsätter att lösa ut:

kontakta er installatör eller en annan

kvaliceradservicetekniker.

E10 Cirkulationspump ej aktiv Sättpåcirkulationspumpen.

E12 Kommunikationsfel KontrollerainställningarnaförkommunikationMaster/Slave.

Kontrollera kommunikationskabeln

HC Förhögtemperaturpåkretskortet Kontrolleraattomgivningstemperatureninteärhögreän40°C.

HP Vattentemperaturen är högre än +45°C Kontrollera att övriga värmekällor inte är aktiverade

VidMaster/slav-styrningvisasfelkodenochensirainomparantesefter.Dettaindikerarvilkenavdeanslutnaenheternasom

har det aktuella felet.

Exempel:E1(2)=indikerarattslavenhet2harettfel.

Med reservation för ev. tryckfel. Rätt till ändringar av tekniska speciaktioner och sortiment förbehålles.

Färgavvikelser kan uppstå av trycktekniska skäl.

Skötsel

Observera att elvärmaren endast arbetar när vattnet i systemet cirkulerar. Den ska inte värma om cirkulationspumpen är

avslagenelleromönskvärdpooltemperaturharuppnåtts.

Omelvärmareninteskavärmapoolvattnetunderenlängreperiodrekommenderasattslåavallahuvudströmbrytare.

Omvattnetisystemetblirstillaståendelängreänenveckaskallelvärmarentömmaspåvatten.

Vidfrysriskskallströmmentillelvärmarenochpumpenslåsavochelvärmarentömmaspåvatten,se“Tömningavelvärmaren”

nedan.

Vidbackspolningochrengöringavpoolsystemetslterskallelvärmarenstängasav.

Iområdenmedhårtvattenkanelvärmarenspatronerfåenkalkbeläggningsomförsämrarelvärmarenseektochpatronernas

livslängd.Kontaktadåenbehörigelektrikersomkaninspekteratankenselpatronerregelbundetochavlägsnasådanbeläggning

när det är nödvändigt.

Tömning av elvärmaren

1. Stängavelvärmarenochslåavallahuvudströmbrytareinnantömning.

2. Stäng avstängningsventilen (pos 12 bild 2).

3. Öppna tömningsventilen (pos 13 bild 2).

4. Lossa sedan elvärmarens utloppsanslutning (märkt med röd pil) lite för att släppa in luft. Elvärmaren rymmer ca 15 liter

vatten.Varobservantpåattalltvattenkommerut.

5. Skruvaåtelvärmarensutloppsanslutningnärelvärmarenärhelttömd.

6. Stäng tömningsventilen.