GHI Type infrared ceramic heaters Contents

Contents

...............................................................................................................................................3

.............................................................................................................................................4

Installer’s responsibilities...................................................................................................................................4

Data board.........................................................................................................................................................4

Corrosive materials............................................................................................................................................4

Standards and laws...........................................................................................................................................5

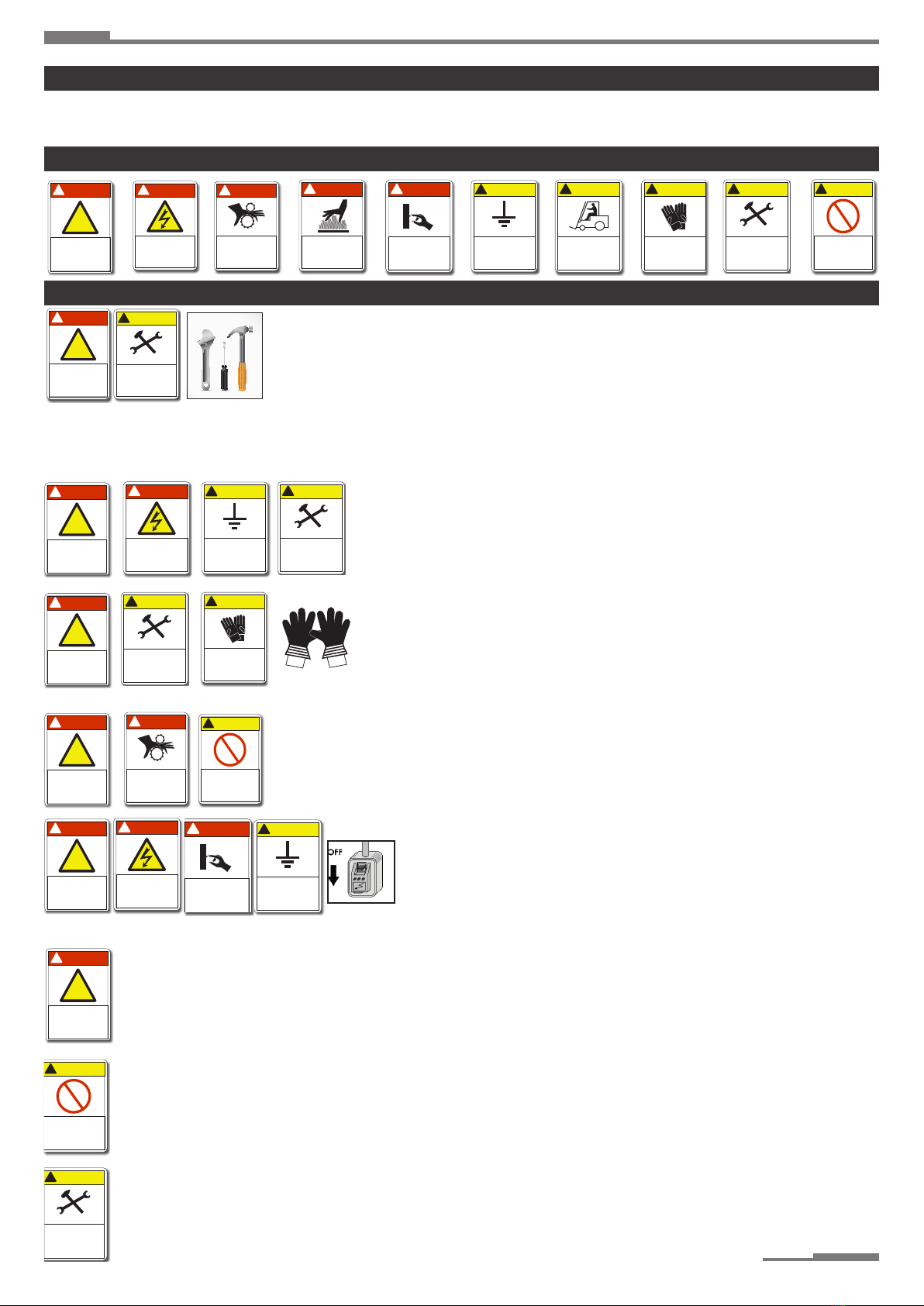

Safety signs.......................................................................................................................................................5

Safe usage ........................................................................................................................................................5

...............................................................................................................6

..............................................................................................................................................6

............................................................................................................................................................7

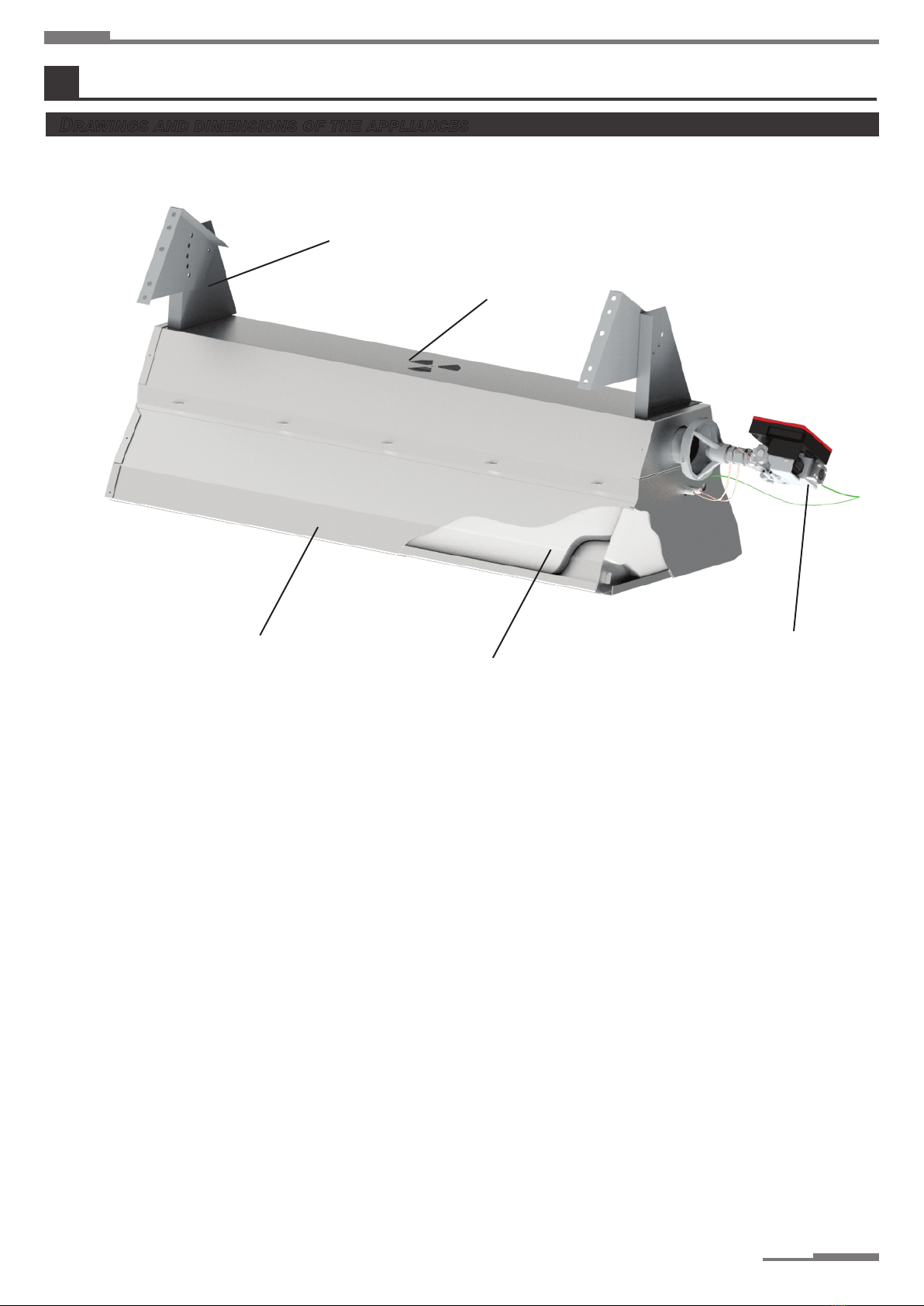

Drawings and dimensions of the appliances .....................................................................................................7

Assemblage process of the appliances.............................................................................................................8

Appliance installation.........................................................................................................................................9

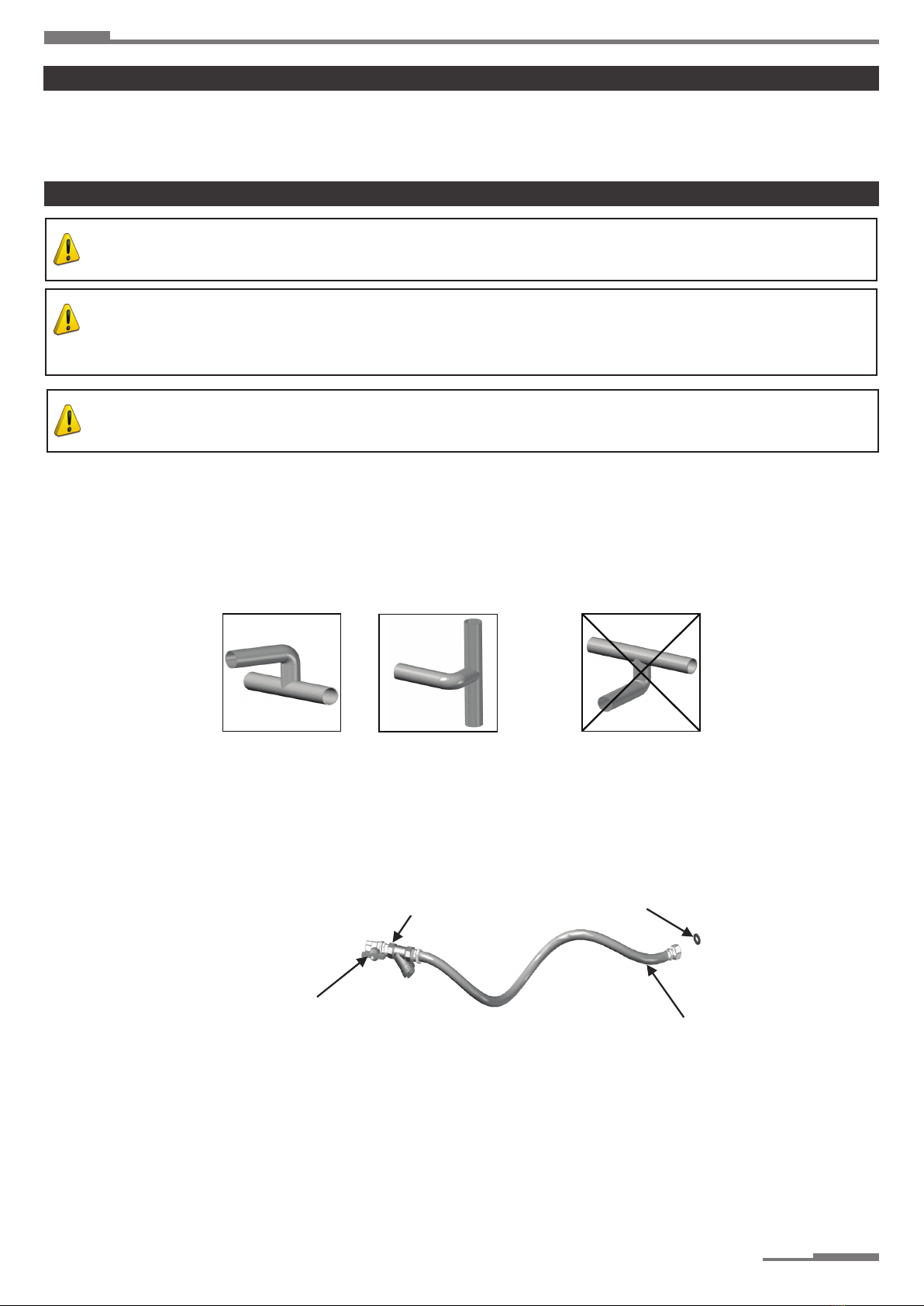

Gas connection..................................................................................................................................................9

Electrical connection........................................................................................................................................10

Regulatory options...........................................................................................................................................10

The solenoid type VK4125C 2005 S4965R2027-type.....................................................................................10

Electrical connection scheme of HONEYWELL S4965R2027 .......................................................................11

control..............................................................................................................................................................11

Optional accessories .......................................................................................................................................11

Suspension......................................................................................................................................................12

...................................................................12

Ventilation ........................................................................................................................................................12

...........................................................................................................................................12

Check at the beginning of season ...................................................................................................................13

Maintenances ..................................................................................................................................................13

Maintenance supervisions by the customer ....................................................................................................14

.........................................................................14

Gas change .....................................................................................................................................................14

..............................................................................................................................................15

Malfunctions ....................................................................................................................................................15

.............................................................................................................................................................16

Enclosure 1.: Type and technical data of infrared heater ................................................................................16

Enclosure 2.: gas consumption of GHI heaters...............................................................................................16

Enclosure 3.: Target countries/gas categories.................................................................................................17

ECO-DESIGN-Declaration of Conformity.........................................................................................................18